Split bearing cage

A technology for bearing cages and separating bearings, which is applied in the direction of bearings, roller bearings, bearing assembly, etc., and can solve problems such as bearing failures, bearing cage failures, uneven circular outer contours, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

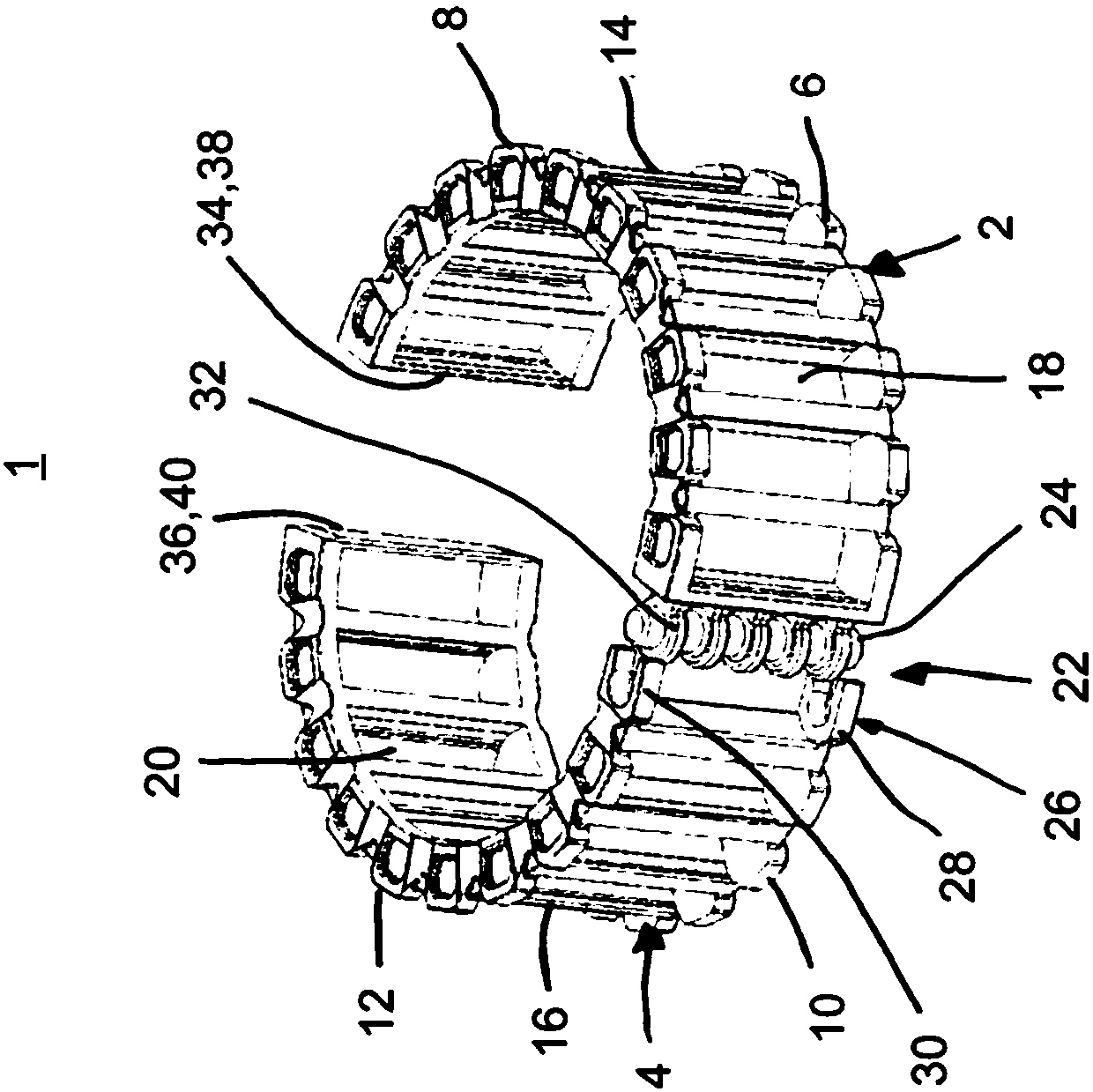

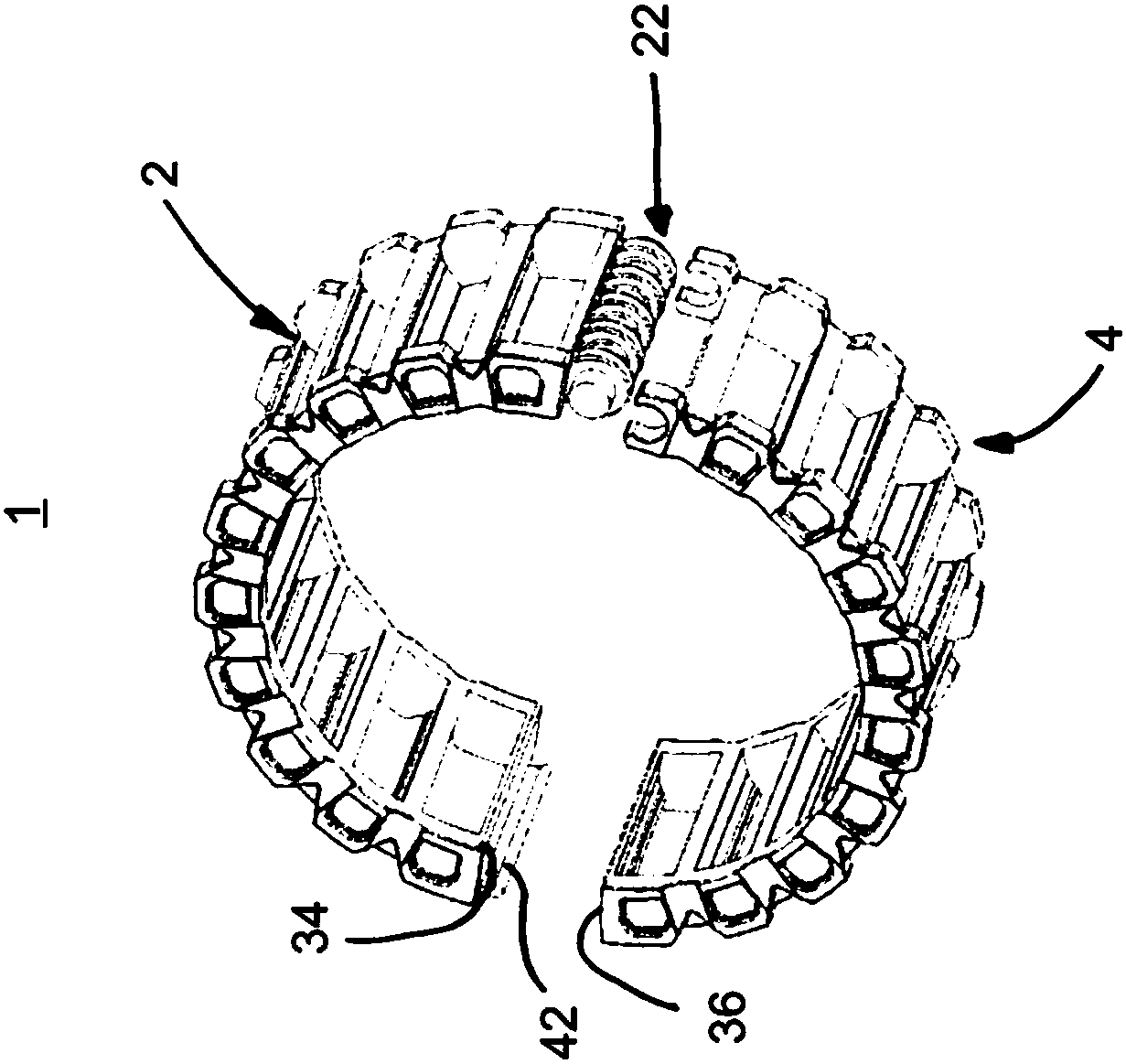

[0024] figure 1 and figure 2 A schematic perspective view of a split bearing cage 1 of a rolling element bearing assembly (not shown) comprising first and second bearing cage segments 2, 4, respectively, is shown. here in figure 2 , an alternative design of the proposed release bearing cage 1 is shown. Furthermore, each bearing cage segment 2, 4 comprises two side ring portions 6, 8, 10, 12, each axially spaced from each other via bridges 14, 16, between which rolling element receiving recesses are formed 18, 20. The rolling element receiving pockets 18, 20 are configured to receive rolling elements (not shown) of the rolling element bearing assembly to keep them spaced from each other and to guide them.

[0025] In order to improve the operating behavior of the split bearing cage 1 , especially for use with a one-piece crankshaft, the two bearing cage segments 2 , 4 are connected to each other via a rotary joint arrangement 22 .

[0026] like figure 1 and 2 As shown,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap