Automotive steering tie rod

A steering tie rod, automobile technology, applied in the direction of steering tie rod, steering mechanism, vehicle parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

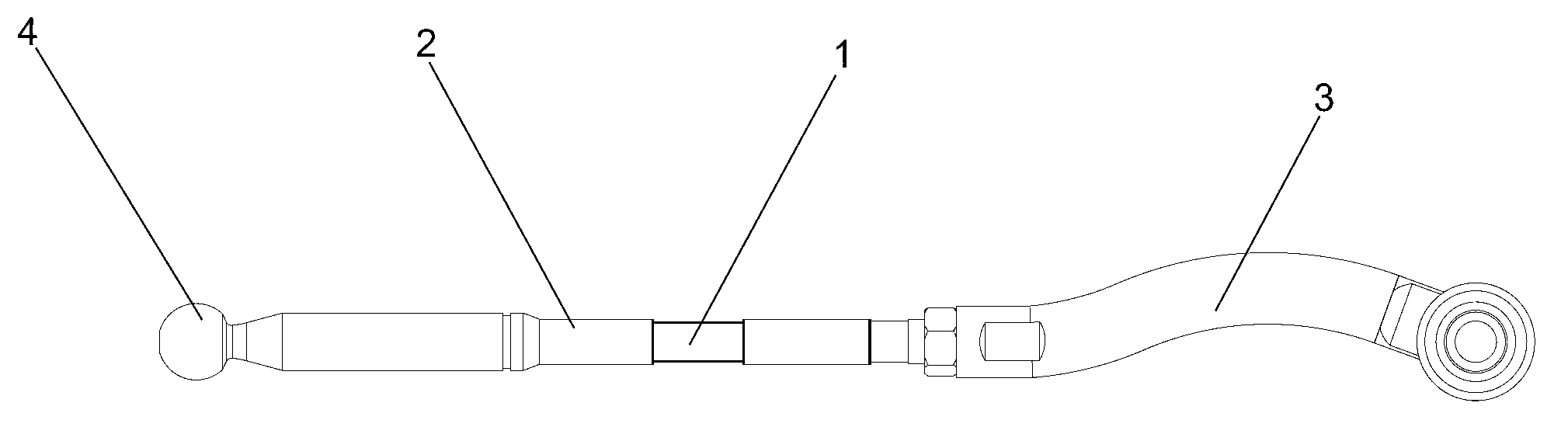

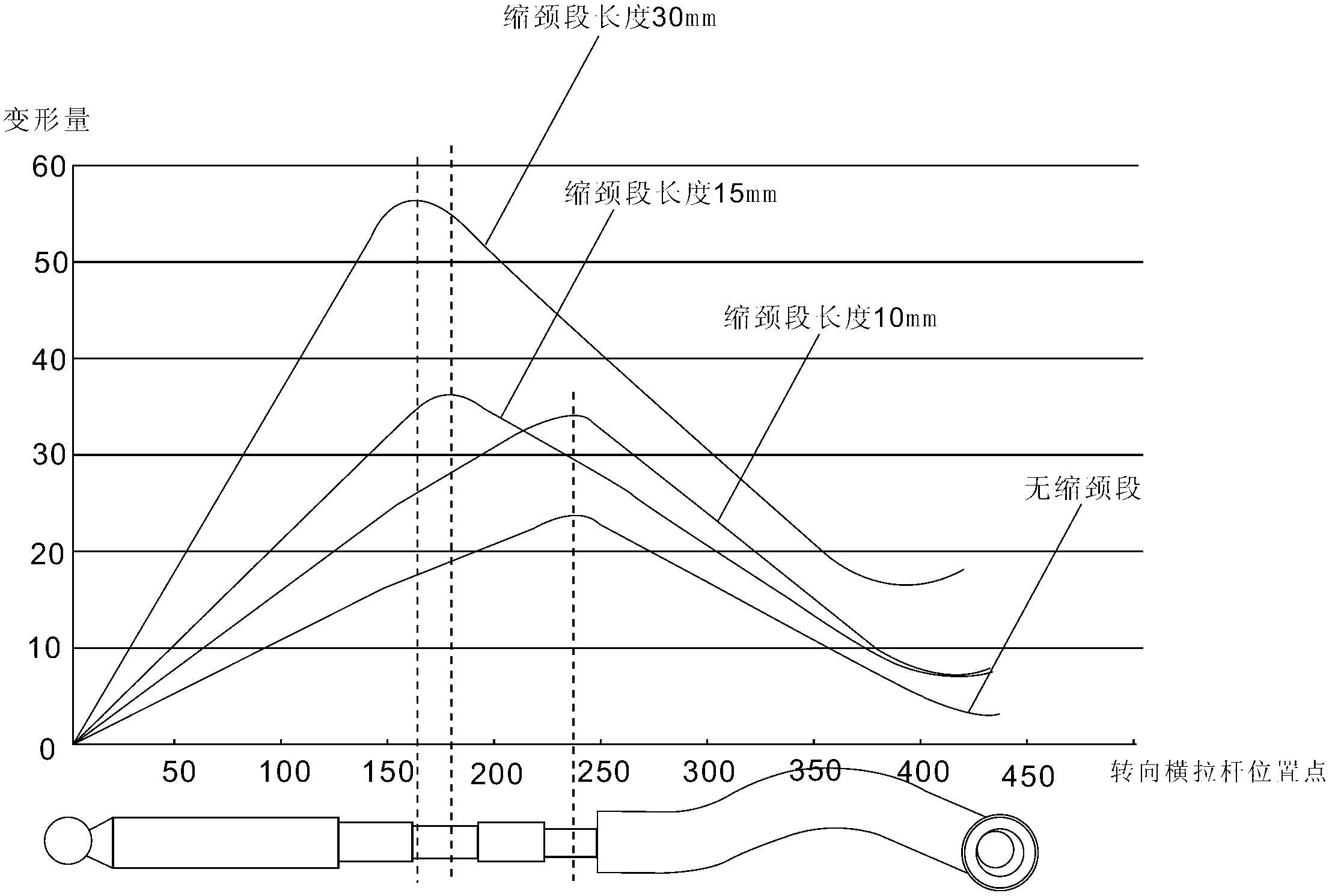

[0016] Such as figure 1 As shown, an automobile steering tie rod includes a straight rod body 2 and a joint rod 3, one end of the straight rod body 2 is provided with an external thread, and one end of the joint rod 3 is provided with an internal thread, and the straight rod body 2 and the joint rod 3 are connected into one body through threads The other end of the straight rod body 2 is integrally provided with a ball head 4, which is connected with the steering rack of the steering arm, and the other end of the joint rod 3 is hinged with the wheel steering knuckle. The total length of the straight rod body 2 from the ball head 4 to the threaded end surface is 224 mm. The straight rod body 2 includes three parts, the inner section, the middle section and the outer section, which are connected in sequence. There are steps between adjacent sections. The ball head 4 is located on the inner section, and the diameter of the inner section is 13mm. The diameter is 19mm, an...

Embodiment 2

[0019] An automobile steering tie rod, the length of the necking section 1 is 30 mm, the diameter of the necking section 1 is 12.2 mm, the ratio of the length of the necking section 1 to the total length of the straight rod body 2 is about 0.13, and the center of the necking section 1 to The ratio of the distance from the center of the necking section 1 of the straight rod body 2 to the center of the ball head of the straight rod body 2 and the length of the straight rod body 2 is about 0.67. The ratio of mid-section diameters of 2 is about 0.87. All the other are with embodiment 1.

[0020] When the tie rod in this embodiment is irreversibly bent, the bending part is also in the necking section 1. Compared with the prototype steering tie rod without the necking section 1, the pressure resistance is lower, but it is still under normal conditions. The steering function can be performed normally.

Embodiment 3

[0022] An automobile steering tie rod, the length of the necking section 1 is 20 mm, the diameter of the necking section 1 is 12 mm, the ratio of the length of the necking section 1 to the total length of the straight rod body 2 is about 0.09, and the center of the necking section 1 to the straight The ratio of the distance from the center of the necking section 1 of the rod body 2 to the center of the ball head of the straight rod body 2 to the length of the straight rod body 2 is about 0.70. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com