Integral grouting and water blocking and plugging device

A water-stopping and grouting technology, which is applied in wellbore/well components, mining equipment, earthwork drilling and mining, etc., can solve the problems of not easy to form accumulation, cement is easily washed away by water, and poor water blocking effect, so as to save cement , Improve the effect of water blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

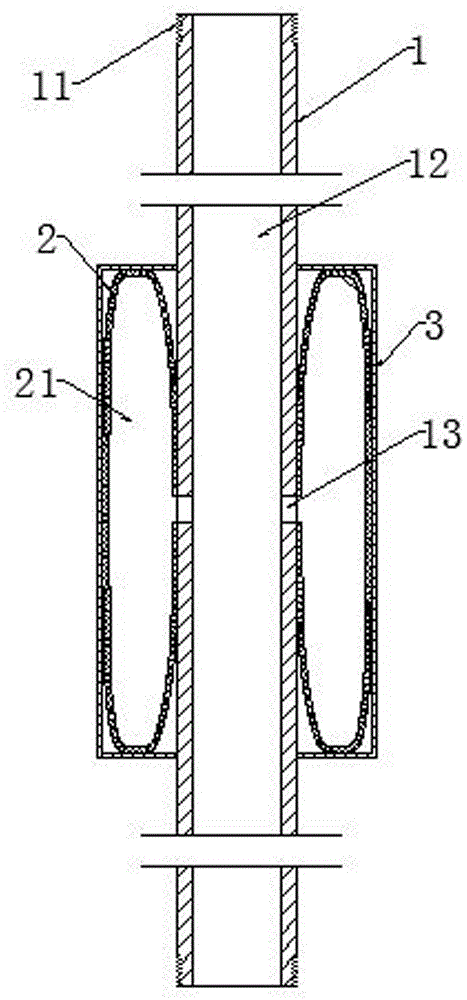

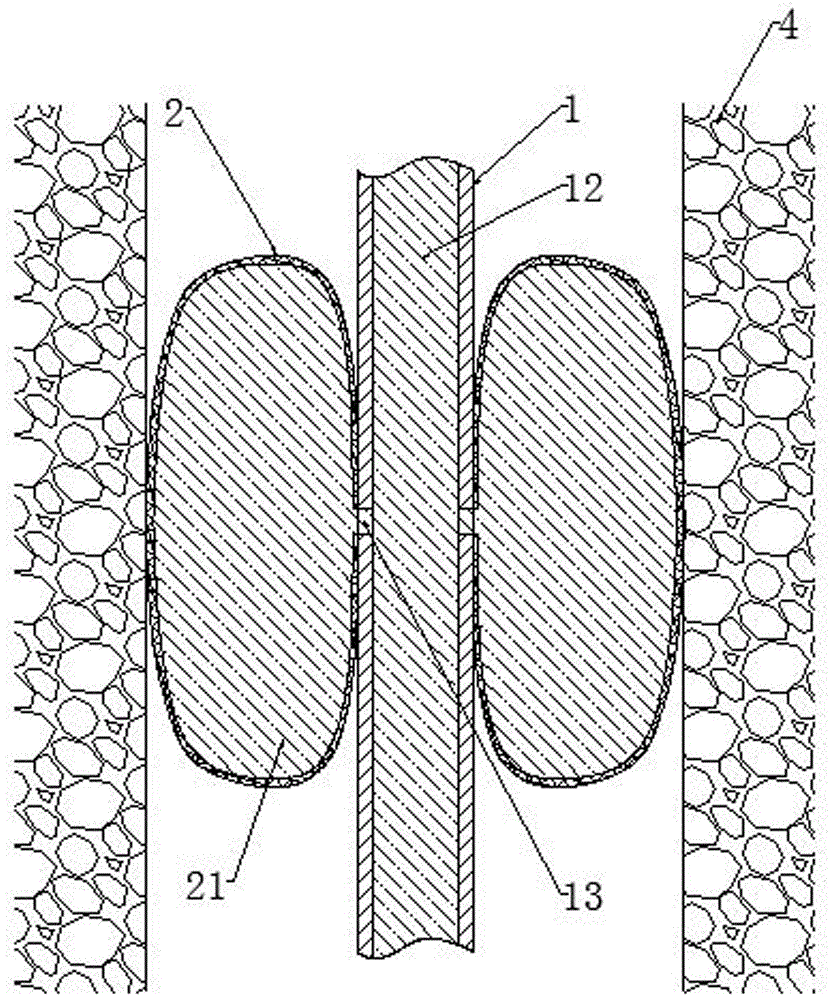

[0018] Embodiment one: see Figure 1-2 , a grouting and water-stopping integrated device, including a bolt 1, the outer circumference of the bolt 1 near both ends is provided with threaded fasteners 11, and the multi-section bolt 1 or the bolt 1 is connected to the anchor drill bit through the threaded fasteners 11 . The anchor rod 1 is provided with a central hole 12 through both ends, the pipe wall of the anchor rod 1 is provided with a side hole 13, the outer circumference of the anchor rod 1 is provided with a destructible protective shell 3, and the protective shell 3 is provided with a bag made of elastic material The bag 2 , the pouch 2 is a pouch made of rubber material, and the pouch chamber 21 of the pouch 2 communicates with the central hole 12 of the anchor rod 1 through the side hole 13 .

[0019] When the bolt is transported, assembled or used normally, the bag 2 is in a contracted state, and the protective shell 3 is used to protect the bag 2 from damage by ext...

Embodiment 2

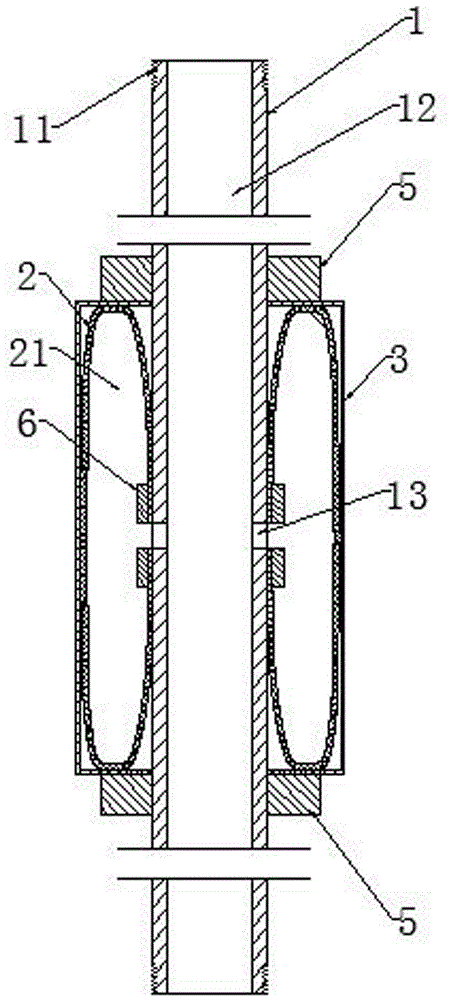

