Plant shaping mould

A mold and plant technology, applied in the field of horticulture, can solve the problems of poor universality and industrial standardized process manufacturing, and achieve the effects of high yield, compliance with plant growth habits, and easier mastery of operation techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

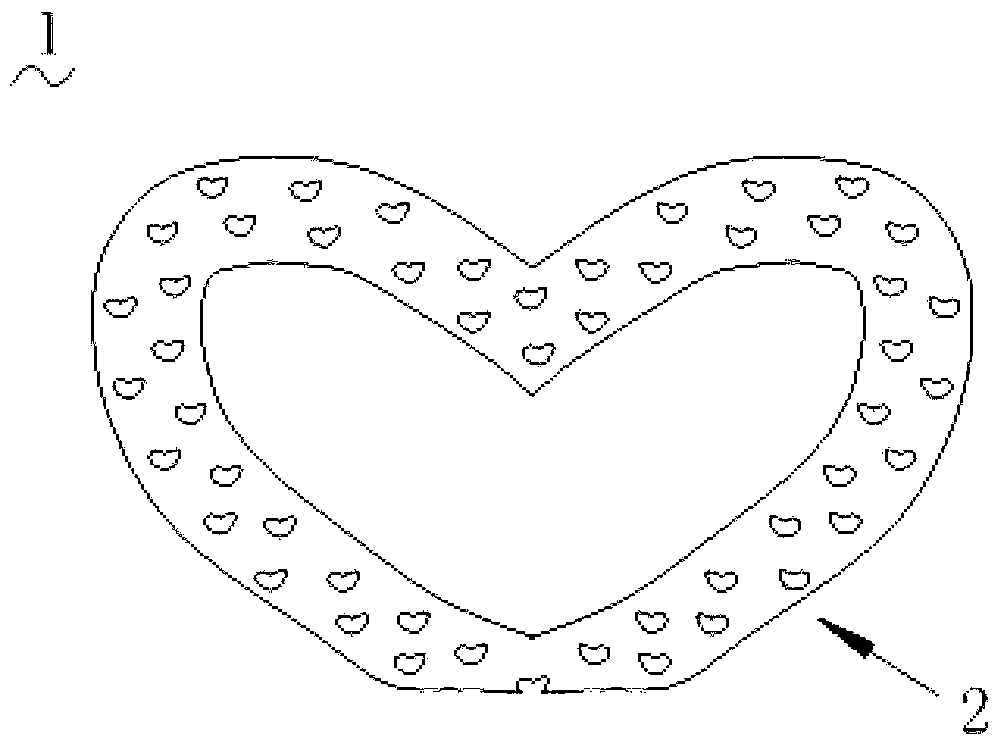

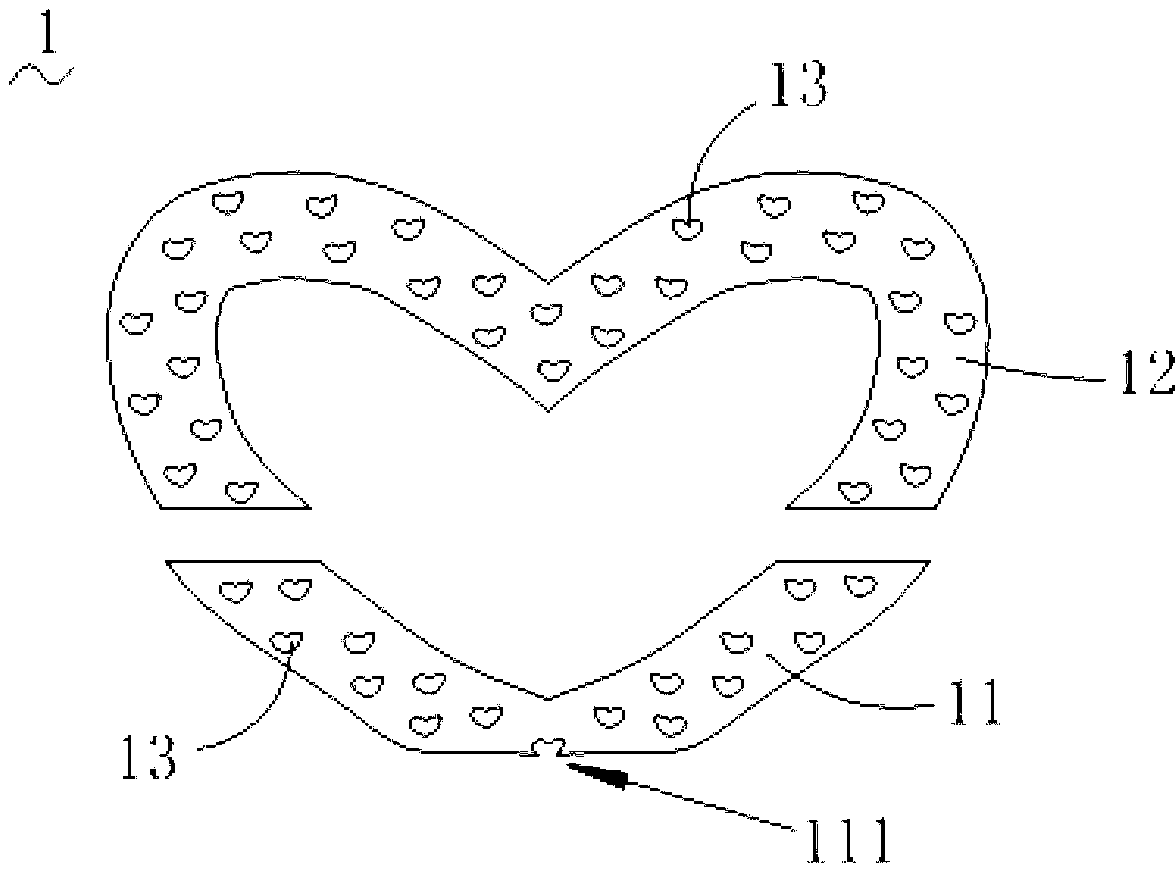

[0020] see figure 1 , figure 2 , figure 1 Shown is the structural representation of the plant shaping mold of the present invention. figure 2 Shown is a schematic structural view of the first embodiment of the plant molding mold of the present invention. Described plant shaping mold 1 comprises at least a first mold shell 11 and a second mold shell 12 that is combined with the first mold shell 11 to form the structure 2 to be shaped, and is spaced apart from the first mold shell 11. On the mold shell 11 and the second mold shell 12, there are supply holes 13 for supplying the plants to be shaped.

[0021] As a person skilled in the art, it is not difficult to understand that since plant shaping takes a certain amount of time, and the growth environment is mostly outdoors, in order to avoid damage to the plant shaping mold 1 after being exposed to the sun and rain, the plant shaping mold 1 The production materials must be durable, can be used many times, reduce costs, and...

no. 2 approach

[0030] The difference between the second embodiment and the first embodiment is that the structure to be shaped formed by the plant shaping mold is a dynamic yoga shape. The components in the second embodiment are numbered with the same numbers as those in the first embodiment, and the similarities will not be repeated here.

