Pipeline depressurization device

A pressure-reducing device and pipeline technology, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as blockage of pressure-reducing components, complexity of pressure-reducing components, and high equipment costs, and achieve easy maintenance and operation. Simple structure, intensified friction and collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

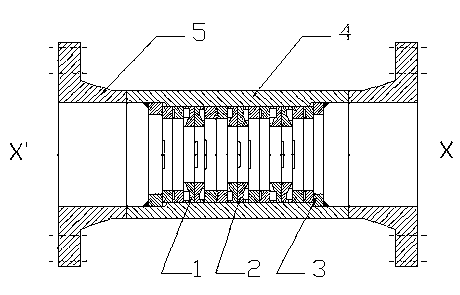

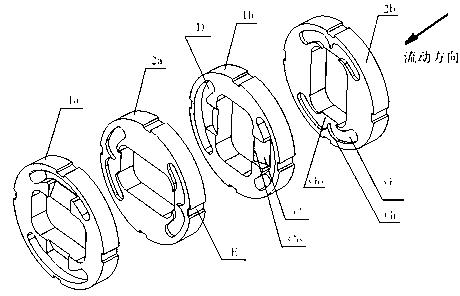

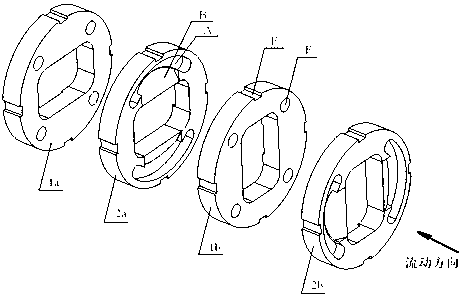

[0008] like figure 1 As shown, the pipeline depressurization device includes a main body of the pipeline depressurization device composed of a straight pipe section 4 and a neck flange 5, and a rectangular hole diversion plate 1 and a rectangular hole diverter plate 2 are superimposed to form a multi-stage depressurization group. , the positioning ring 3 is welded on the inner wall of the pipeline to fix the pressure reducing element. The rectangular hole guide plate 1 and the rectangular hole flow distribution plate 2 are formed into a rectangular hole pressure reduction group in pairs according to the principle of parallel rectangular flow channel walls. The walls are stacked vertically, with the XX' axis as the center line. Multiple pairs of rectangular hole pressure-reducing elements are stacked to form the multi-stage pressure-reducing group of this pipeline pressure-reducing device. The pressure-reducing group can be adjusted according to the medium pressure values at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com