[0020] Embodiment two: see image 3 , Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be described in detail. The difference is that a clip 6 is provided in the pouch cavity 21 of the pouch 2, and the pouch 6 makes the pouch 2 close to the outside of the anchor rod. The peripheral bladder wall is fixed together with the corresponding anchor rod 1 . Blocking platforms 5 are respectively fixed on the outer circumference of the anchor rod 1 at both ends of the protective shell 3 .

[0021] The bladder 2 is fixed on the anchor rod 1 through the clamp 6, and the outer circumference of the anchor rod 1 at both ends of the protective shell 3 is respectively fixed with stoppers 5 to prevent the bladder 2 from sliding axially along the anchor rod 1 when the water pressure is high , to enhance the water blocking effect of the capsule bag 2.

Embodiment 3

[0022] Embodiment three: see image 3 , the third embodiment is basically the same as the second embodiment, and the similarities will not be repeated. The difference is that the anchor rod 1 is provided with two bladder groups along the axial direction, and each bladder group includes a bladder 2, which is located at The protective shell 3 on the outside of the pouch 2 , the hoop 6 arranged in the pouch cavity 21 and the blocks 5 arranged at both ends of the protective shell 3 . The anchor rod 1 is provided with two bladder groups along the axial direction, forming two-stage waterproof layers, and improving the overall water blocking effect of the integrated grouting, water-stopping and water-blocking device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com