Stone-like aluminum alloy light grating and manufacturing method thereof

A technology of aluminum alloy and aluminum alloy profiles, which is applied in the direction of building components, covering/lining, walls, etc., can solve the problems of self-heaviness, endangering the safety of the overall structure, and high transportation costs, so as to achieve simple and easy installation methods, improve construction progress, and make The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

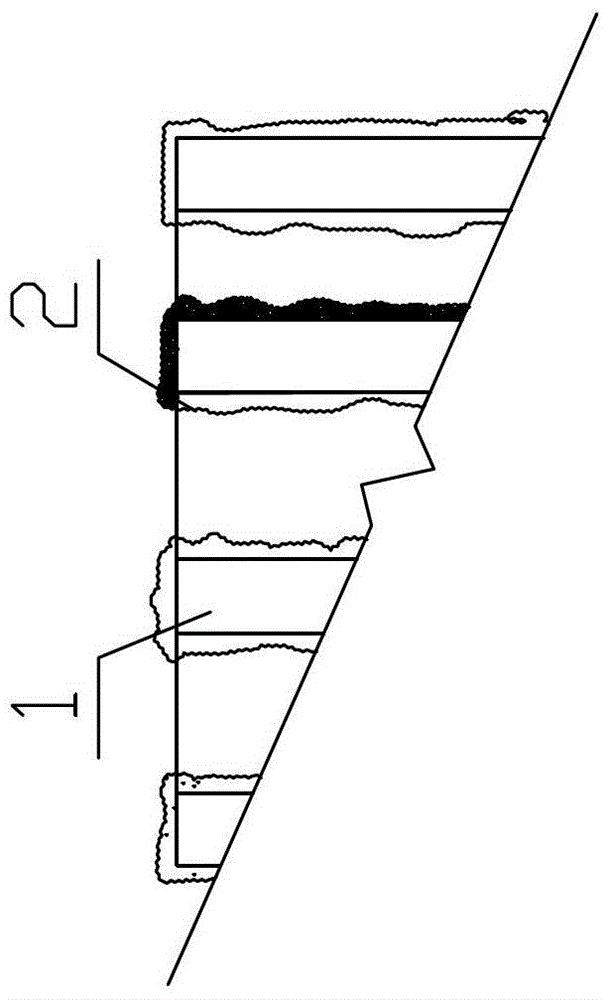

[0043] A stone-like aluminum alloy lightweight grille; an aluminum alloy lightweight grille 1 that is welded together by aluminum alloy sections, and a layer of stone-like paint is coated on the surface of the aluminum alloy lightweight grille 1, namely Stone Paint 2 (see Figure 1-1~Figure 1-2 ).

