Lubricating oil of dual-fuel engine and preparation method of lubricating oil

A dual-fuel engine, lubricating oil technology, applied in the direction of lubricating composition, etc., can solve the problems of accelerated engine wear and aging of lubricating oil, wear of intake valve, exhaust valve and valve seat, large evaporative loss of lubricating oil, etc. Reduced sludge and coke formation, extended oil drain intervals, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

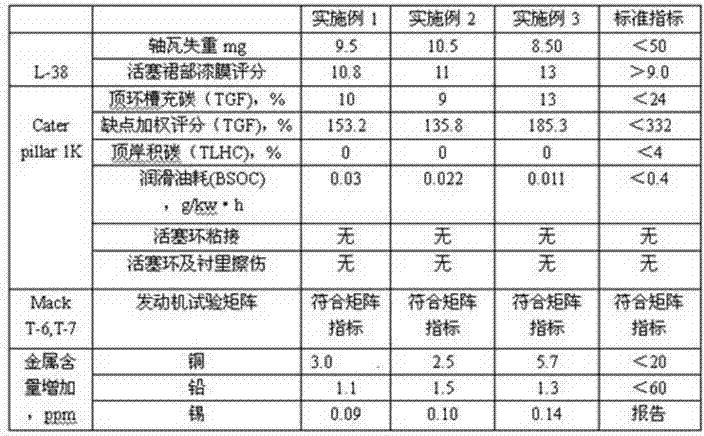

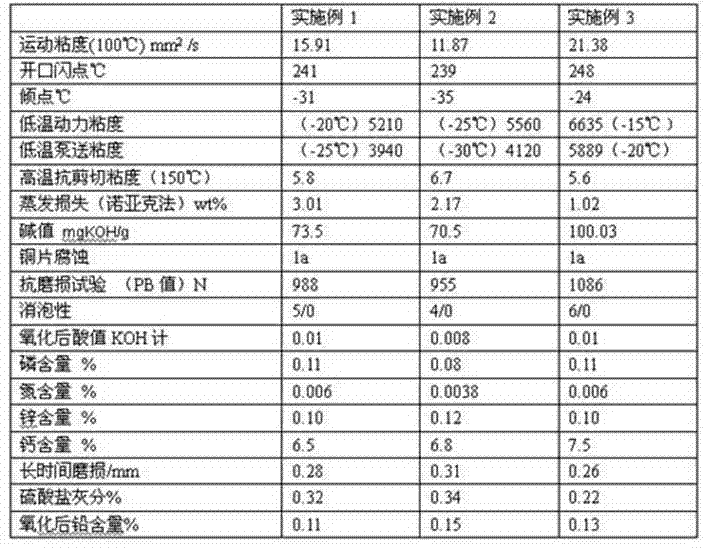

Examples

Embodiment 1

[0037] Example 1 15W / 40-SG / CF general internal combustion engine lubricating oil

[0038] Weigh raw materials according to the following weight percentages:

[0039] Class II hydrogenated base oil 500SN 60.998%;

[0040] Polyalphaolefins with molecular weight > 8000 15%;

[0041] High base number synthetic calcium sulfonate 15%;

[0042] Thionium butoctyl zinc salt 2%;

[0043] Ethylene-propylene copolymer with molecular weight > 13000 5%;

[0044] Dialkylmolybdenum dithiophosphate 2%;

[0045] Methyl silicone oil 0.0002%;

[0046] The total base number of the synthetic calcium sulfonate with high base value is 500, the calcium content is 30m%, and the sulfur content is 1.2m%; m %, the sulfur content is 7.5 m %; the molybdenum content of the molybdenum dialkyldithiophosphate is 14.5 m %, the sulfur content is 6.5 m %, the phosphorus content is 3.3 m %, and the nitrogen content is 0.3 m %;

[0047]Mix the second-class hydrogenated base oil 500SN, polyα-olefin and high al...

Embodiment 2

[0050] Example 2 10W / 30-SJ / CH general internal combustion engine lubricating oil

[0051] Weigh raw materials according to the following weight percentages:

[0052] Class II hydrogenated base oil 500N 62.4999%;

[0053] Polyalphaolefin with a molecular weight of 6300 15%;

[0054] High base number synthetic calcium sulfonate 20%;

[0055] Thionium butoctyl zinc salt 2.5%;

[0056] Ethylene-propylene copolymer with a molecular weight of 14500 1%;

[0057] Dialkylmolybdenum dithiophosphate 1.5%;

[0058] Methyl silicone oil 0.0001%;

[0059] The total base number of the synthetic calcium sulfonate with high base value is 470, the calcium content is 24m%, and the sulfur content is 0.95m%; m %, the sulfur content is 6.8 m %; the molybdenum content of the molybdenum dialkyl dithiophosphate is 14 m %, the sulfur content is 6.0 m %, the phosphorus content is 2.0 m %, and the nitrogen content is 0.25 m %;

[0060] Mix the second-class hydrogenated base oil 500N, polyα-olefin...

Embodiment 3

[0063] Example 3 20W / 50-SL / CI general internal combustion engine lubricating oil

[0064] Weigh raw materials according to the following weight percentages:

[0065] Type III hydrogenated base oil 500SN 50.9998%;

[0066] 20% polyalphaolefin with a molecular weight of 10,000;

[0067] High base number synthetic calcium sulfonate 20%;

[0068] Thionium butoctyl zinc salt 2%;

[0069] Ethylene-propylene copolymer with a molecular weight of 15,000 5%;

[0070] Dialkylmolybdenum dithiophosphate 2%;

[0071] Methyl silicone oil 0.0002%;

[0072] The total base number of the synthetic calcium sulfonate with high base value is 500, and the calcium content is 30.0 m%, and the sulfur content is 1.0 m %; 2.2m%, the sulfur content is 7.9m%; the molybdenum content of the molybdenum dialkyl dithiophosphate is 14.5m%, the sulfur content is 6.5m%, the phosphorus content is 3.3m%, and the nitrogen content is 0.3m% .

[0073] Mix the three types of hydrogenated base oil 500SN, polyα-ol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com