Display module with static protection design, and optical film unit utilized by the same

A technology for display modules and optical diaphragms, applied in the direction of static electricity, electrical components, instruments, etc., can solve the problems of static electricity damage, easy damage by external force, easy damage to integrated circuit 30 electronic components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

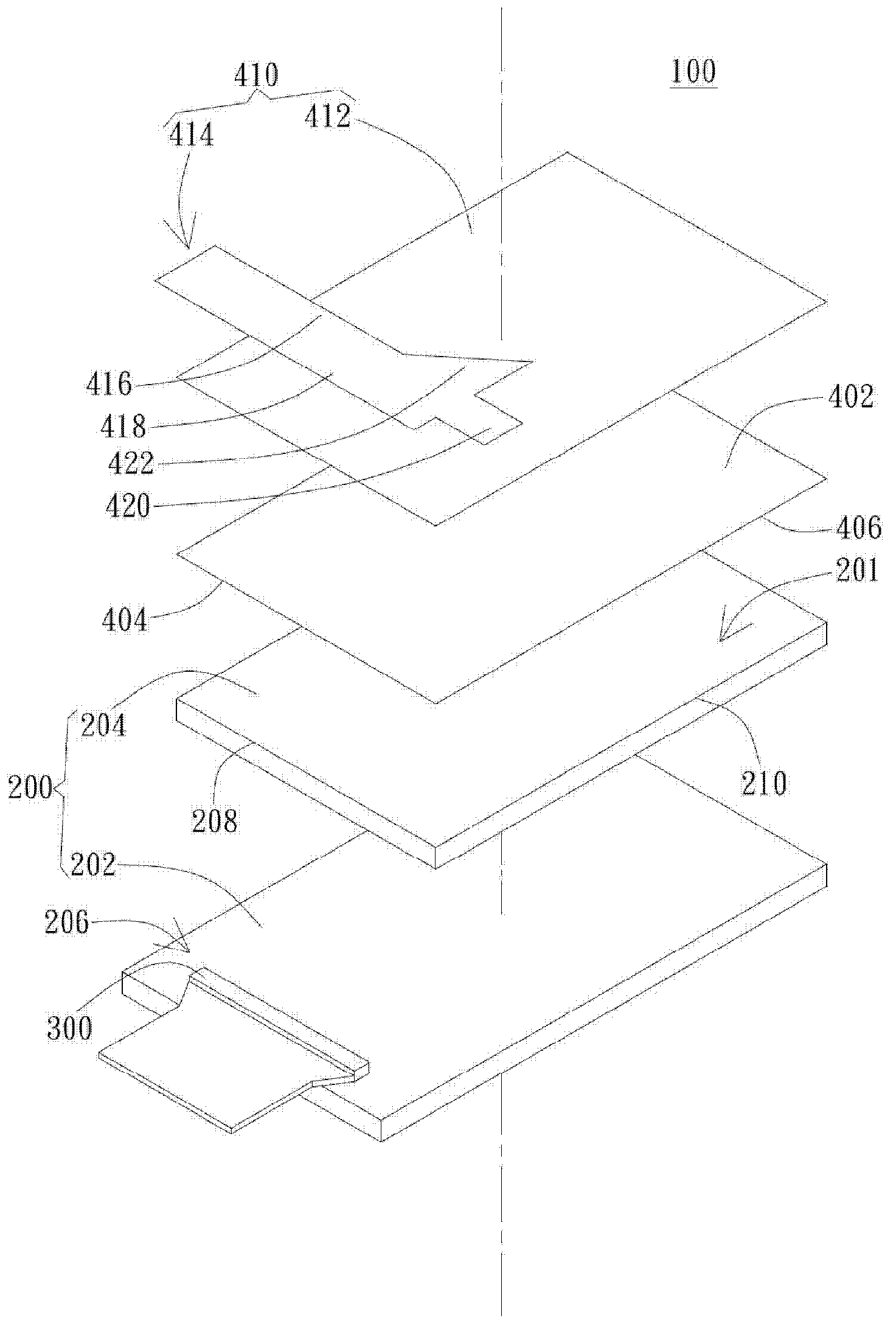

[0046] The display module of the present invention prevents the display module from being damaged during the production process through the protective film layer. The protective film layer has a protective film body attached to the optical film and a release film layer attached to the protective film body. The protective film layer of the present invention can preferably be applied in the production process of display devices such as smart phones, LCD TVs, and computer screens.

