Operation and consumption optimization method based on boiler safety analysis

A technology of operation optimization and optimization method, applied in the direction of instruments, biological neural network models, data processing applications, etc., can solve the problems of out-of-link safe operation of power plants, ignorance of operating personnel, and failure to take into account the safety analysis of power plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

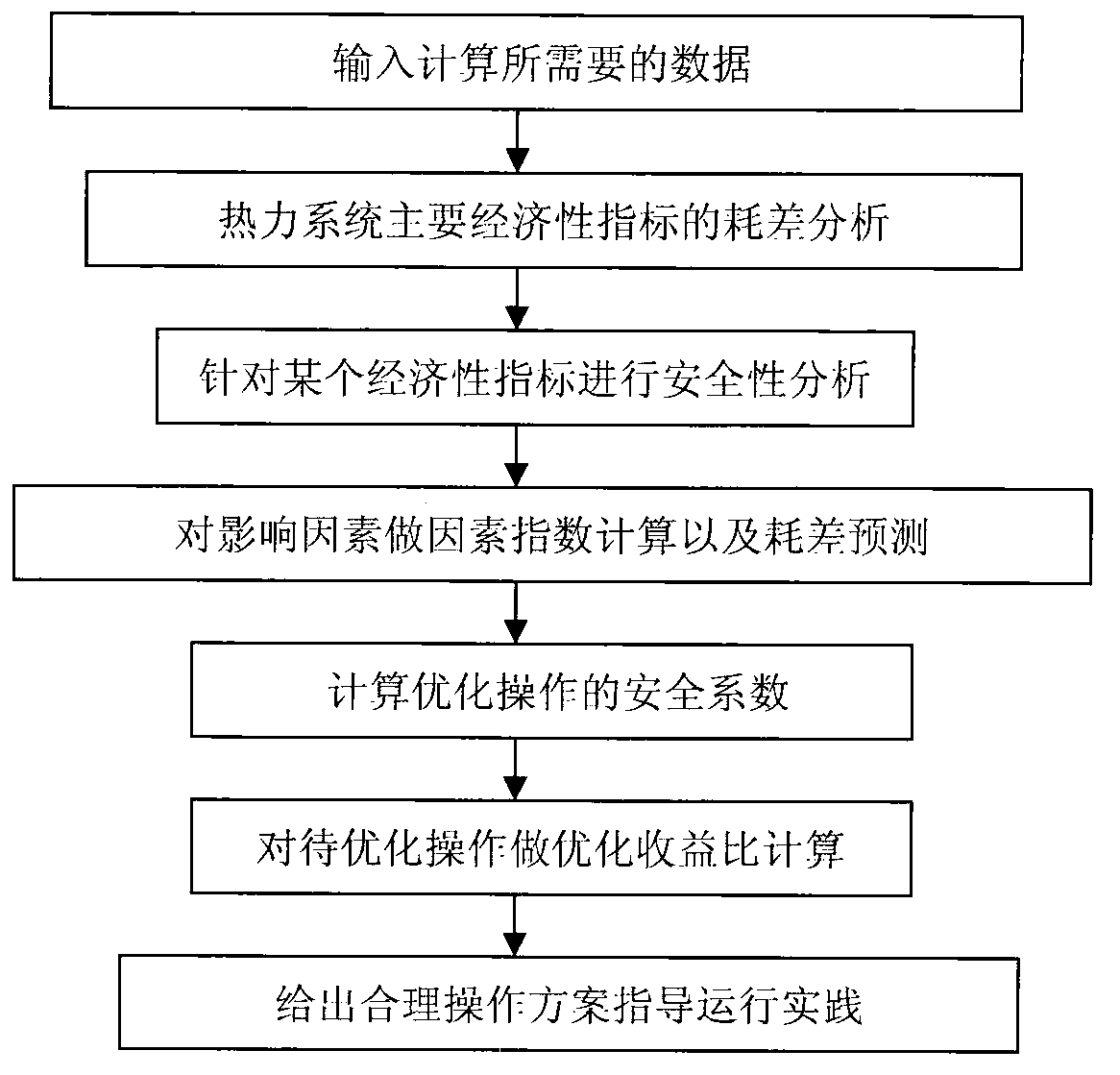

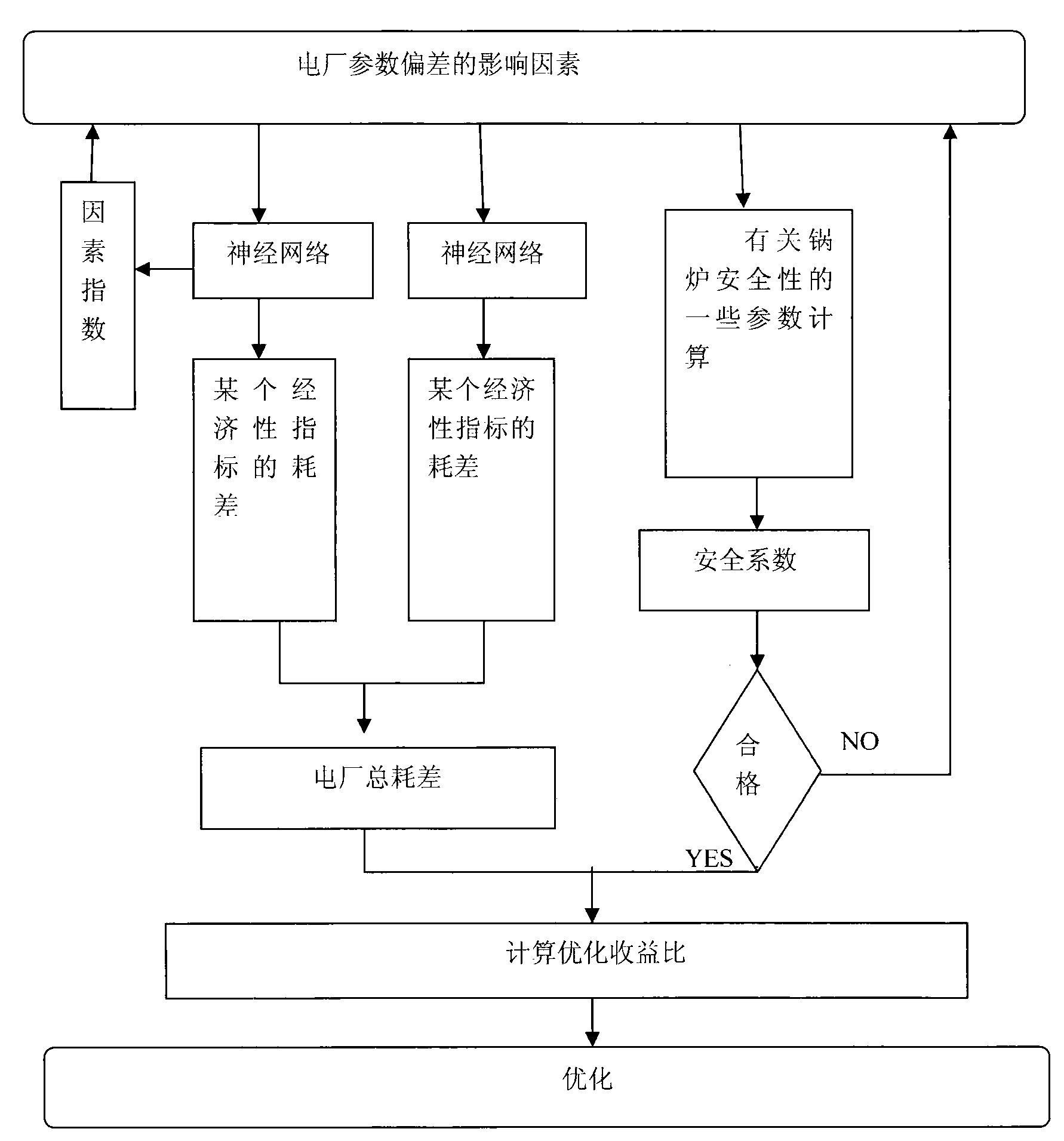

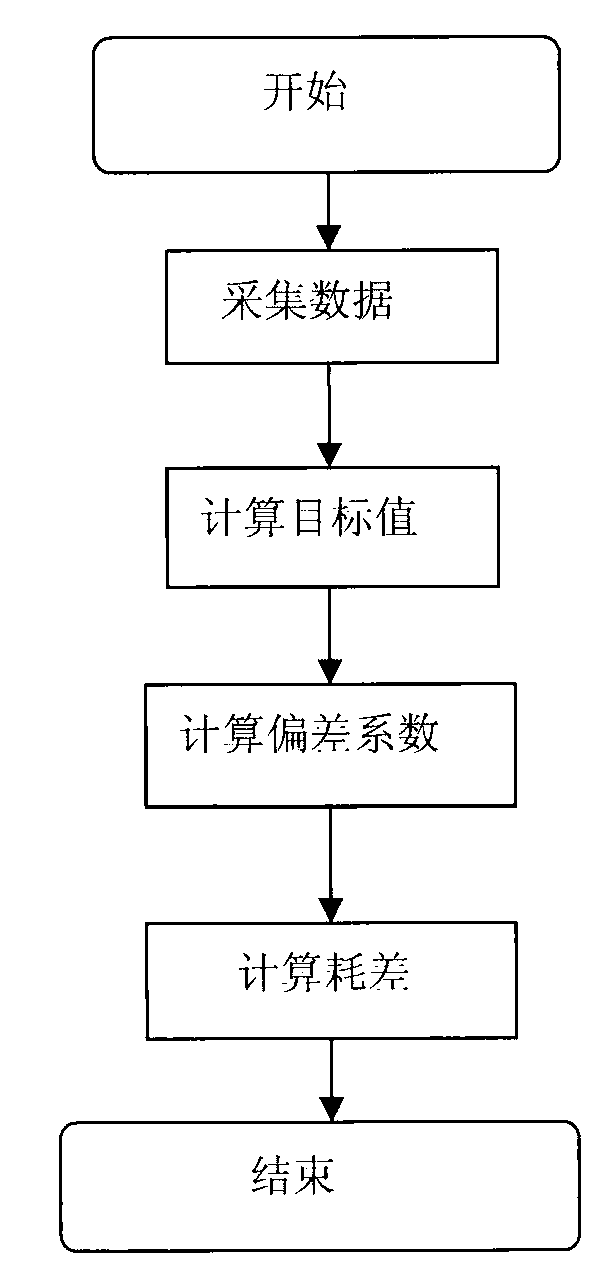

[0050] Such as figure 1 As shown, it is the flow chart of the research flow chart of the operation optimization consumption difference based on the boiler safety analysis. Taking the main steam temperature of a 600MW boiler as an example, the specific steps of the operation optimization consumption difference optimization method based on the boiler safety analysis are as follows:

[0051] Step 1. Carry out thermodynamic calculation for the boiler according to the boiler operating load, coal type and boiler operating conditions, and obtain the main steam under the main load (including 100% BMCR, 90% BMCR, 80% BMCR and 75% BMCR) working conditions The temperature target value is as follows:

[0052] the load

100%

90%

80%

75%

Target value (℃)

571

570

570

568

[0053] The rest of the load conditions are predicted by the neural network method, and the main steam temperature target values of the load conditions of 75%-80%, 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com