Liquid spray head and manufacturing method thereof

A technology of liquid nozzles and manufacturing methods, which is applied in printing and other directions, and can solve problems such as high manufacturing costs, low yield of liquid nozzles, and low printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Following will describe the present invention in detail by embodiment:

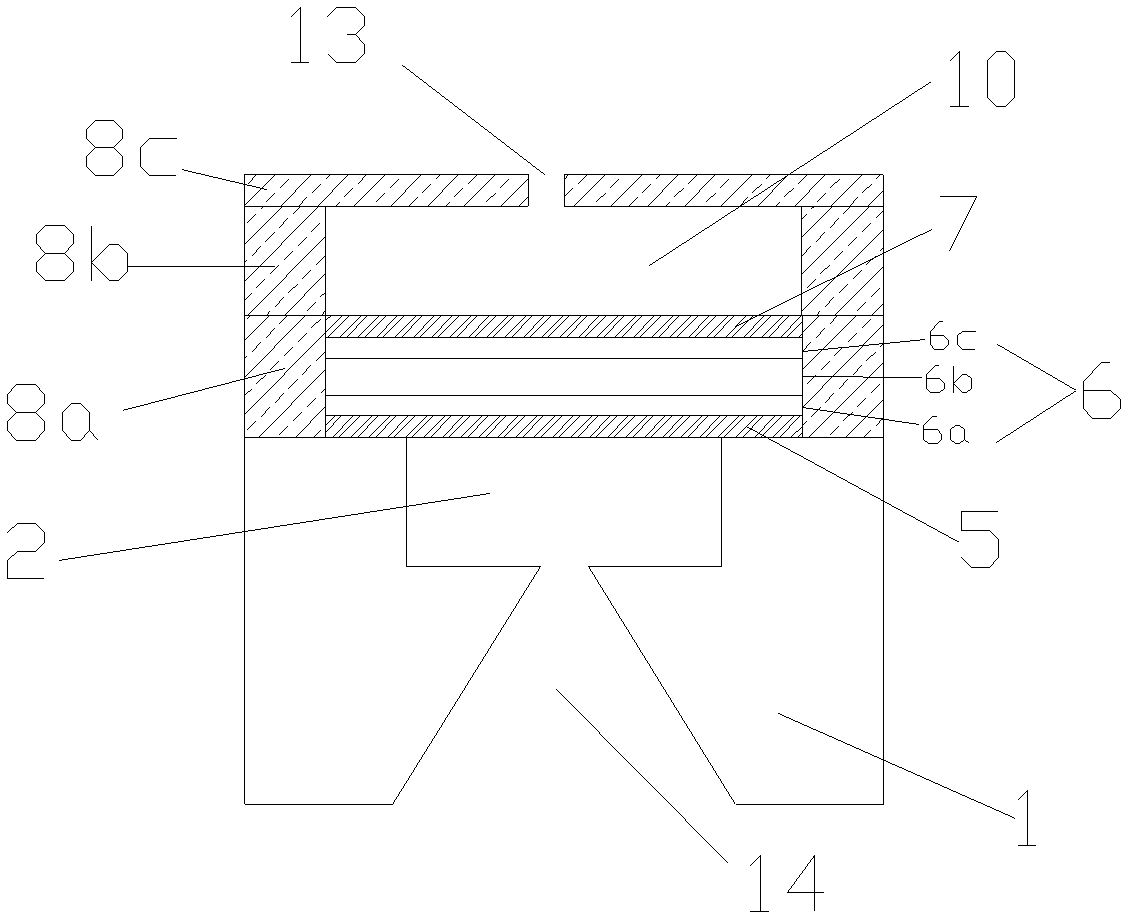

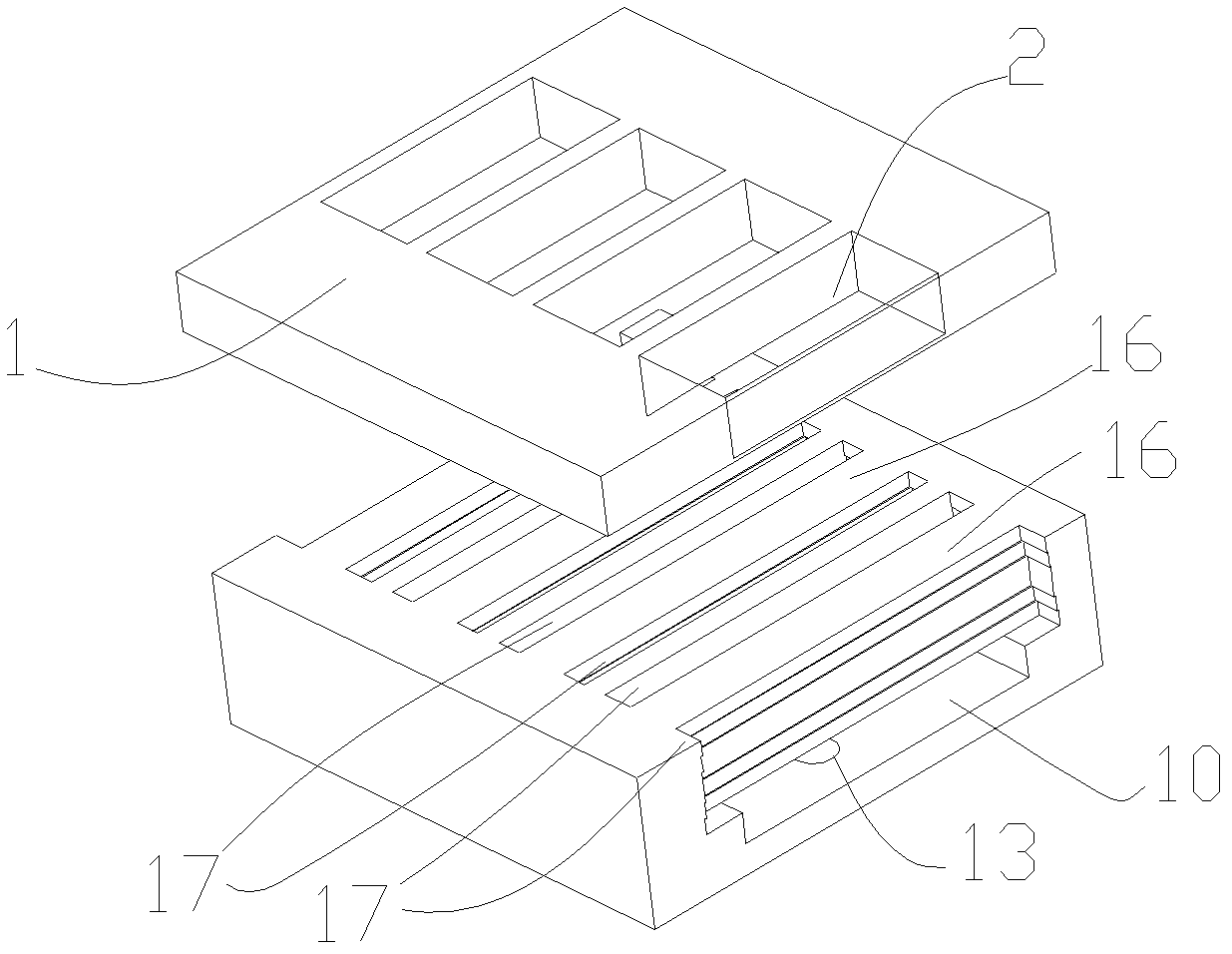

[0046] figure 1 and figure 2They are respectively a sectional view and a perspective view of a liquid ejection head according to an embodiment of the present invention. As shown in the figure, a liquid ejection head includes: a silicon substrate 1; several polymer film layers arranged on the surface of the silicon substrate, and a piezoelectric element thin film layer 6a / 6b / 6c, nozzle orifice film layer 8c; the part of the several polymer film layers at the position of the liquid chamber, that is, the liquid chamber polymer film layer 8a / 8b forms the liquid chamber 10, the piezoelectric element 6 and the The nozzle hole 13 is formed at the part of the number of polymer film layers at the position of the nozzle hole 13; the piezoelectric element 6 is formed by the lower electrode 6a, the piezoelectric layer 6b and the lower electrode 6c formed by the piezoelectric element film layer, and the pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com