Die machining gas turbine special-shaped balancing weight with radian of R430 and method for machining special-shaped balancing weight with die

A gas turbine and counterweight technology, which is applied in manufacturing tools, metal processing equipment, mechanical equipment, etc., can solve the problems of irregular counterweight size errors, waste products, unreasonable tooling design, etc., to avoid processing errors and pass rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

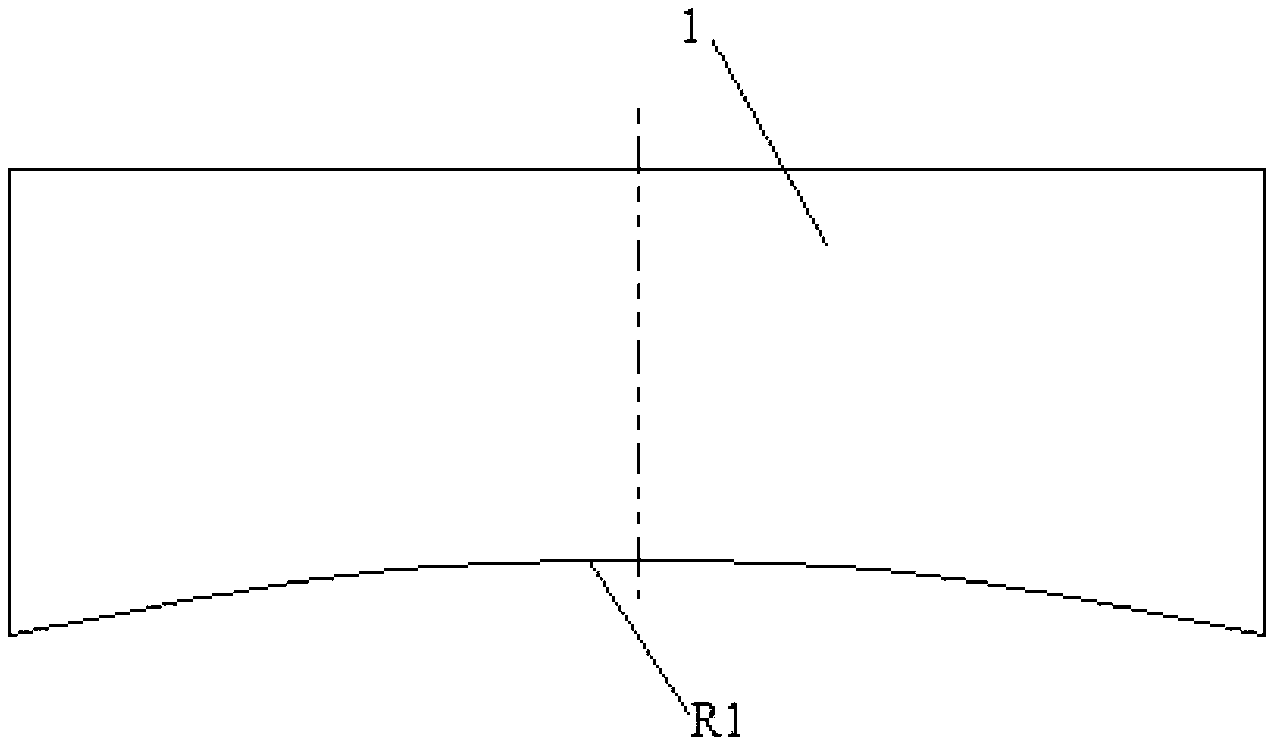

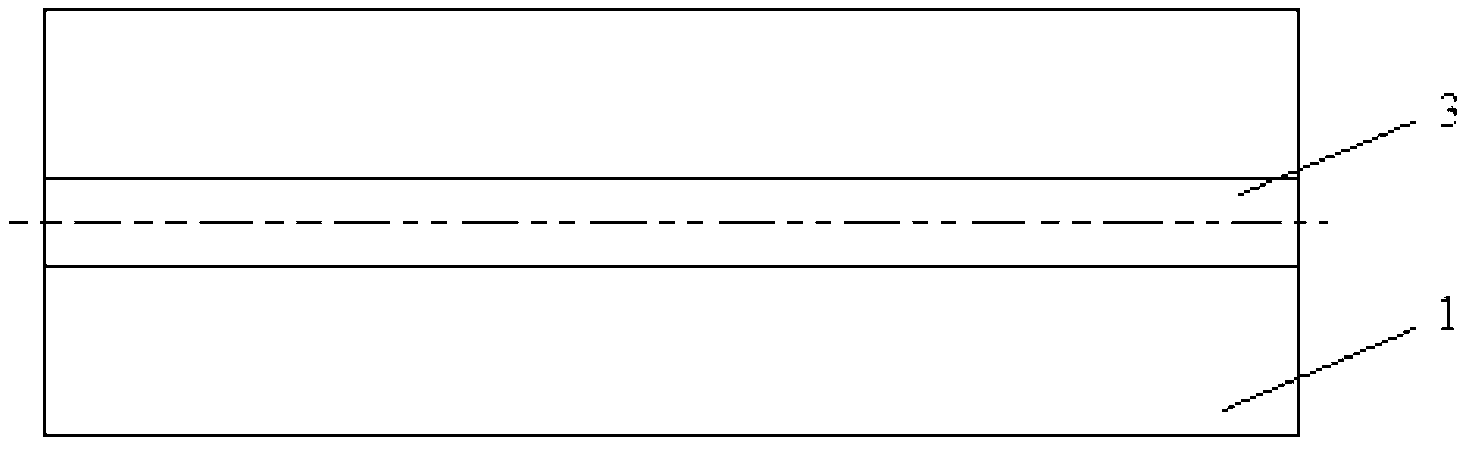

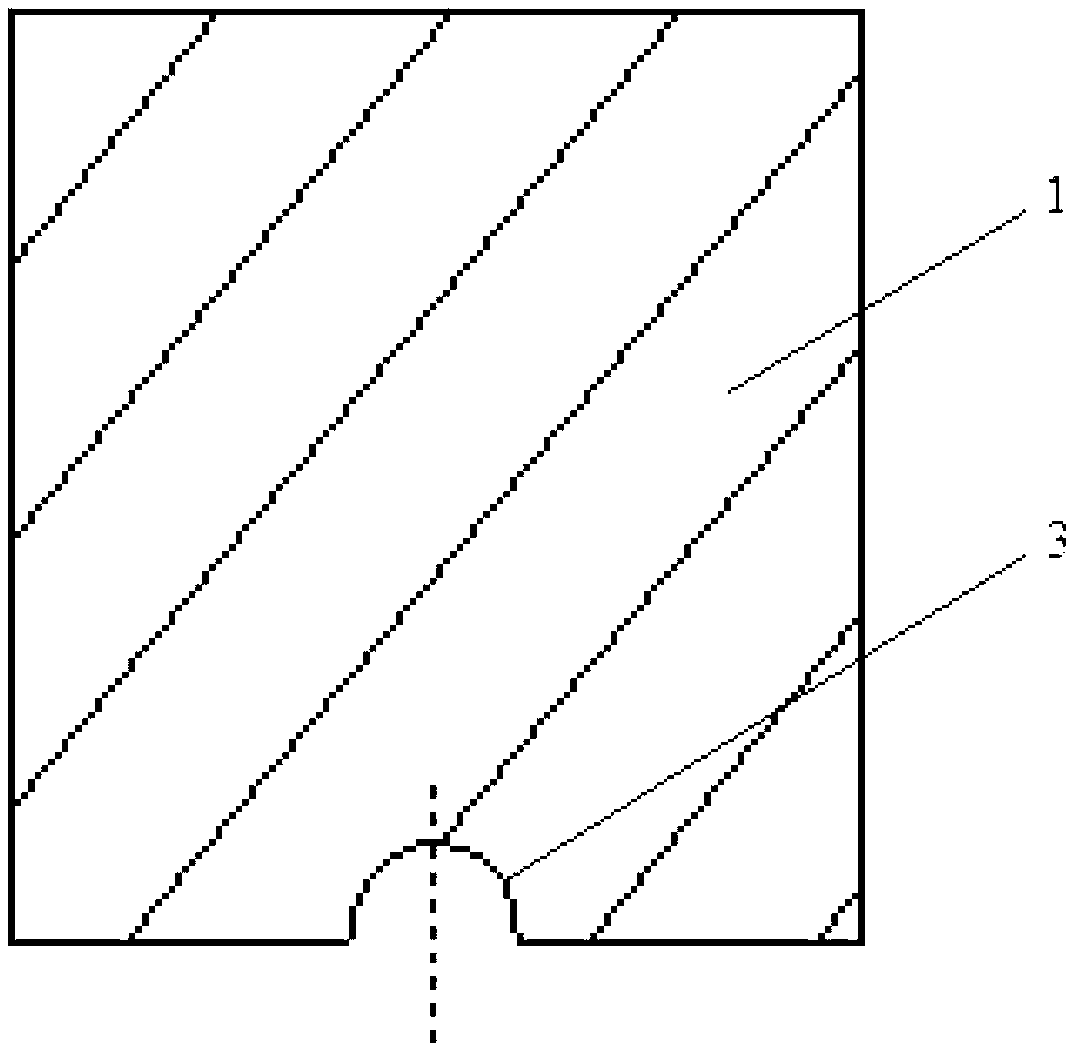

[0017] Embodiment 1: A mold for processing a special-shaped counterweight block with a gas turbine radian of R430 in this embodiment is composed of a die 1 and a punch 2, and the radian of the die 1 is R 1 For R431, punch 2 radian R 2 It is R429; said die 1 has a groove 3 along the length direction on the arc surface, and said punch 2 has a groove 4 on the arc surface along the length direction corresponding to the groove 3, so The radius R of the groove 3 3 and the radius R of the groove 4 4 are equal, and groove 3 and groove 4 cooperate with each other.

[0018] In this embodiment, a mold for processing a special-shaped counterweight with a gas turbine radian of R430 sets the radian of the die as R431, and sets the radian of the punch as R429, so that the mating of the die and the punch increases compared with the existing method. The anti-processing springback allowance of 1.5, just makes the special-shaped counterweight product meet the size requirements after springbac...

specific Embodiment approach 2

[0019] Specific embodiment two: a kind of processing gas turbine radian of the present embodiment is the method for the mold processing R430 special-shaped counterweight of R430 special-shaped counterweight, it is characterized in that the method is carried out according to the following steps:

[0020] 1. Turn the feeder into a cylindrical bar, and the radius of the cylindrical bar is R 5 , and then heated to a temperature of 290-350°C with an oxyacetylene flame;

[0021] 2. Put the heated bar in step 1 into the groove 4 of the mold, match the groove 3 and the groove (4) under the die 1, and then use the vise to pressurize the die 1 and the punch 2 There is no gap, and the pressure is maintained for 5 minutes to 10 minutes to obtain a special-shaped counterweight with a radian of R430, wherein the radius R of the groove 3 3 and the radius R of the groove 4 4 equal, where the radius R of the cylindrical rod 5 and the radius R of groove 3 3 and the radius R of the groove 4 ...

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 2 in that: In Step 1, use an oxyacetylene flame to heat to a temperature of 310-330° C., and other steps and parameters are the same as Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com