A cement-soil retaining wall pouring row pile and its construction method

A construction method and cement-soil technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of weakening the friction resistance of the pile side, weakening the bearing capacity of the pile end, secondary pollution, etc., and making the pile quality easy to control. , The effect of rapid construction of piles and enhanced water-retaining capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

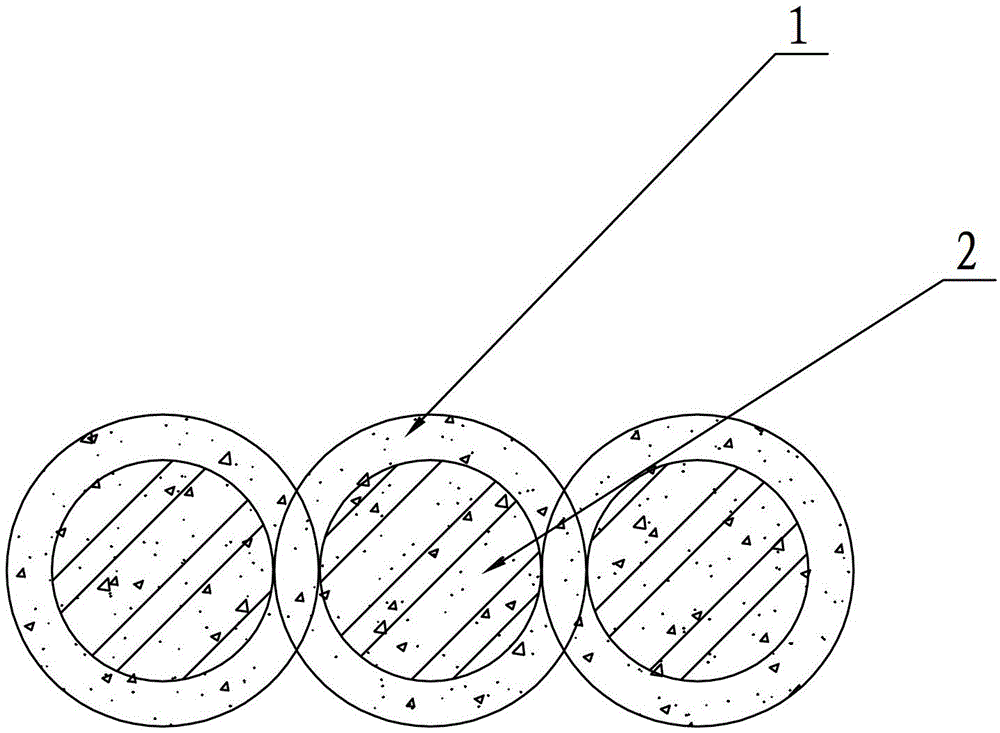

[0018] refer to figure 1 , the present invention is a kind of cast-in-place pile for cement-soil retaining wall, including several mixing piles 1 arranged according to the extension direction of the cement-soil retaining cast-in-place pile support structure, any stirring pile 1 is partially embedded in another adjacent stirring pile 1, each mixing pile 1 is provided with cast-in-situ piles 2.

[0019] As a preferred embodiment of the present invention, the stirring pile 1 is cylindrical.

[0020] As a preferred embodiment of the present invention, two adjacent stirring piles intersect, and the intersecting thickness is not less than 100 mm.

[0021] A construction method of the above-mentioned cement-soil retaining wall pouring cast-in-place piles is characterized in that it comprises the following steps:

[0022] 1) The center of the mixing head of the cement-soil mixer is aligned with the center of the design pile position circle of the cement-soil mixing pile, sinking to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com