System and method for injecting fuel

A fuel and pre-injection technology, which is applied in the field of fuel injection systems and methods, can solve problems such as not being within the ideal range, and achieve the effect of avoiding gradual conversion and reducing the amount of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

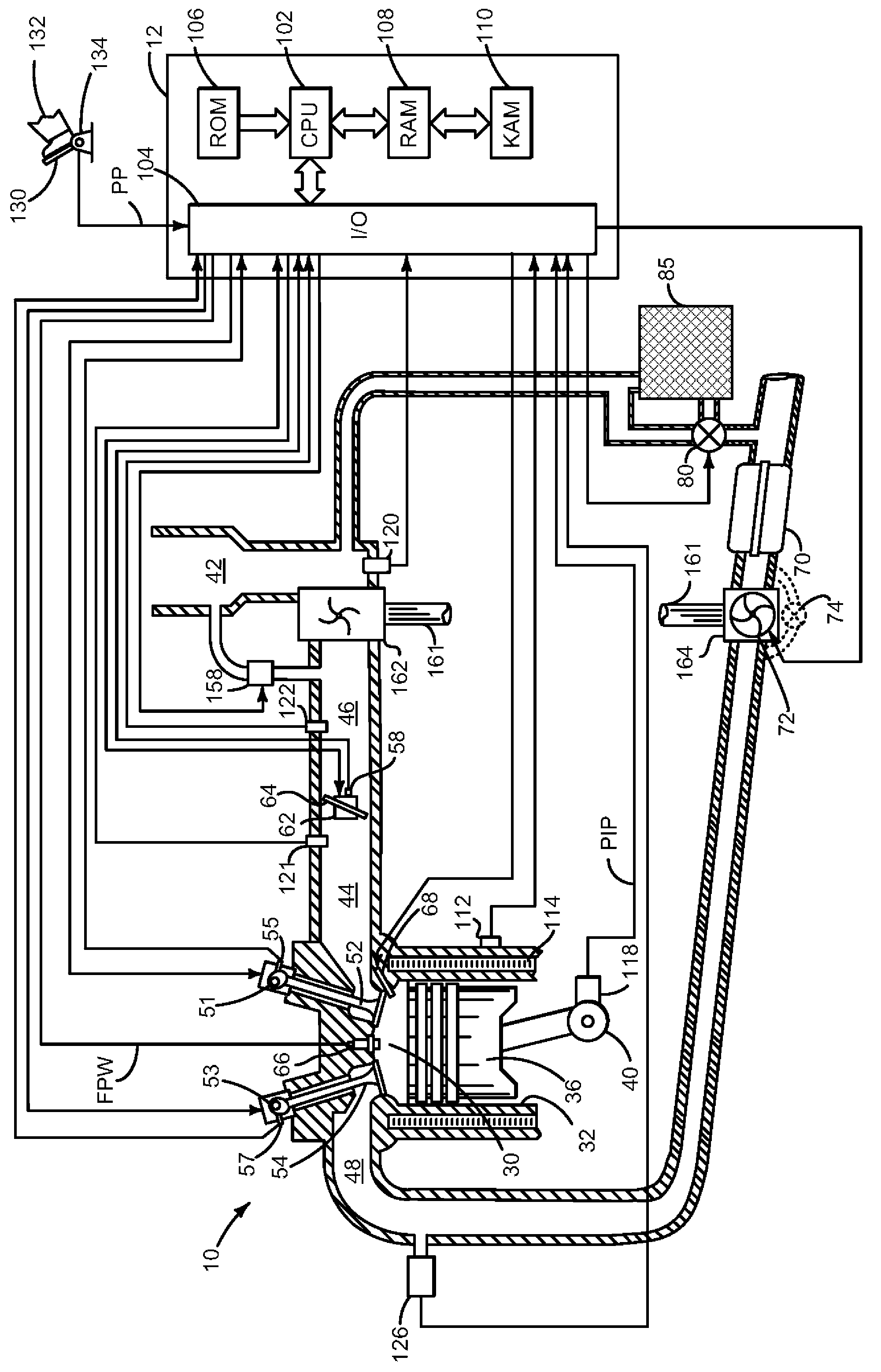

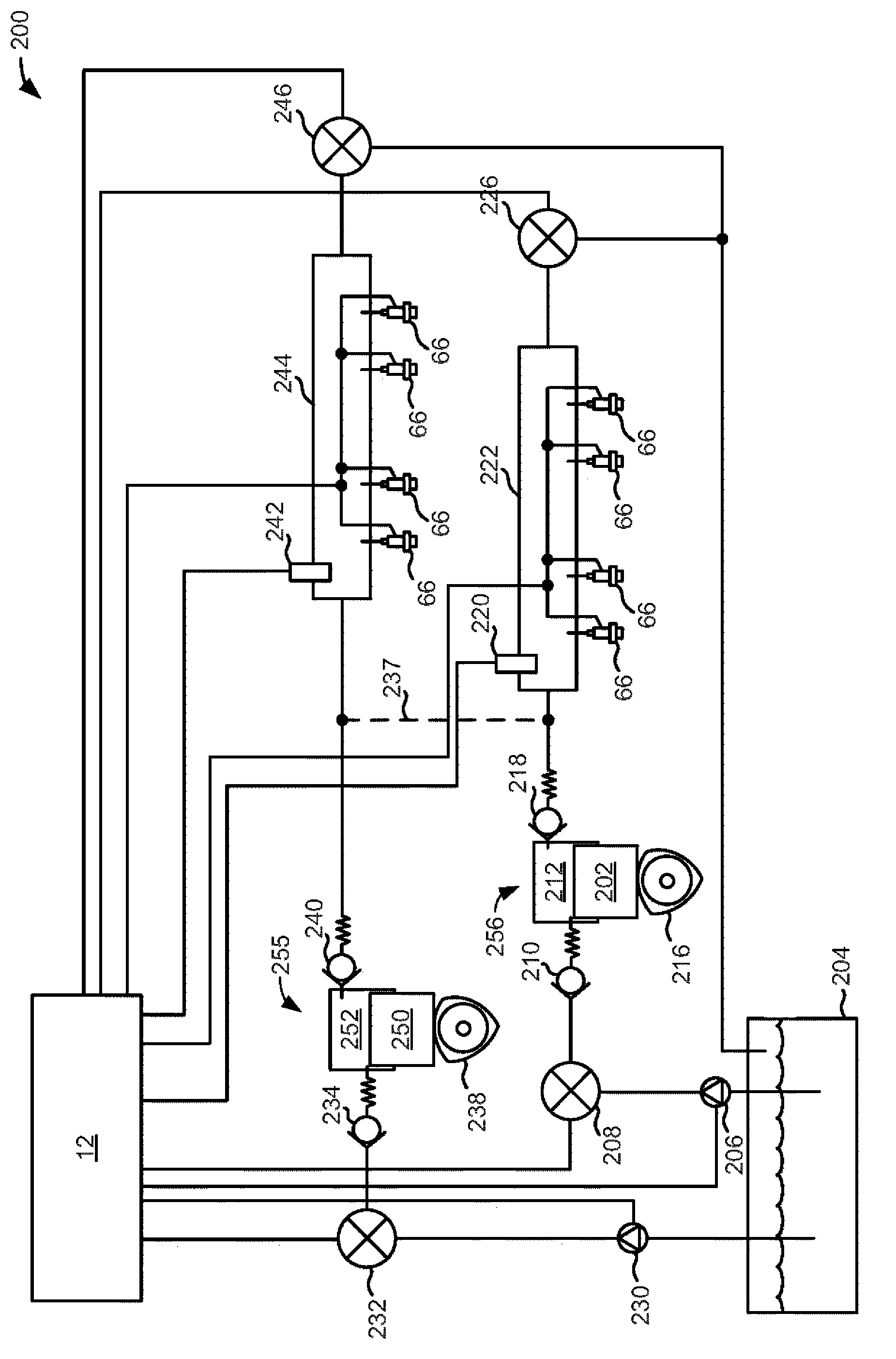

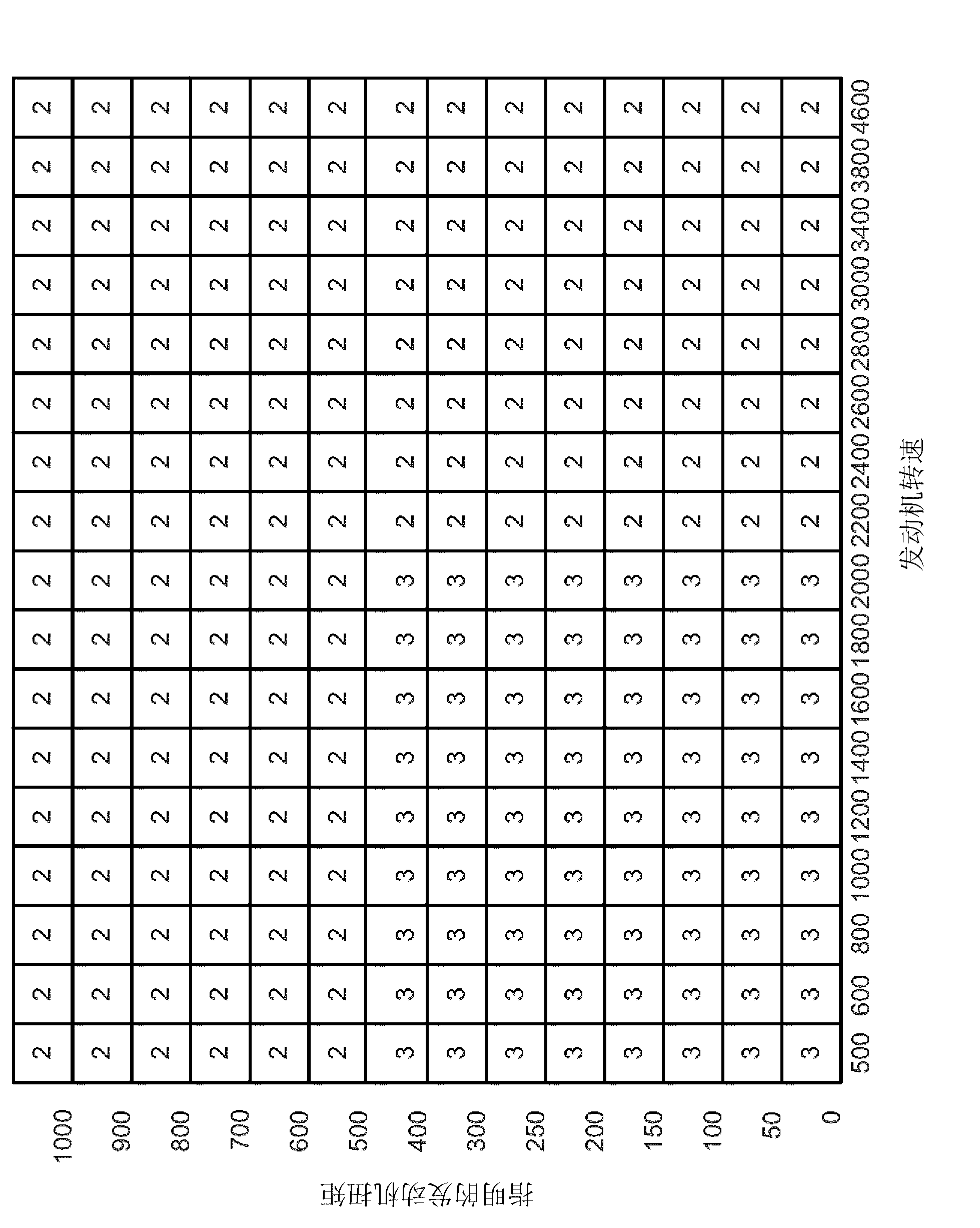

[0028] The invention relates to compensating for changes in the number of pilot fuel injections delivered to a cylinder during a cylinder cycle. figure 1 An example of a supercharged diesel engine is shown, where Figure 10 A method to adjust the number of pilot fuel injections and fuel pressure to improve engine emissions and / or reduce combustion noise. figure 2 An example fuel delivery system for an engine with two cylinder banks is shown. image 3 An example map of pilot fuel injection is shown. Figure 4-5 and Figure 8-9 An example of fuel pressure adjustment in response to the number of pilot fuel injection pulses is shown. Image 6 and 7 An example cylinder layout and firing order with two cylinder banks is shown. at last, Figure 10 is a flowchart of an example method of adjusting fuel pressure and an amount of pilot fuel injection supplied to cylinders of an engine.

[0029] see figure 1 , an internal combustion engine 10 comprising a plurality of cylinders i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com