Hammer with a cutting attachment and a base body

A hammer head and seat body technology, applied in grain processing and other directions, can solve the problems of time-consuming, reduced manufacturing cost, etc., and achieve the effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

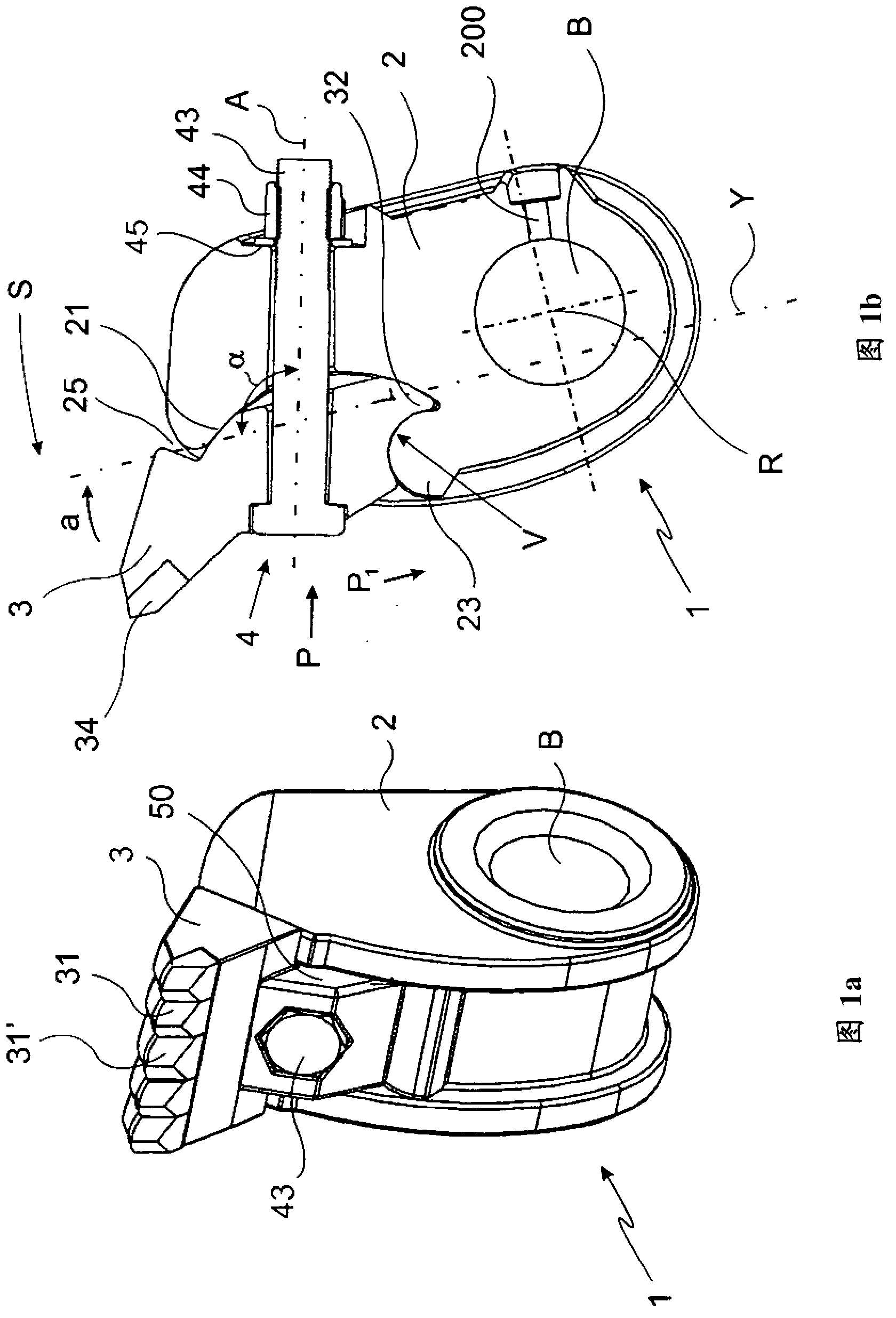

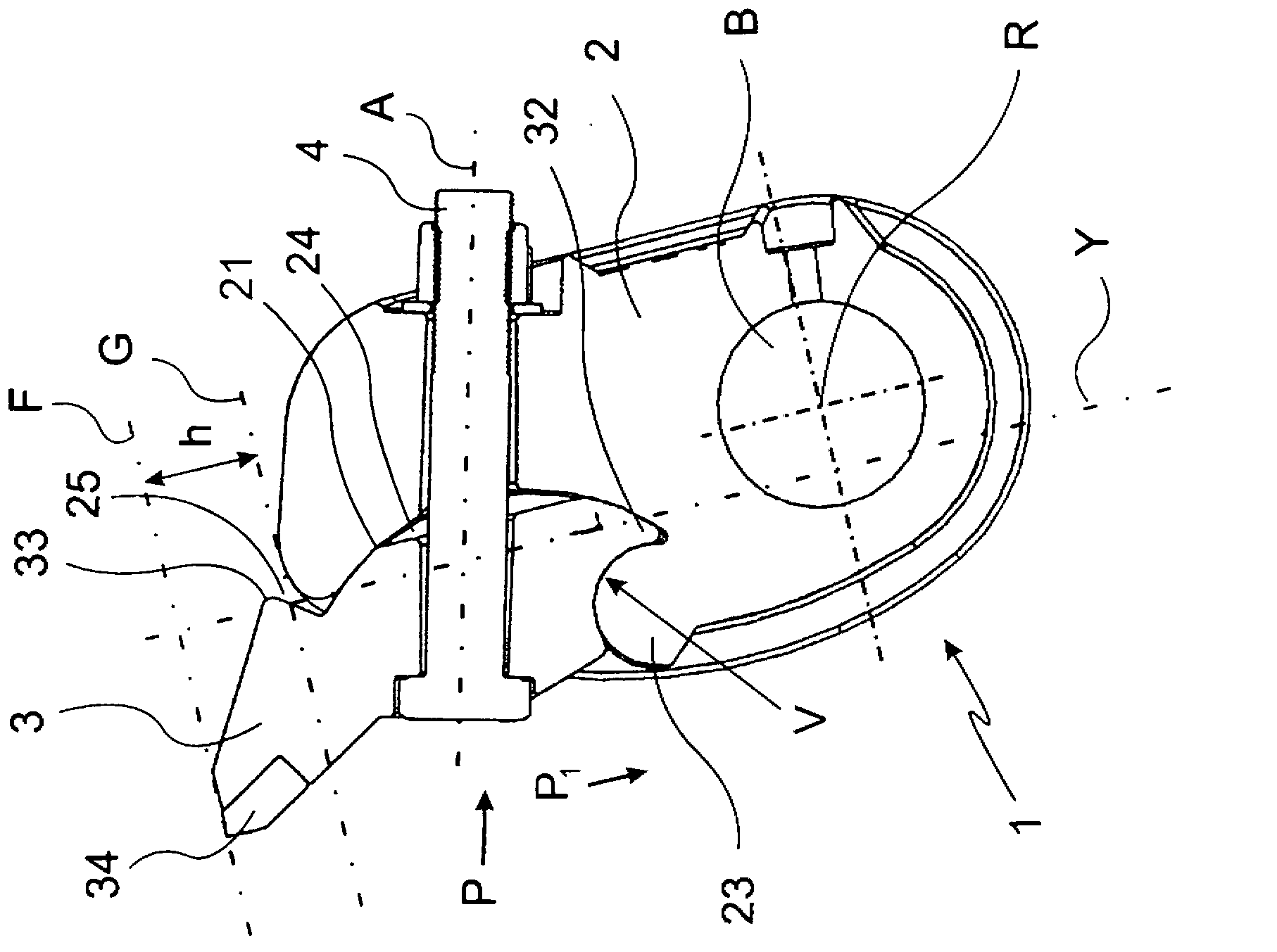

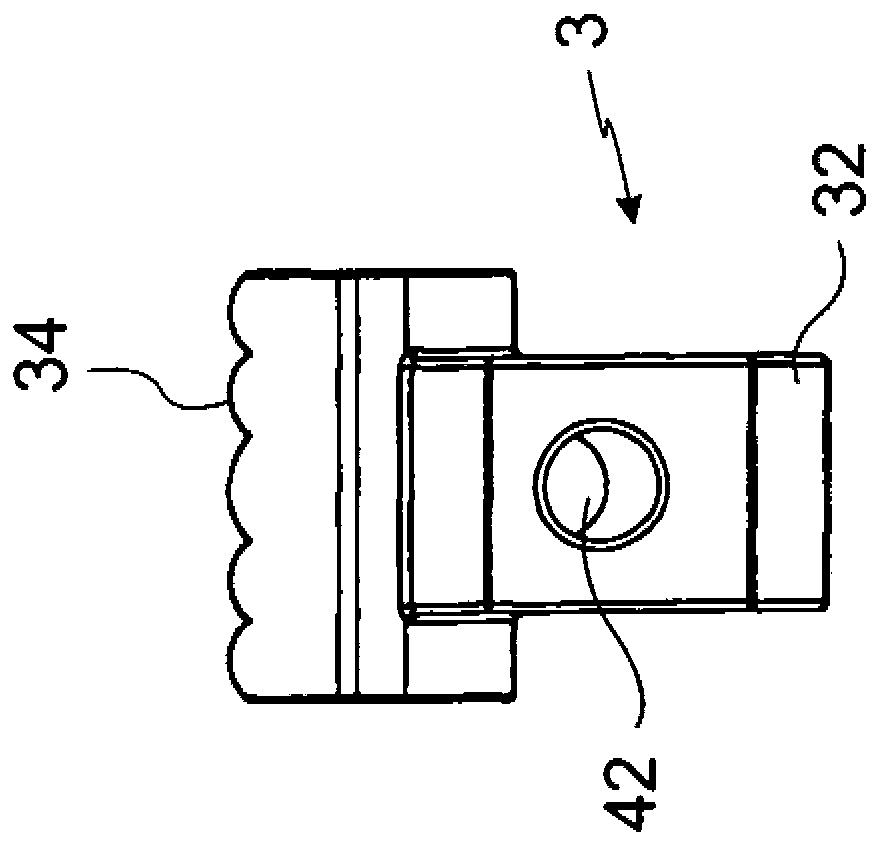

[0037] Figure 1a It is a three-dimensional schematic diagram of a hammer head 1 according to an embodiment of the present invention. Wherein, the base body 2 has a through hole B, and the through hole B is used for connecting the hammer head 1 with the rotor and / or a rotating shaft (not shown in the figure) of a pulverizing device. The body 2 has a cutting attachment 3, the entire surface of which corresponds to the positive connection V is surrounded by the body 2, as shown. The cutting attachment 3 has cutting edges and / or cutting edges 31 , 31 ′. Such as Figure 1a In the embodiment shown, the cutting edge is, for example, welded-on hardened sheet metal. However, it is not restricted to this embodiment, but various variations are possible. The hammer head represented by an arrow is generally designated by component number 1 . Positive lock connection V at Figure 1b There are other more obvious signs. It is marked with an English letter V and is formed on the base 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com