Assembled electric detonator

An electric detonator and assembled technology, which is applied in the field of electric detonators and detonating equipment, can solve problems such as high risk, achieve the effects of improving safety, improving accidental detonation of detonators, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

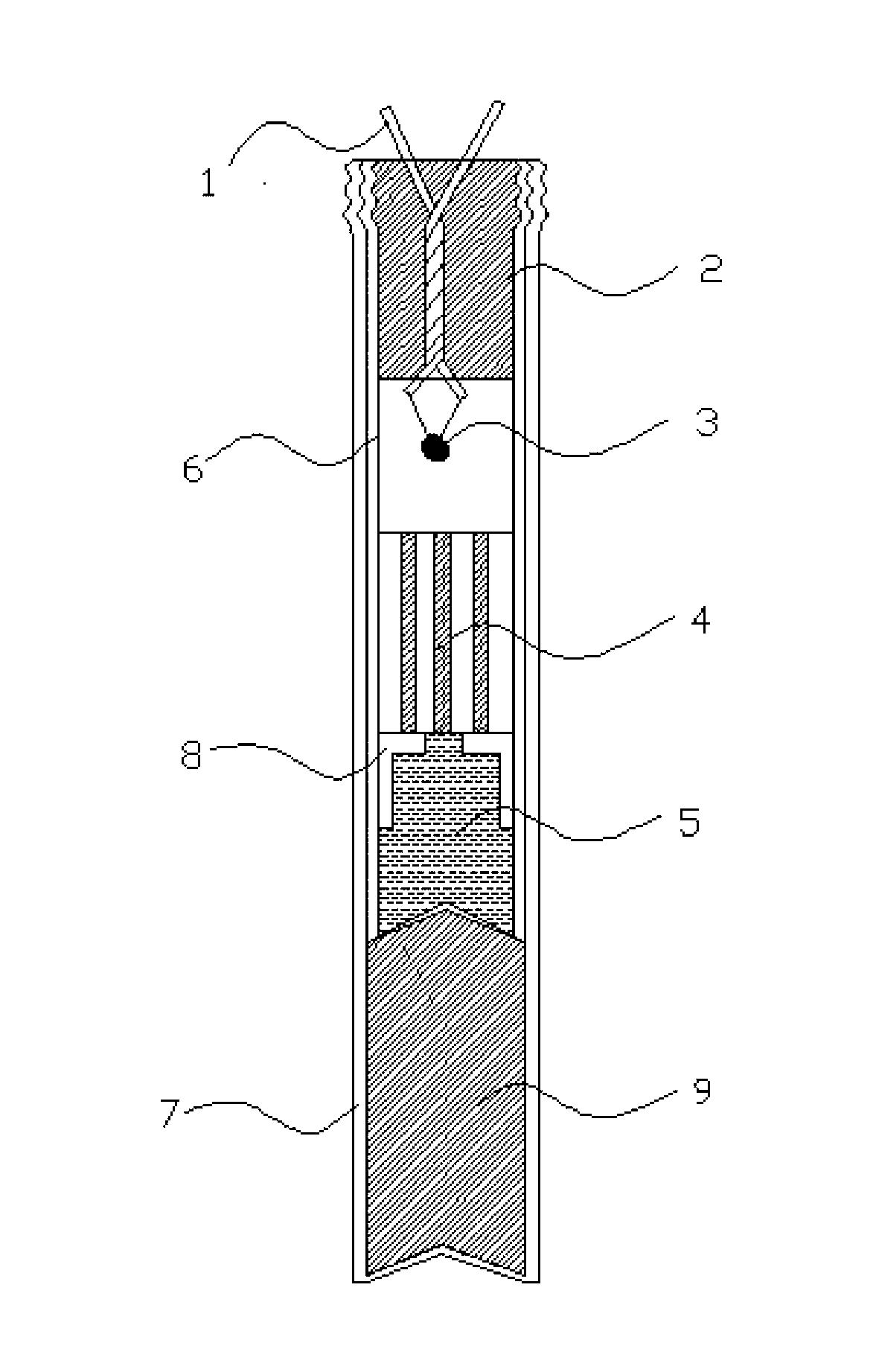

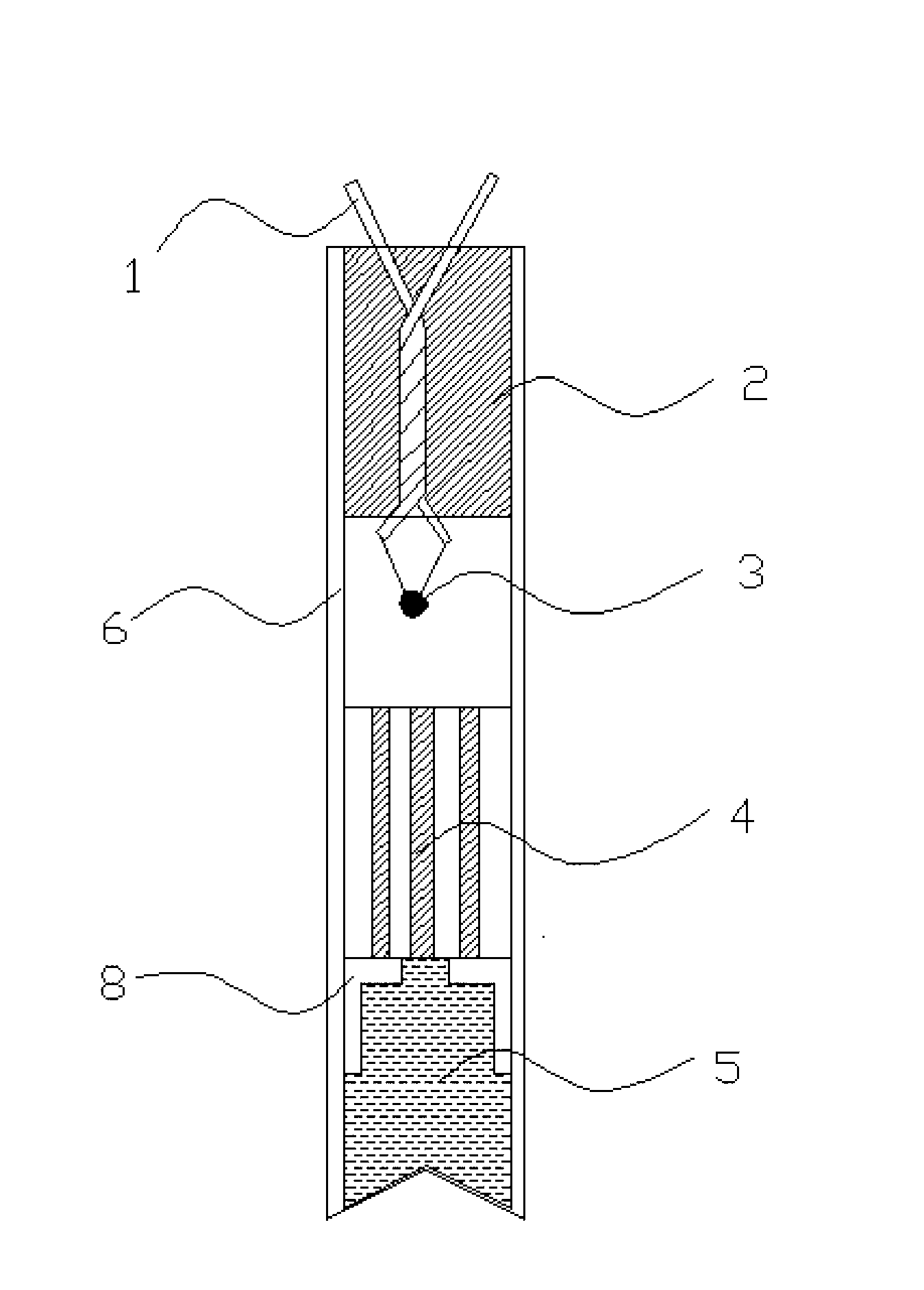

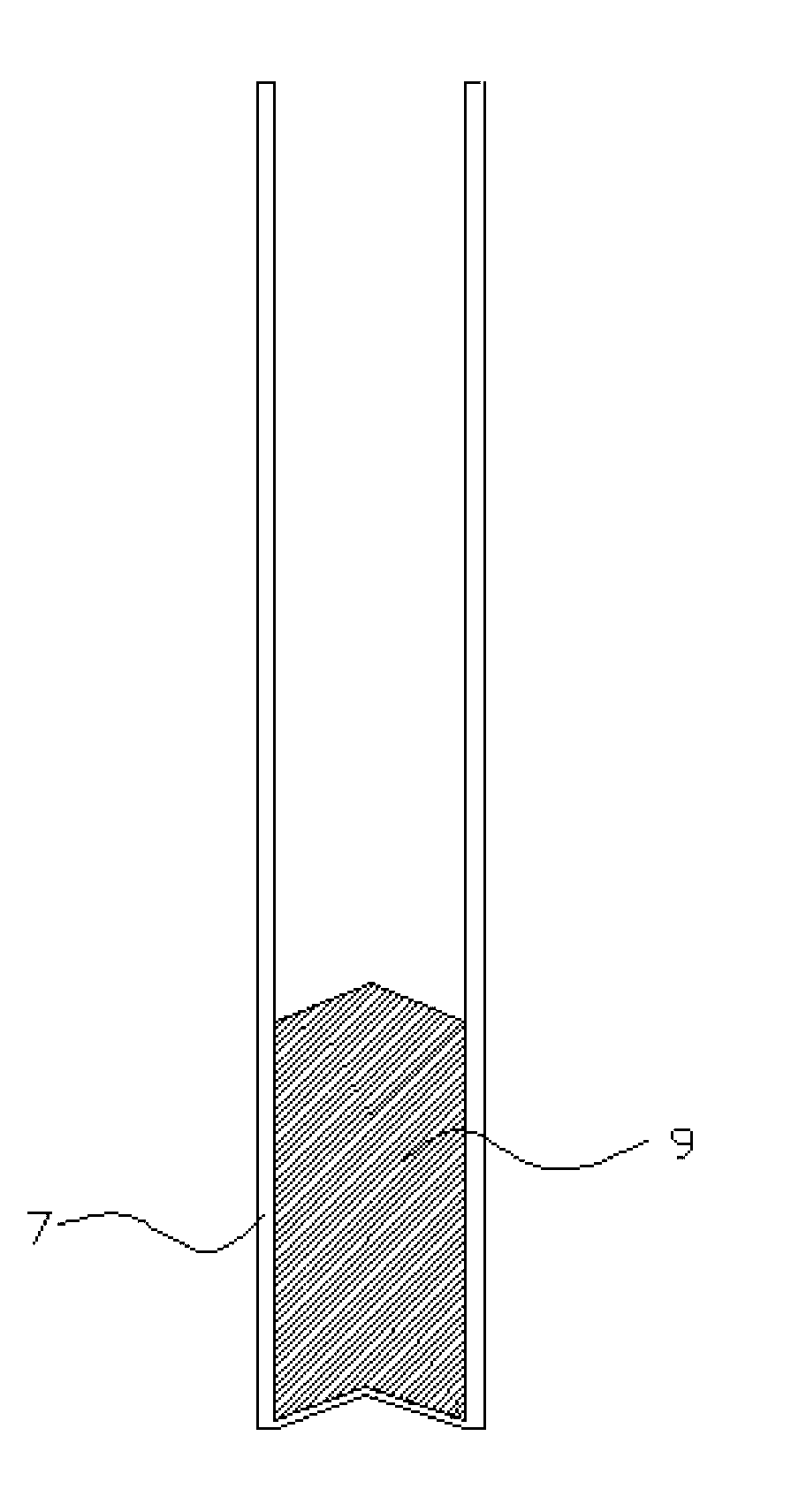

[0018] Such as figure 1 As shown, an assembled electric detonator provided by the present invention is divided into a detonator inner tube and a detonator outer tube. The two parts are separated during production, transportation and storage. The mouth machine can be used like a traditional detonator by bayonet tightening the detonator shell 7, inner shell 6 and bayonet plug 2. The whole detonator includes foot line 1, bayonet plug 2, drug head 3, delay charge 4, and priming charge 5 , inner shell 6, outer shell 7, reinforcement cap 8 and strong explosive 9, combine figure 2 As shown, the inner tube of the detonator includes foot line 1, bayonet plug 2, drug head 3, delay charge 4, priming charge 5, inner shell 6 and reinforcement cap 8, and the priming charge 5 is pressed in the processed detonator inner shell 6 in advance , the delay charge 4 is separated from the priming charge 5 by a reinforcing cap 8 to ensure the compression structure and density of the priming charge 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com