High-pressure pump

A technology for high-pressure pumps and pump components, which is applied in the direction of pumps, multi-cylinder pumps, fuel injection pumps, etc., can solve problems such as pump damage, and achieve the effects of improving lubrication, reducing friction, and improving hydraulic lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

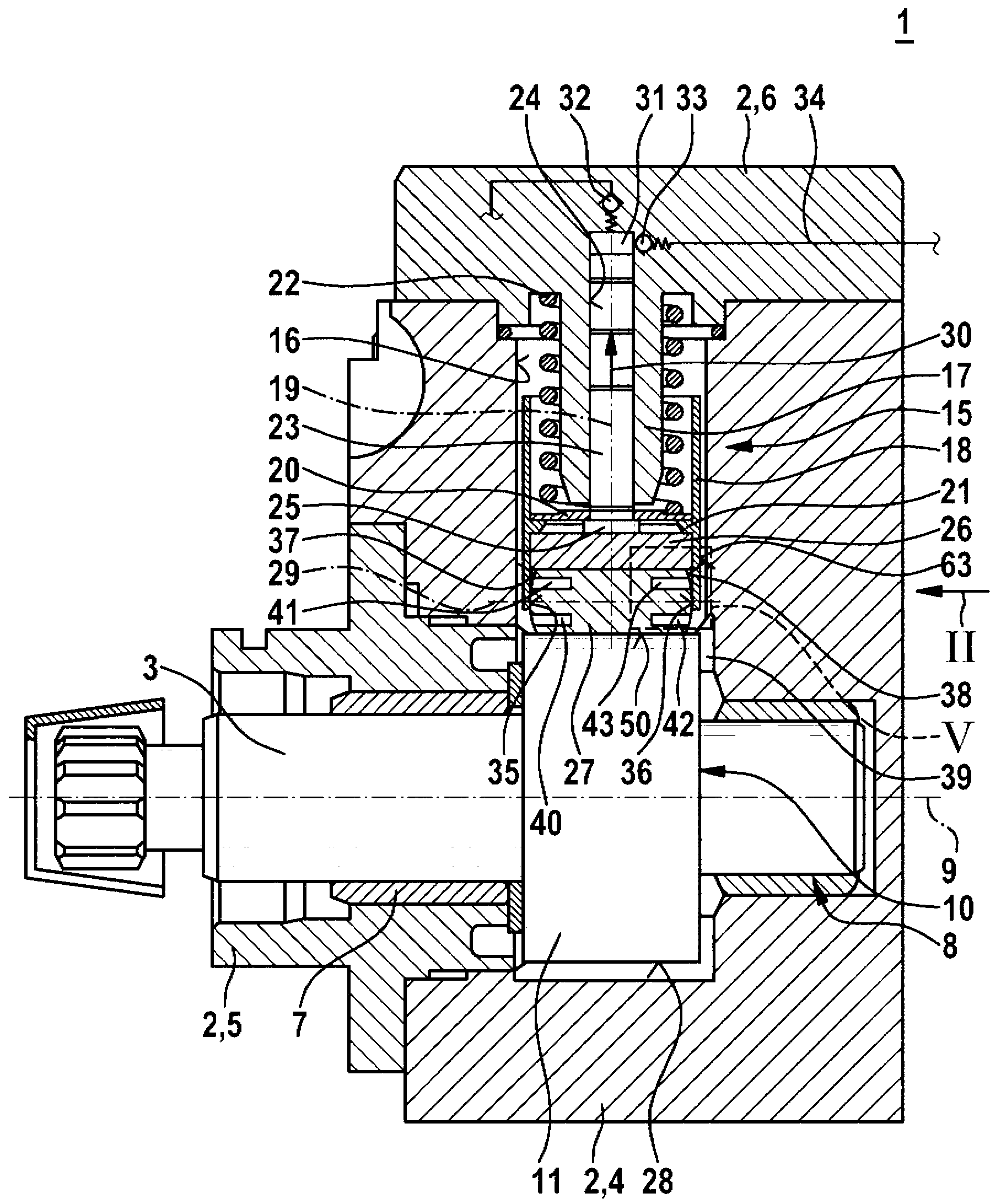

[0017] figure 1 The high-pressure pump 1 corresponding to the first exemplary embodiment of the invention is shown in a schematic axial section. The high-pressure pump 1 can in particular be designed as a radial or in-line piston pump. Specifically, the high-pressure pump 1 is suitable for use as a fuel pump for a fuel injection system of an air-compressed self-ignition internal combustion engine. A preferred use of the high-pressure pump 1 is a fuel injection system with a fuel distributor platen, where high-pressure diesel fuel is stored. However, the high-pressure pump 1 according to the invention is also suitable for other applications.

[0018] The high-pressure pump 1 has a multi-part pump housing 2 and a drive shaft 3 arranged in the pump housing 2 . In this exemplary embodiment, the pump housing 2 comprises a base body 4 , a flange 5 connected to the base body and a cylinder head 6 . The drive shaft 3 is mounted on a bearing 7 on one side on the flange 5 and on a b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap