Direct-current submerged arc welding machine fusion depth increasing method and achieving circuit

A technology of submerged arc welding machine and depth of penetration, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., which can solve the problems of reduced welding efficiency and welding penetration that cannot meet the requirements, so as to reduce the number of welding layers and improve the welding efficiency. Speed, the effect of reducing the groove angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

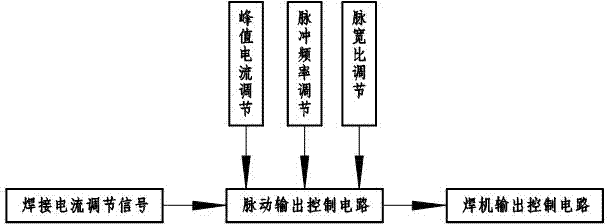

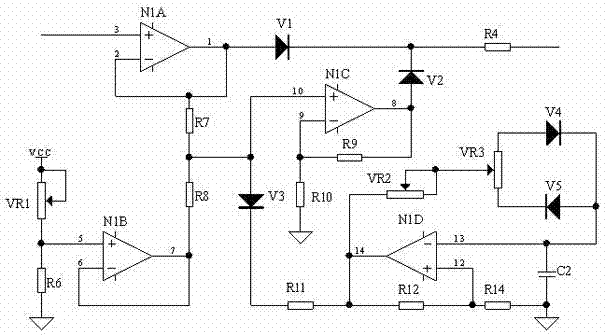

[0036] Such as figure 1 As shown, a method for enhancing the penetration depth of a DC submerged arc welding machine described in this implementation includes the following steps:

[0037] (1) Keep the effective value of the welding current unchanged, and adjust the peak-to-peak value of the pulse current to make it within the range of 300~500A;

[0038] (2) Keep the effective value of the welding current unchanged, and adjust the pulse width ratio of the pulse current so that it is within the range of 40% to 60%;

[0039] (3) Adjust the frequency of the pulse current so that it is in the range of 20~100Hz.

[0040] Taking the effective value of 600A as an example, Tables 1 to 9 show the influence of frequency on penetration when the current peak-to-peak value and pulse width ratio are constant.

[0041] Table 1 The effect of frequency on penetration when the peak-to-peak value is 400A and the pulse width ratio is 50%

[0042]

[0043] Table 1

[0044] Table 2 The e...

Embodiment 2

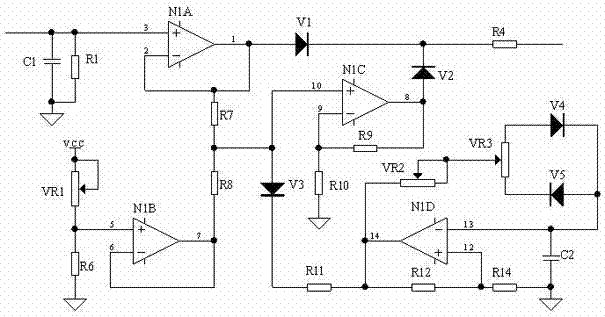

[0077] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1, the difference is that this embodiment also includes a resistor R1 and a capacitor C1, and the resistor R1 and capacitor C1 are connected in parallel between the positive input terminal of the operational amplifier N1A and the ground terminal, and the resistor R1 and capacitor C1 can reduce the interference in the input signal, filter the signal, and ensure a stable and reliable output signal.

Embodiment 3

[0079] Such as Figure 4 As shown, on the basis of Embodiment 2, this embodiment also includes a resistor R2, the resistor R2 is connected in series with the parallel resistor R1 and capacitor C1 and then connected between the positive input terminal of the operational amplifier N1A and the ground terminal. This increases the input impedance, prevents the abnormal voltage from the input signal from damaging the operational amplifier N1A, and increases the service life of the operational amplifier N1A.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap