Non-destructive inspection circumferential position correction method for thread hole belt of nuclear reactor pressure vessel

A circumferential position and pressure vessel technology, applied in nuclear reactor monitoring, reactors, nuclear engineering, etc., can solve problems affecting scanning accuracy and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

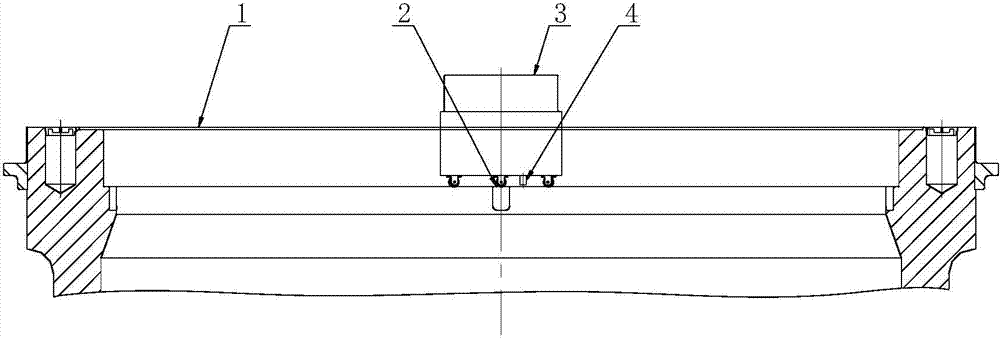

[0026] like figure 1 As shown, the inspection trolley performs scanning inspection on the threaded hole belt of the nuclear reactor pressure vessel, and moves along the circumference of the reactor pressure vessel.

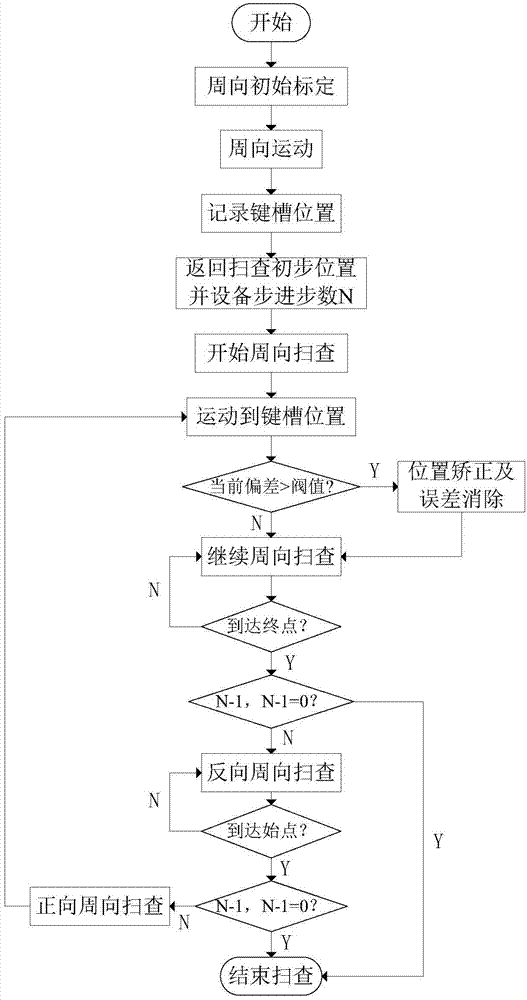

[0027] The method for correcting the circumferential position of the threaded hole belt of the nuclear reactor pressure vessel according to the present invention includes the following steps:

[0028] Step 1) Use the 4 keyways of the supporting steps on the nuclear reactor pressure vessel as a position reference.

[0029] Since the inspection trolley 3 performs automatic ultrasonic inspection on the threaded hole strip of the pressure vessel, the scanning method is circumferential movement, and the radial and axial steps of the two scanning arms are simultaneously stepped. At the same time, the form of circumferential motion of inspectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com