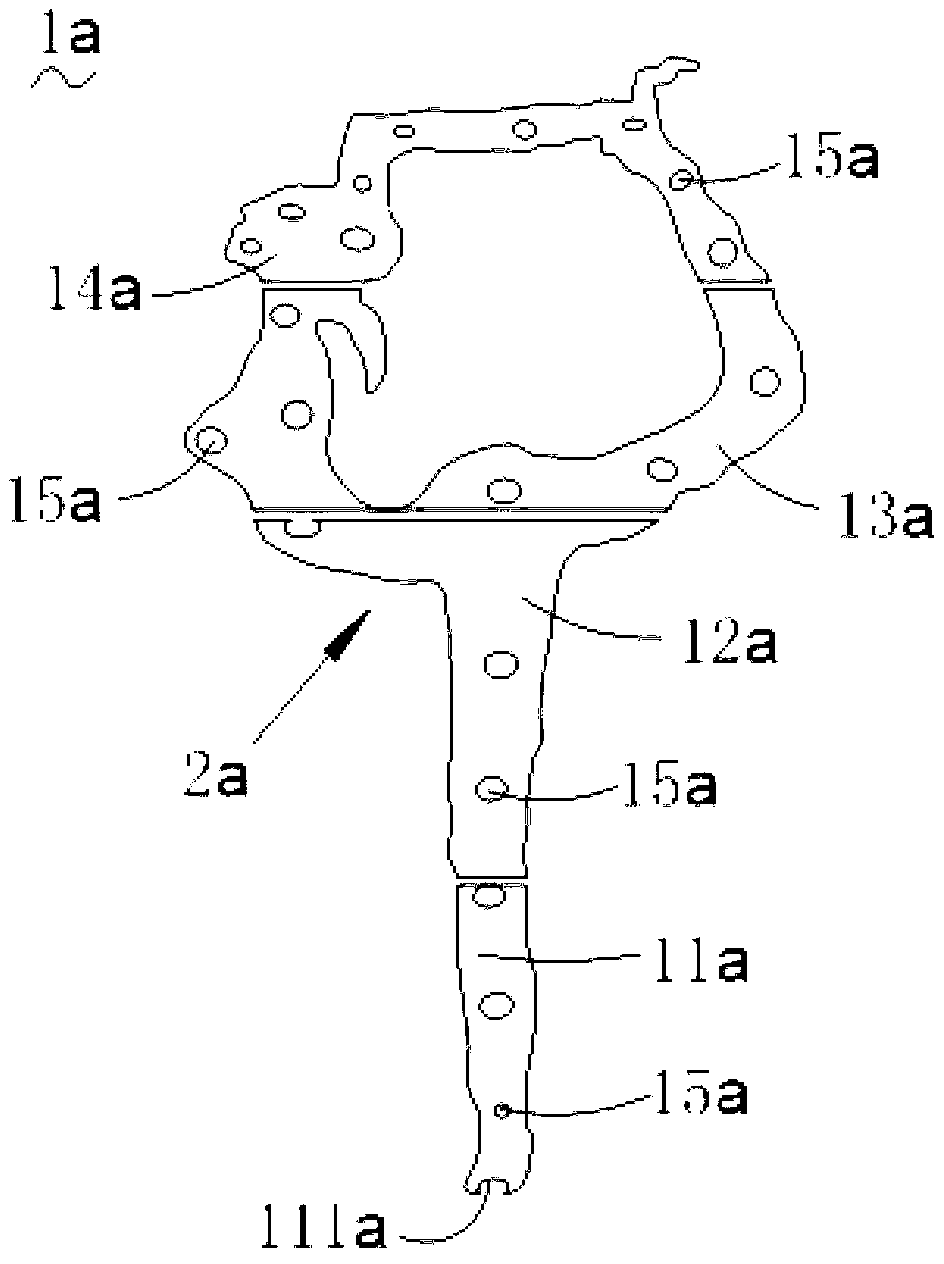

[0031] see image 3 , image 3 Shown is a schematic structural view of the second embodiment of the plant shaping mold of the present invention. When the structure to be shaped 2a formed by the plant shaping mold 1a is in a dynamic yoga shape, the mold to be shaped 1a includes an independently provided first mold shell 11a, a second mold shell 12a, a third Mold shell 13a, and the 4th mold shell 14a, and described first mold shell 11a, the second mold shell 12a, the 3rd mold shell 13a, and the to-be-shaped mold shell 14a combined formation Structure 2a is in the shape of a dynamic yoga. In order to ensure the normal growth of the plant to be shaped, f...

no. 3 approach

[0034] The difference between the third embodiment and the first embodiment is that the structure to be shaped formed by the plant shaping mold is an animal shape. As a non-limiting example, the animal is in the shape of a deer. The components of the third embodiment and the first embodiment are numbered with the same numbers, and the similarities will not be repeated here.

[0035] see Figure 4 , Figure 4 Shown is a schematic structural view of the third embodiment of the plant shaping mold of the present invention. When the structure 2b to be shaped formed by the plant shaping mold 1b is in the shape of a deer in animal form, the said mold to be shaped 1b includes an independently provided first mold shell 11b, a second mold shell 12b, The third mold shell 13b, and the fourth mold shell 14b, and the combination of the first mold shell 11b, the second mold shell 12b, the third mold shell 13b, and the fourth mold shell 14b to be formed The shaping structure 2b is in the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com