Squeeze fabric dehydrator

A dehydrator, extrusion technology, used in textiles and papermaking, washing devices, household appliances, etc., can solve problems such as inability to dry clothes thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

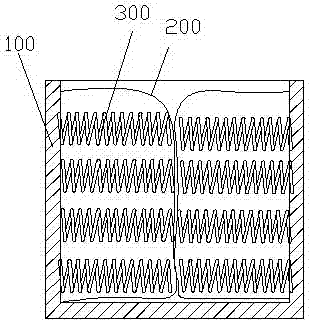

[0021] refer to figure 1 , in this embodiment, the extruding fabric dehydrator includes an inner tank 100, a driving motor and a washing machine shell, the inner tank 100 is arranged in the washing machine shell, and the driving motor is at the bottom of the washing machine shell and the washing machine shell The inner tank 100 is connected with power, and the peripheral wall of the inner tank 100 is covered with a plurality of airbag strips 200, and the airbag strips 200 communicate with an air pressure regulating device.

[0022] In the above extruded fabric dehydrator, the wall surface of the same airbag strip 200 includes at least two kinds of thickness specifications distributed at intervals, which makes the surface of the airbag strip 200 rougher and makes the inner tank 100 more effective in washing.

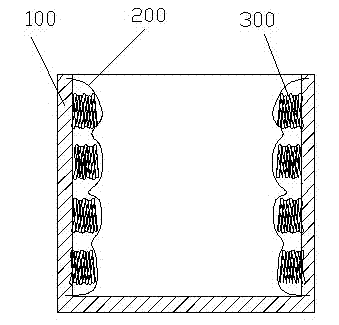

[0023] refer to figure 2 The airbag strip 200 is provided with at least two elastic members 300 as the support of the airbag strip 200, so that the airbag strip 200 has...

Embodiment 2

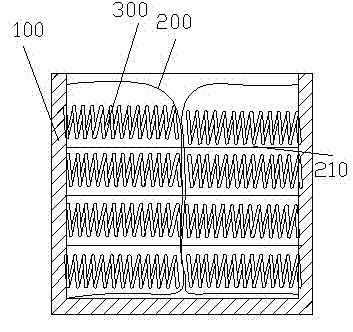

[0025] refer to image 3 with Figure 4 , in another preferred embodiment, a diaphragm 210 is provided between the elastic members in the airbag strip 200, and each elastic member 300 is independently contracted and expanded by the cooperation of the diaphragm 210 and the airbag strip 200. individual, the expansion and contraction states of the adjacent independently contracting and expanding individuals are opposite. The independently contracted and expanded individuals perform ups and downs under the action of the air pressure regulating device. This ups and downs movement is similar to kneading fabrics by hand, which improves the washing effect of the fabrics.

[0026] In summary, the principle of the extruded fabric dehydrator described above: in the first embodiment, the inner tank 100 shrinks the airbag strip 200 in the washing state, and in the second embodiment, the inner tank 100 shrinks in the washing state The individual of the airbag strip 200 is raised and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com