Stone-like aluminum alloy light grid component and construction method of decorative outer wall made of stone-like aluminum alloy light grid components

A construction method, aluminum alloy technology, applied in covering/lining, building, building structure, etc., can solve the problems of self-heaviness, endangering the safety of the overall structure, difficulty in meeting the construction progress, and project cost, etc., and achieve light weight and improved construction The progress, installation and construction methods are simple and easy to learn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

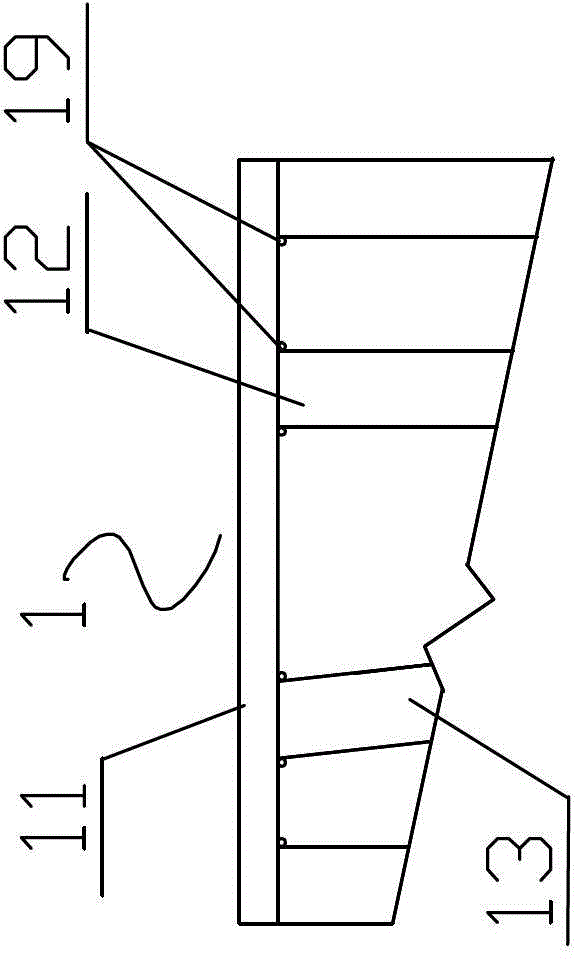

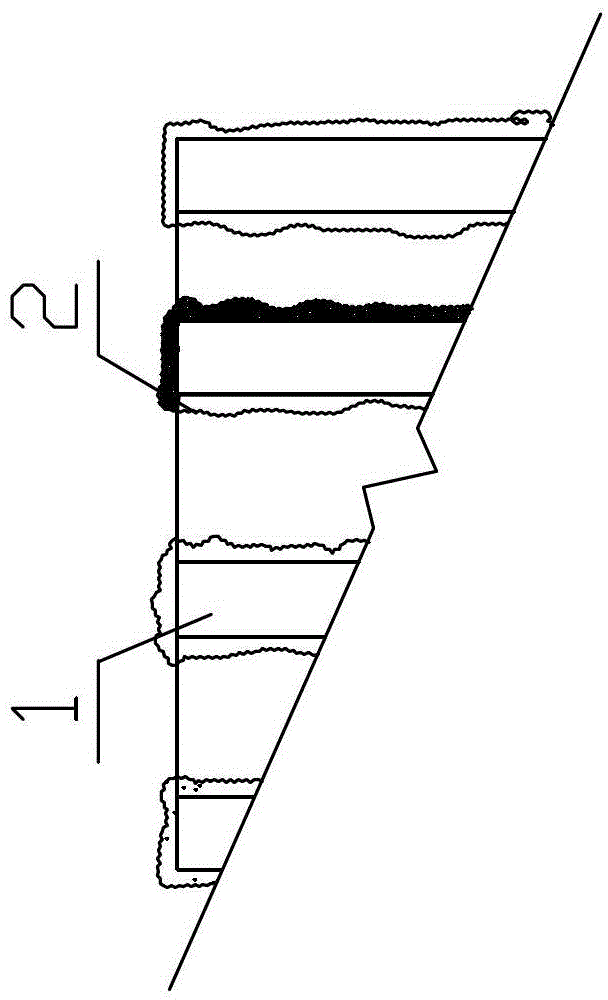

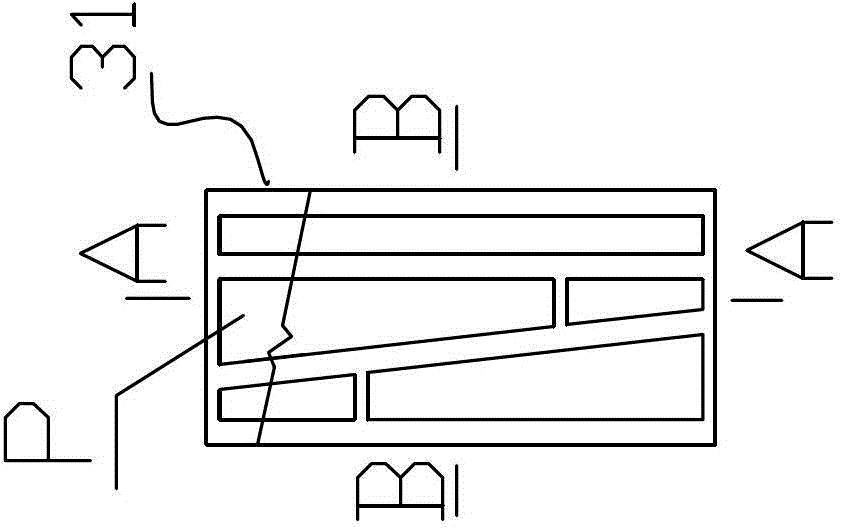

[0066] Embodiment 1: A stone-like aluminum alloy lightweight grid assembly, including a large stone-like aluminum alloy lightweight grid standard part 31 (see Figure 2-1 to Figure 2-3 ), small stone-like aluminum alloy lightweight grille standard part 32 (see Figure 3-1 to Figure 3-3 ) and special-shaped stone-like aluminum alloy lightweight grilles Ⅰ-Ⅷ (see Figure 4-1 to Figure 4-3 , Figure 5-1 to Figure 5-7 ); the large stone-like aluminum alloy lightweight grid standard part 31, the small stone-like aluminum alloy lightweight grid standard part 32 and various special-shaped stone-like aluminum alloy lightweight grids Ⅰ-Ⅷ (33-372) All are aluminum alloy lightweight grids 1 that are welded together by the horizontal aluminum alloy section 11, the vertical aluminum alloy section 12 and the special-shaped aluminum alloy section. Layer imitation stone paint - stone paint 2 (see Figure 1-1~Figure 1-2 ).

[0067] The special-shaped aluminum alloy profile section constituti...

Embodiment 2

[0070] Embodiment 2: A construction method for decorating an exterior wall surface with a stone-like aluminum alloy lightweight grid.

