Environment-friendly waterproof cable for high-speed rail transit and preparation method

A technology for waterproof cables and high-speed rails, which is applied in the direction of cable/conductor manufacturing, insulating cables, and conductor/cable insulation. It can solve the problems of affecting the service life of cables, limited water blocking effect, and many production processes, and achieves UV curing speed. Fast, excellent water resistance and water resistance, the effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

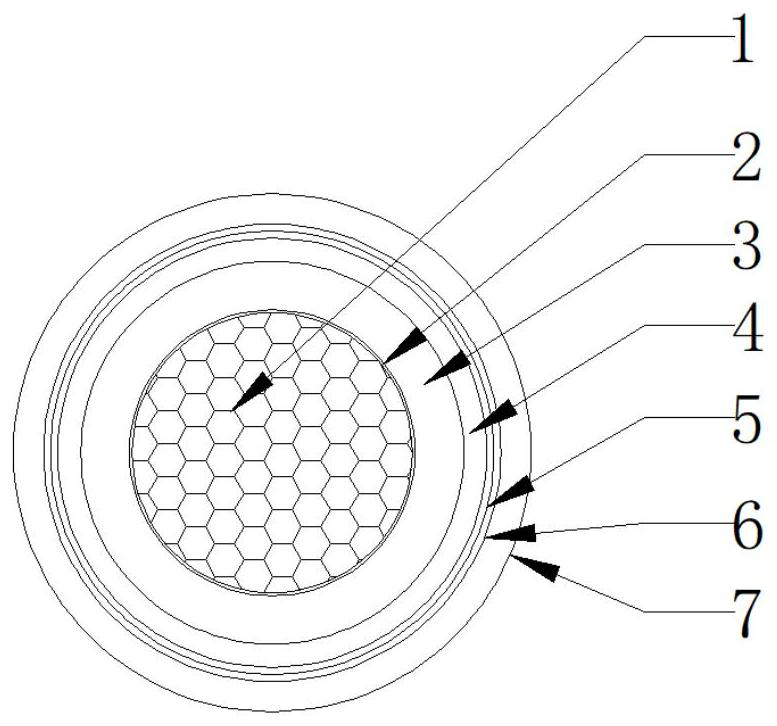

[0045] like figure 1 As shown, an environment-friendly waterproof cable for high-speed rail transit, including a conductor 1, a tape 2, an insulating layer 3, an inner sheath 4, a flame-retardant wrapping layer 5, a water-blocking layer 6 and The outer sheath 7, the conductor 1 is a type 5 copper conductor or a type 2 tight copper conductor, the wrapping tape 2 is made of polyester non-woven fabric, the lapping rate of the wrapping is 15% to 20%, the insulating layer 3 is made of EPR material or XLPE Material, the extrusion method is extrusion type, the inner sheath 4 is made of halogen-free low-smoke flame-retardant polyolefin material, the flame-retardant wrapping layer 5 is made of halogen-free low-smo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com