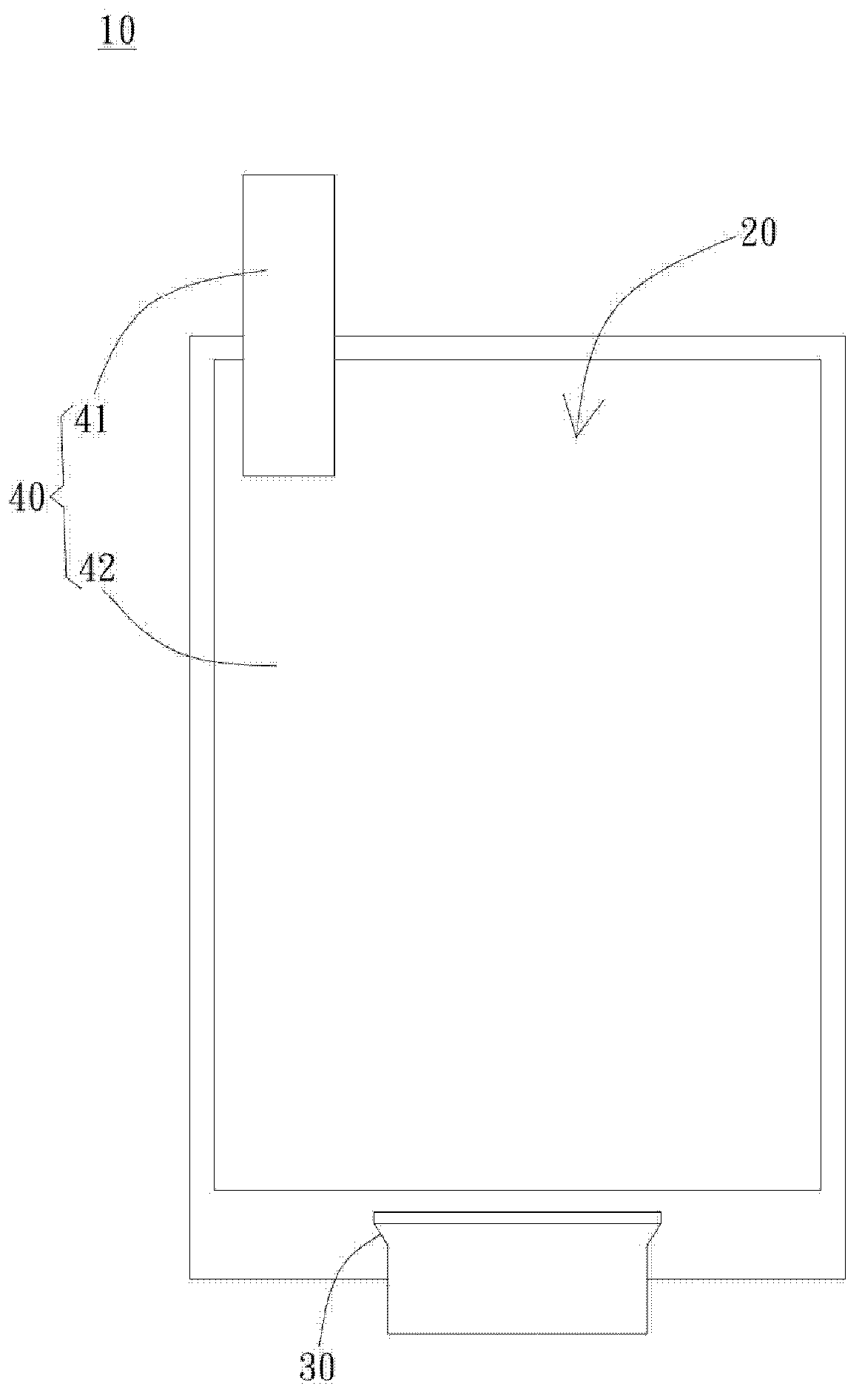

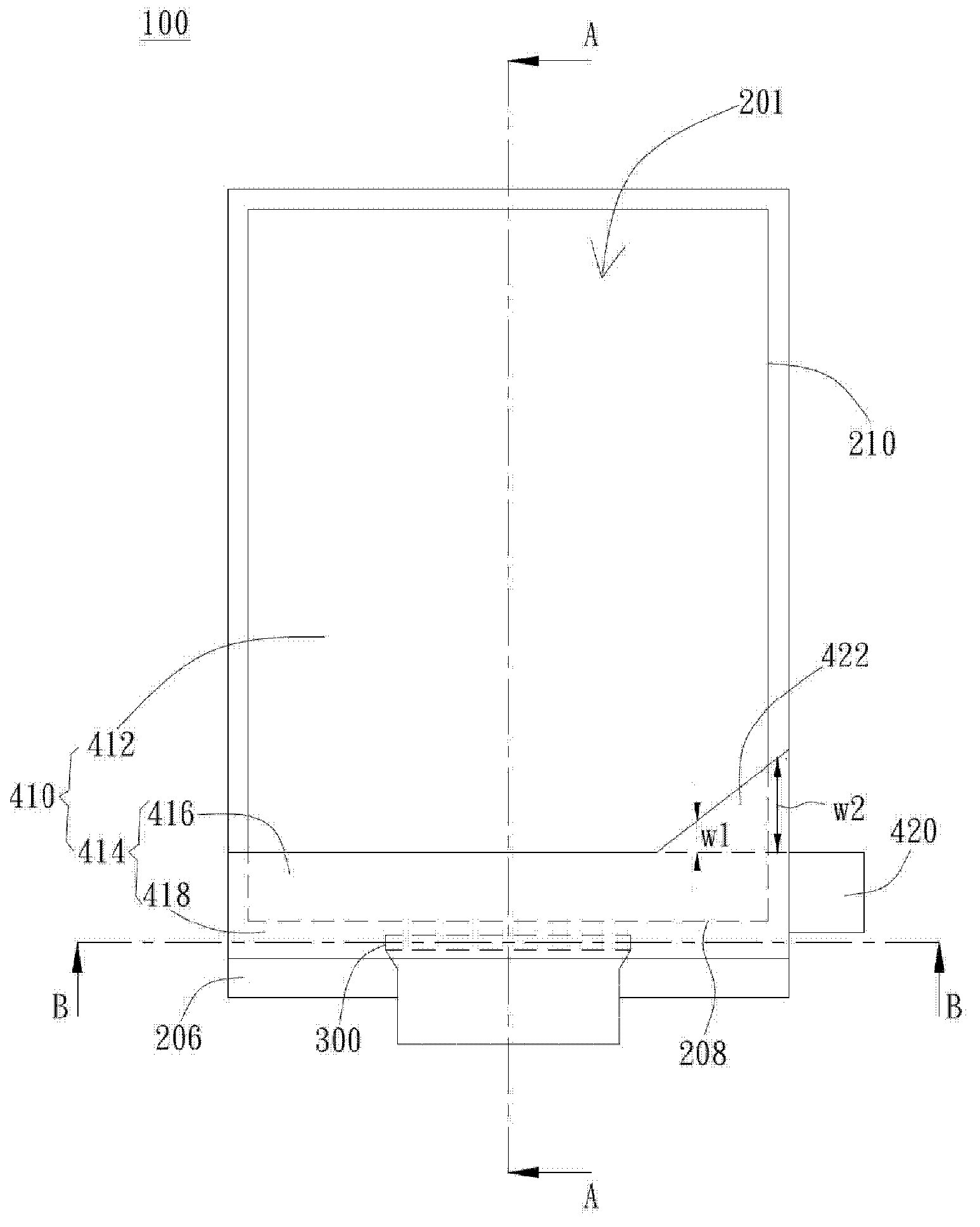

[0047] Figure 2A It is a top view of an embodiment of the display module 100 of the present invention. Such as Figure 2A As shown, the display module 100 has a visible area surface 201 and a protective film layer 410, wherein the protective film layer 410 has a protective film body 412 covering the visible area surface 201 and affixed on the protective film body 412 and along the visible area. The release film layer 414 is distributed on the first side 208 of the surface 201 . Please refer to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com