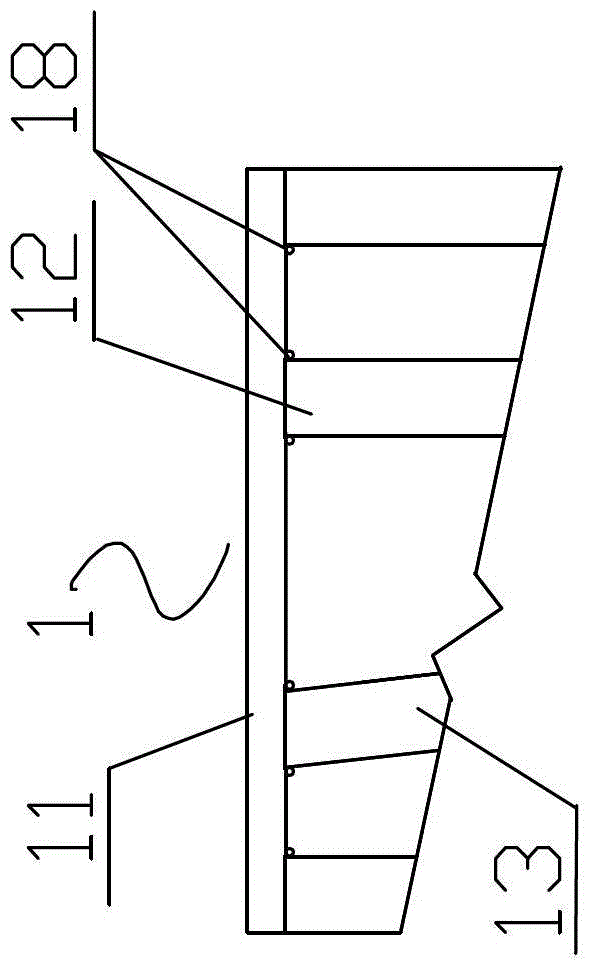

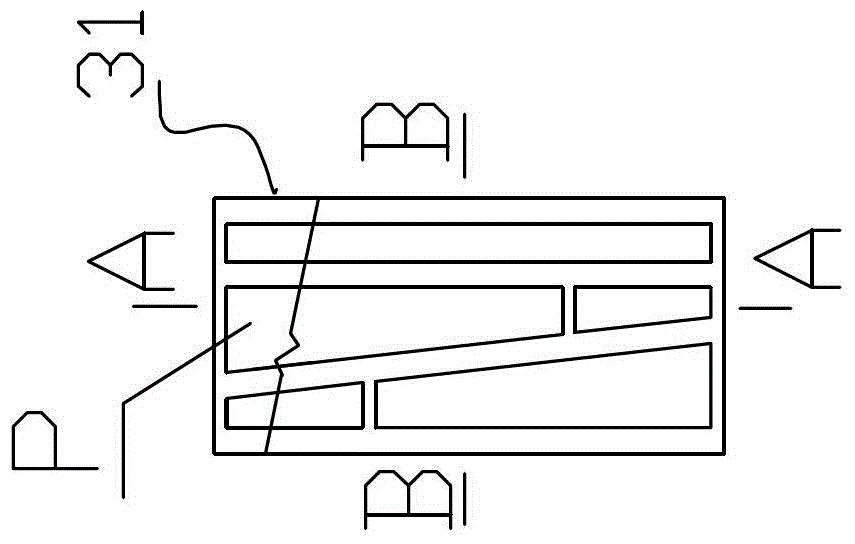

[0044] Such as Figure 2-1 to Figure 5-7 , the aluminum alloy lightweight grille 1 is composed of a horizontal aluminum alloy profile section 11, a vertical aluminum alloy profile section 12, and special-shaped aluminum alloy profile sections including oblique straight lines 13 in planar shape, including large aluminum alloy lightweight Grille standard (see Figure 2-1 to Figure 2-3 ); small aluminum alloy lightweight grille standard parts (see Figure 3-1 to Figure 3-3 ) and special-shaped aluminum alloy lightweight grille (see Figure 4-1 to Figure 5-7 ).

[0045] The special-shaped aluminum alloy profile section constituting the aluminum alloy lightweight grid 1 includes a p...

Embodiment 2

[0049] A method for manufacturing a stone-like aluminum alloy lightweight grid, the method comprising the following steps:

[0050] A. Making aluminum alloy profile sections: In the component factory, the aluminum alloy profiles are processed and formed into horizontal aluminum alloy profile sections 11, vertical aluminum alloy profile sections 12, and plane shapes including oblique straight lines 13, curves 14, squares 15, Round 16, oval 17 or other polygonal special-shaped aluminum alloy section;

[0051] B. Making aluminum alloy lightweight grids: According to various large stone-like aluminum alloy lightweight grid standard parts, small stone-like aluminum alloy lightweight grid standard parts and special-shaped stone-like aluminum alloy lightweight grids provided in the design drawings The spatial coordinates and shape of the grid and the actual size of the construction site, the aluminum alloy profile sections are welded together in the component factory to make large al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com