Water plugging agent, preparation method and application thereof

A technology of water blocking agent and plasticizer, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well parts, etc., and can solve the problems of complex synthesis process, high cost, and high residue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

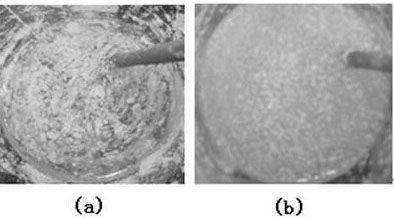

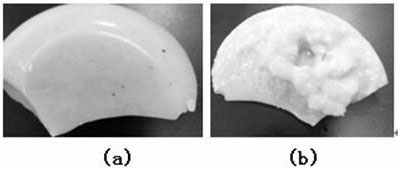

Image

Examples

Embodiment 1

[0034] The present invention provides a synthesis scheme of a selective water shutoff agent for oil and gas wells used in 40°C reservoirs, including the following steps:

[0035]Step 1: Since the melting temperature of the oil-soluble resin is between 130-140°C, but burning may occur when the melting temperature is higher than 200°C, in order to shorten the melting time, save energy and ensure production safety, the 65 % of the oil-soluble resin is melted when heated to 180°C-200°C;

[0036] Step 2: After the oil-soluble resin is completely melted into a liquid state, add 25% plasticizer, stir evenly, and add 0.7% cross-linking agent under stirring conditions;

[0037] Step 3: In order to ensure that the cross-linking agent is fully mixed, fully reacted and saves energy consumption, the stirring reaction time is controlled between 30-50 minutes, which can be adjusted according to the actual production situation, and then add 4% softening point regulator and stir Uniform, in o...

Embodiment 2

[0045] A synthetic scheme of a selective water shutoff agent for oil and gas wells used in 150°C reservoirs, comprising the following steps:

[0046] Step 1: Since the melting temperature of the oil-soluble resin is between 130-140°C, but when the melting temperature is higher than 200°C, it may burn, so in order to shorten the melting time, save energy and ensure production safety, 90% The oil-soluble resin is melted when heated to 180°C-200°C;

[0047] Step 2: After the oil-soluble resin is completely melted, add 3% plasticizer, stir evenly, and add 1% crosslinking agent under stirring condition;

[0048] Step 3: In order to ensure that the cross-linking agent is fully mixed, fully reacted and saves energy consumption, the stirring reaction time is controlled between 40-70 minutes, which can be adjusted according to the actual production situation, and then 2% softening point regulator is added and stirred Uniform, in order to ensure that the system state has good fluidity ...

Embodiment 3

[0054] A method for preparing a selective water shutoff agent for oil and gas wells used in 100°C reservoirs, comprising the following steps:

[0055] Step 1: Since the melting temperature of the oil-soluble resin is between 130-140°C, but when the melting temperature is higher than 200°C, combustion may occur, so in order to shorten the melting time, save energy and ensure production safety, the 83 % of the oil-soluble resin is melted when heated to 180°C-200°C;

[0056] Step 2: After the oil-soluble resin is completely melted, add 8% plasticizer, stir evenly, and add 0.7% crosslinking agent under stirring condition;

[0057] Step 3: In order to ensure that the cross-linking agent is fully mixed, fully reacted and energy-saving, the stirring reaction time is controlled between 40-70 minutes, which can be adjusted according to the actual production situation, and then add 4% softening point regulator, Stir evenly, in order to ensure that the system has good fluidity at this t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com