[0071] The method is to install the stone-imitation aluminum alloy lightweight grid assembly described in Embodiment 1 on the outer surface of the main body of the building, that is, to install the stone-imitation aluminum alloy lightweight grid assembly of different specifications manually from bottom to top. The way of stacking is placed; that is: the stone-like aluminum alloy lightweight grille components of different specifications are assembled in the form of dry-hanging structure; the tie parts 5 are respectively connected with the structural main body 4 and the stone-like aluminum alloy lightweight grille The components are connected and fixed, and at the same time combined into various appearance shapes; including the following specific steps:

[0072] A. Install the anchors: Before the construction of the main body of the building, on...

Embodiment 3

[0079] Embodiment 3 is a transformation of Embodiment 2 of the present invention, that is, the construction method of the above-mentioned stone-like aluminum alloy light grid of the present invention to decorate the exterior wall is also applicable to the exterior surface of the main body of the building where the glass curtain wall has already been installed. Carry out external wall surface installation, its method step is basically the same as embodiment two, and difference is:

[0080] 1. In the specific steps of A. Install the tie piece: before installing the glass of the glass curtain wall, one end of the tie piece 5 of the aluminum square keel 6 used to install the stone-like aluminum alloy lightweight grid is closed on the curtain wall glass inside the seam (see Figure 6-1 ), the tie 5 also includes a T-shaped code 51 and an L-shaped code 52, which respectively have a bar-shaped groove 511, 521 for installation (see Figure 8-1 to Figure 8-6 ).

[0081] 2. In the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com