Rotary armature support mechanism for magnetic release

A technology of rotating armature and magnetic tripping, which is applied in the direction of protection switch operation/release mechanism, magnetic/electric field switch, protection switch parts, etc., which can solve the problems of assembly trouble and increased cost of magnetic tripper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

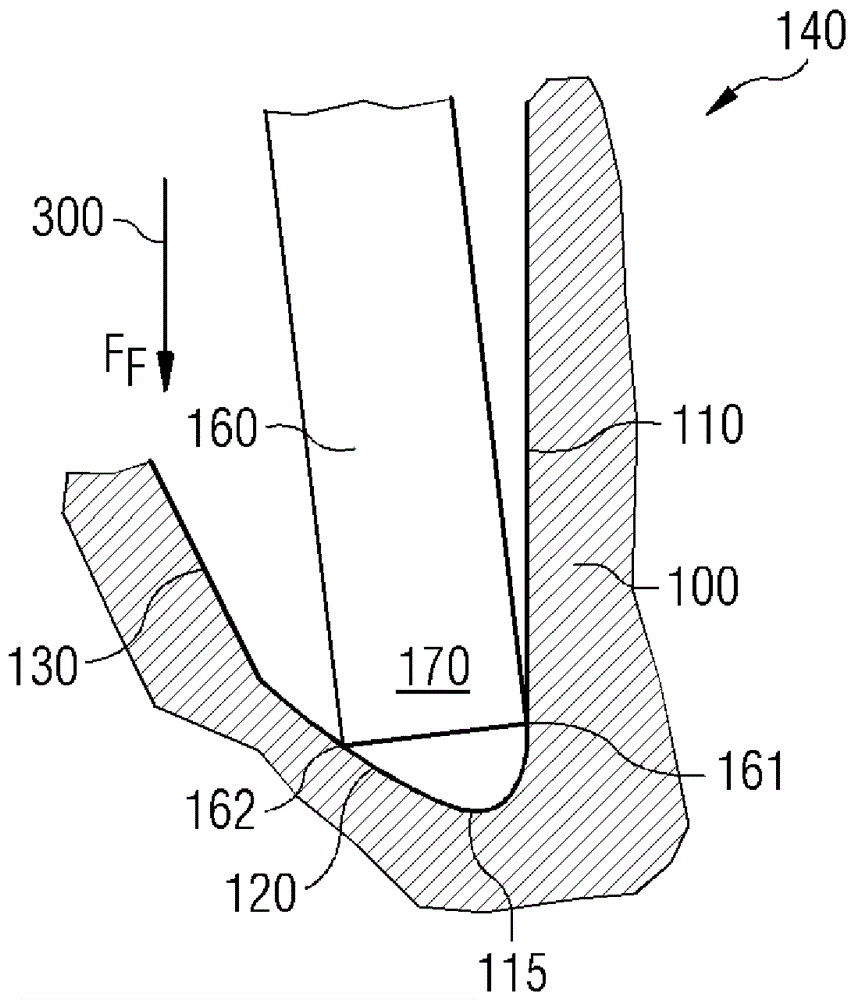

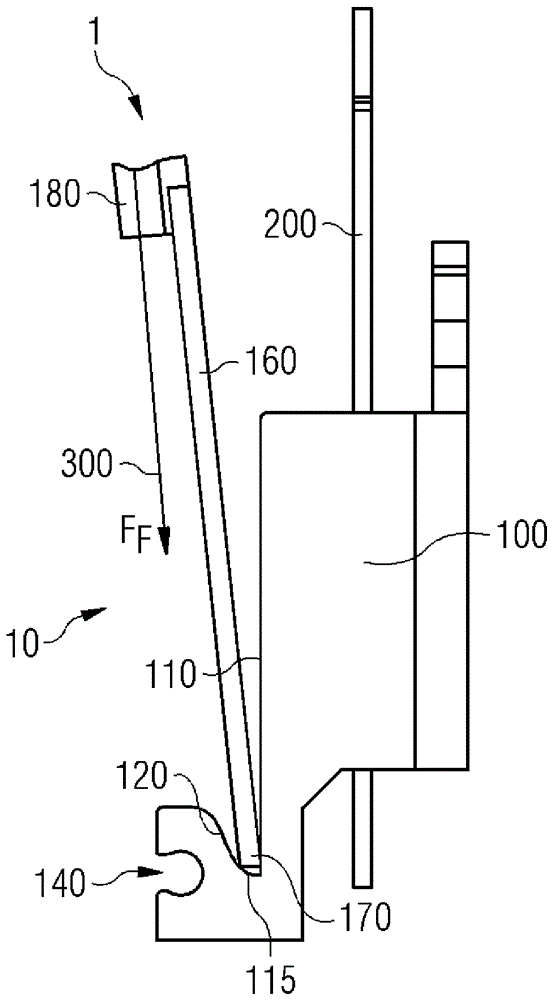

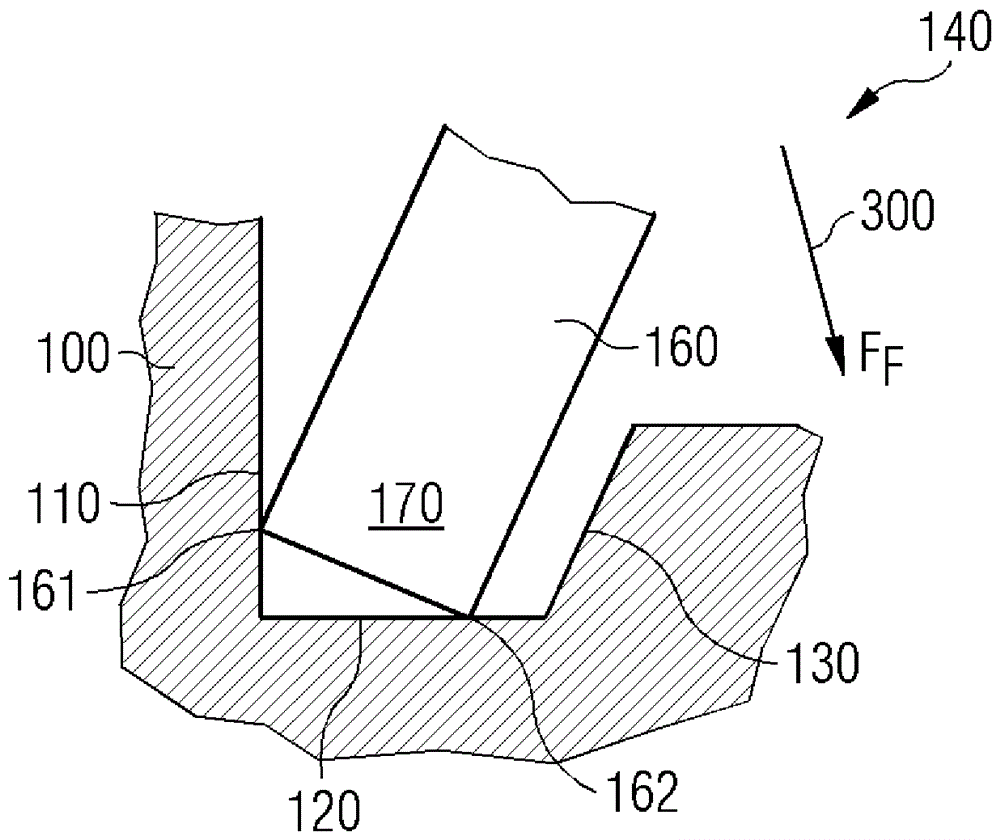

[0043] figure 1 with figure 2 A rotary armature bearing 140 is shown, as it is known from the prior art. The stop surface 110 , the support surface 120 and the contact surface 130 are formed as part of the magnetic yoke 100 . In particular, the stop surface 110 and the support surface 120 are arranged at an angle of 90° to one another. A first end 170 of the swivel armature 160 is inserted into the swivel armature bearing 140 . The spring force 300 acts on the second end 180 (not shown) of the rotating armature 160 . Swivel armature 160 is pressed into swivel armature bearing 140 by at least part of spring force 300 . The swivel armature 160 rests on one side against the contact surface 130 of the swivel armature bearing 140 , wherein the bearing edge 162 is arranged on the bearing surface 120 . However, the pivoting edge 161 is not arranged on the stop surface 110 . The spring force 300 also does not affect the movement of the rotating armature 160 so that the pivoting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com