Pressure reducing valve

A pressure-reducing valve and valve stem technology, applied in the field of pressure-reducing valves, can solve problems such as the narrow application range of pressure-reducing valves, and achieve the effects of enhancing turbulent effects, intensifying friction and collision, and facilitating maintenance and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

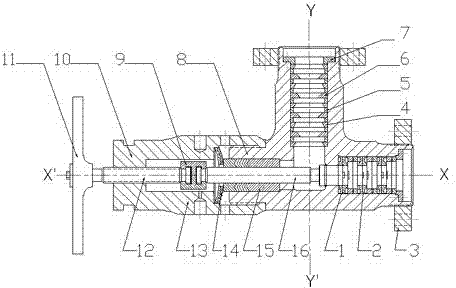

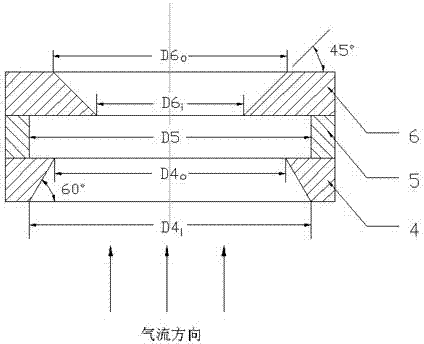

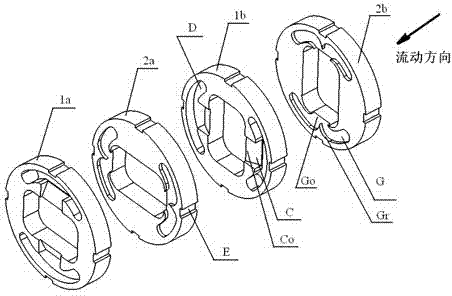

[0007] like figure 1 As shown, the present invention is a pressure reducing valve, including a valve body composed of a valve body 8 and a rotary valve cover 10, a compression packing sealing pair 15, a disc spring group 14 for sealing, and a rectangular hole guide plate 1 and the rectangular hole diverter plate 2 are superimposed to form a first-stage step-down, the diffuser ring 4, the distance ring 5 and the speed-increasing ring 6 are superimposed to form a second-stage step-down, and the gland 7 is pressed to fix the first-stage and second-stage The pressure-reducing group component, the valve stem is composed of an upper valve stem 12 and a lower valve stem 16, the middle of the two parts of the valve stem is connected by a split joint 9, and the upper valve stem 12 is rotated and lifted by the driving turntable 11.

[0008] like figure 1 As shown, the rectangular hole diverter plate 1 and the rectangular hole diverter plate 2 are formed into a pair of rectangular hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com