Method for regulating spacing during laser machining process

A technology of laser processing and laser processing head, which is applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of poor measurement resolution of measurement time intervals, and achieve the effect of improving dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

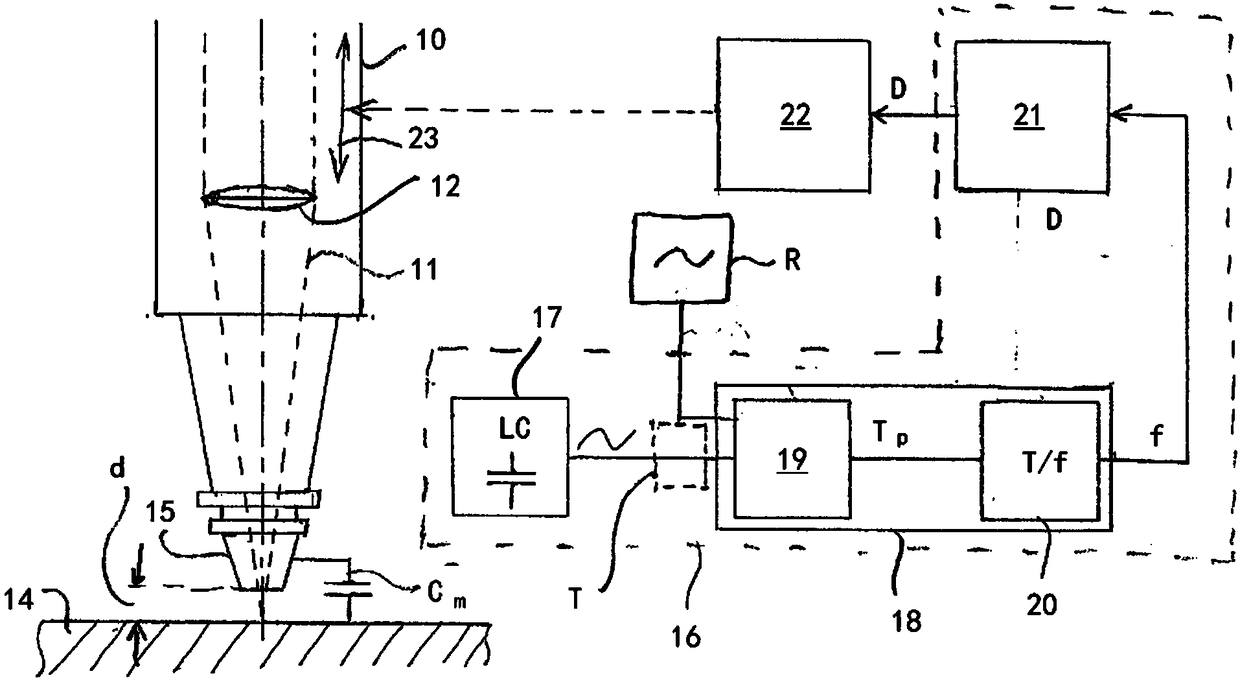

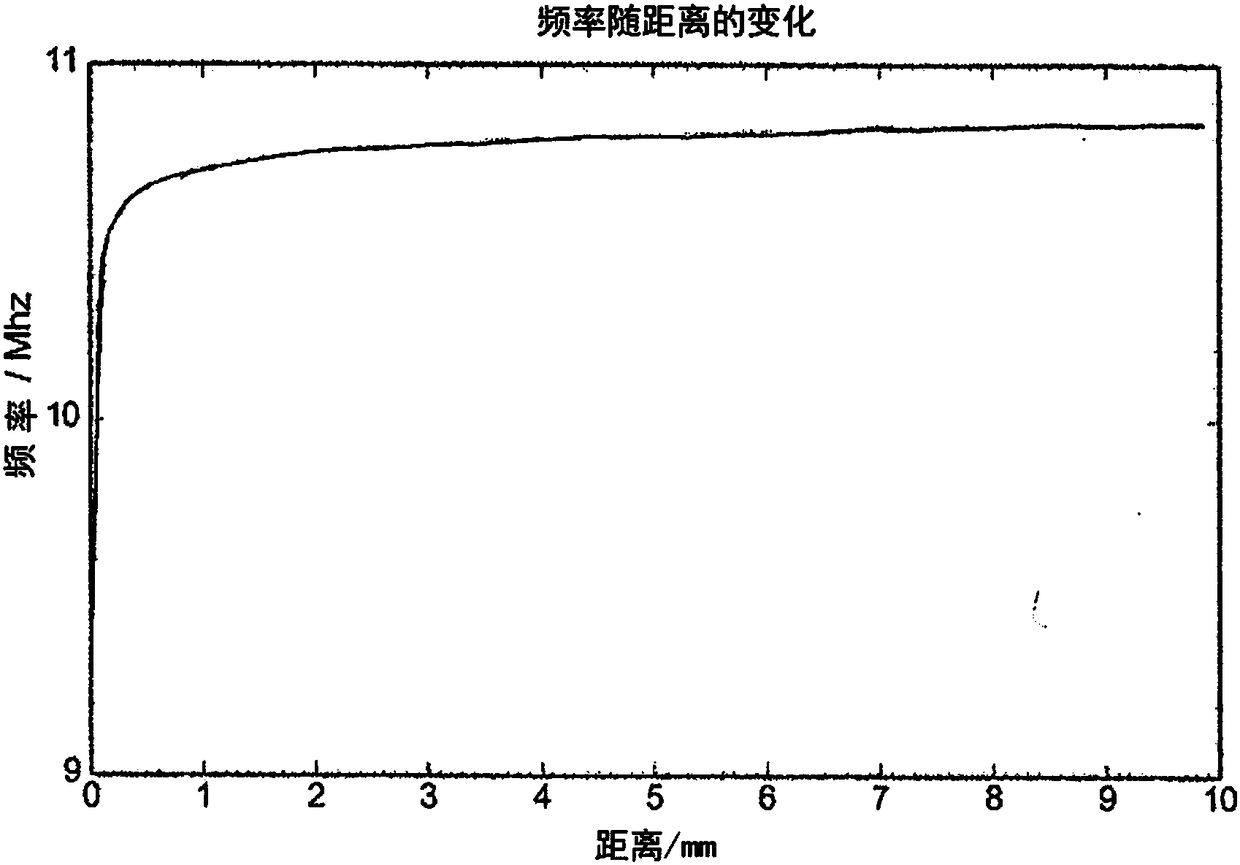

[0017] figure 1 A laser processing head 10 of a laser processing device is shown schematically, through which a working laser beam 11 is focused onto a workpiece 14 by means of a focusing lens 12 . In order to measure the distance d between the nozzle tip 15 of the laser processing head 10 and the workpiece 14, the capacitance Cm between the nozzle tip 15 and the workpiece 14 is connected to the resonant circuit, in particular the LC resonant circuit 17 of the distance sensor 16 . The LC resonant circuit used in the exemplary embodiment with a fundamental frequency in the range of approximately 10 MHz oscillates in a suitable manner. The basic frequency of the LC resonant circuit can also be selected from the range of 9 MHz to 11 MHz or preferably from the range of 9.5 MHz to 10.5 MHz. The output signal of the LC-oscillating circuit 17 , which is related to the capacitance Cm between the workpiece 14 and the nozzle tip 15 , is supplied to a circuit 18 which determines the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com