Water resistant high-voltage cable and production method thereof

A technology of high-voltage cables and manufacturing methods, which is applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of limited water-blocking effect and limited water-blocking powder attachment, achieve the best water-blocking effect, and the manufacturing process is easy and improved. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An embodiment of the present invention provides a water-blocking high-voltage cable, which includes a wire core and a wire core sleeve wrapping the wire core. The wire core includes a plurality of conductors, and a fragile water-blocking tape is wound on the conductors. The tape includes semi-conductive brittle non-woven fabric and water-blocking powder. The semi-conductive brittle non-woven fabric is wrapped with water-blocking powder. When the wire core is under pressure, the semi-conductive brittle non-woven fabric is broken, and the water-blocking powder fills the gap between conductors.

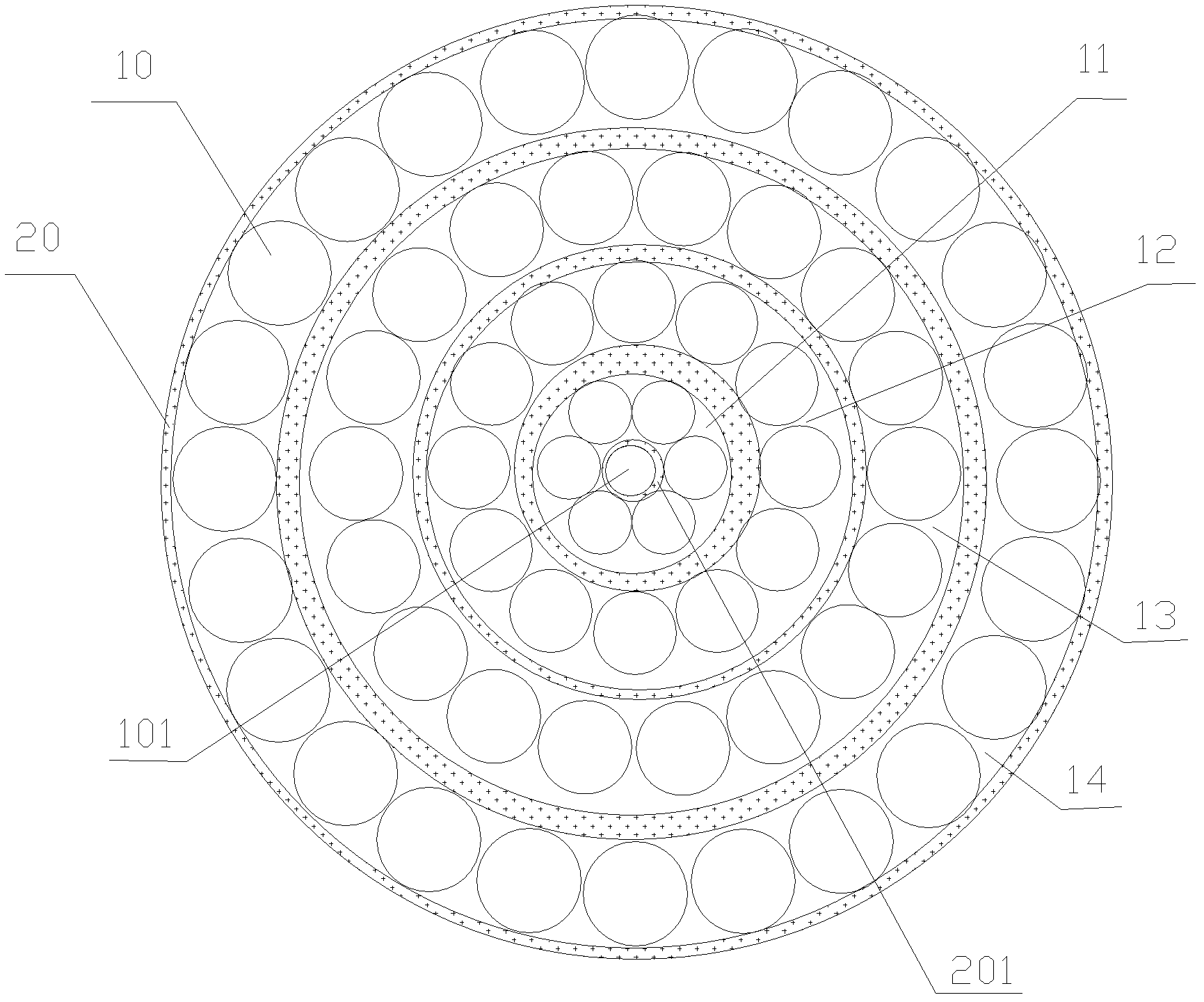

[0032] Specific as figure 1 As shown, the wire core is composed of a plurality of conductors 10, and the conductors 10 form an inner core 11, a secondary inner core 12, a secondary outer core 13 and an outer core 14 from the inside to the outside; the inner core 11, the secondary inner core 12, the secondary outer core Both the core 13 and the outer core 14 are wrapped with a frag...

Embodiment 2

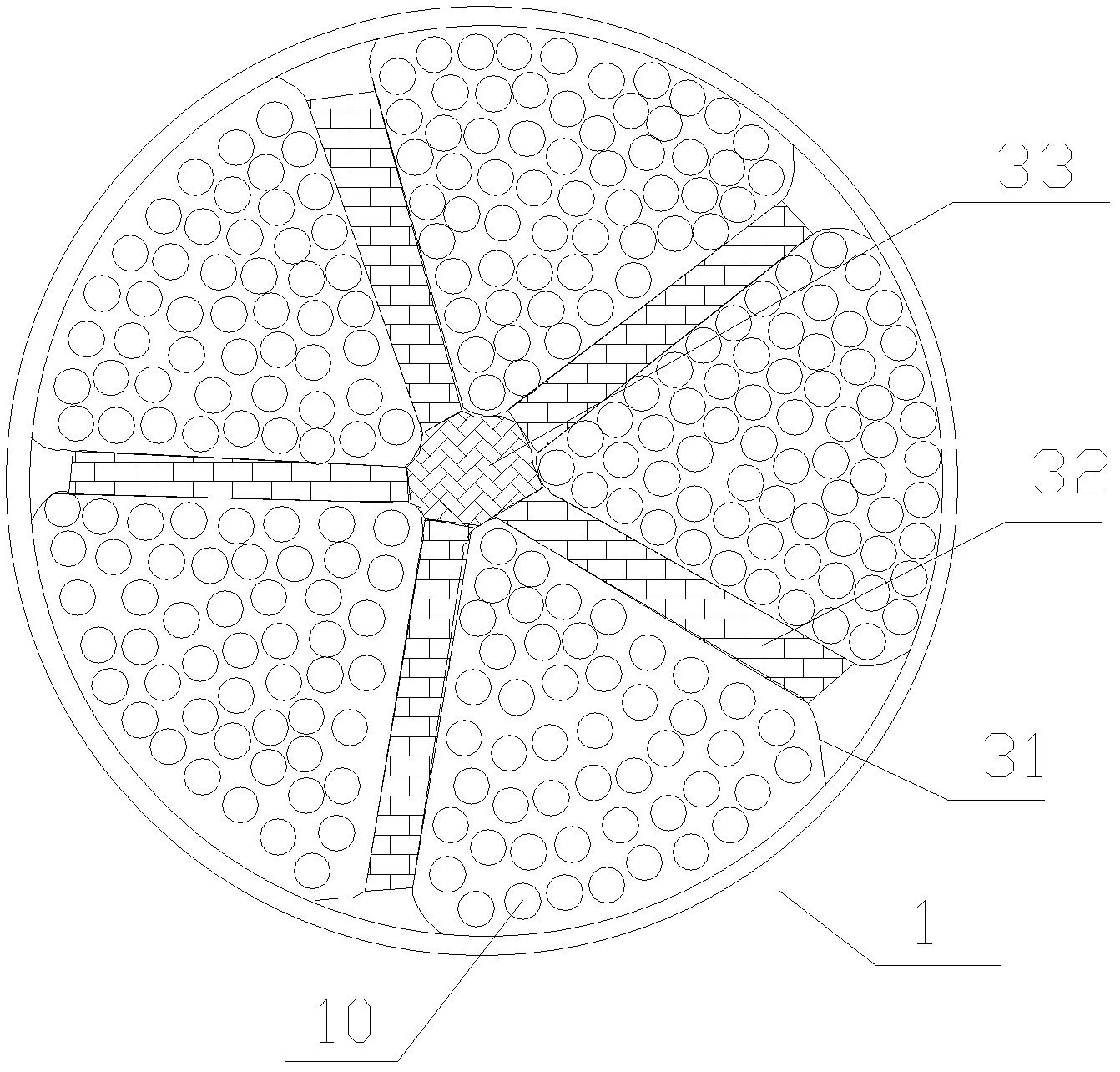

[0036] like image 3 As shown, the wire core 1 is divided into a plurality of sector blocks 31 , belonging to a multi-core cable, and each sector block 31 includes multiple conductors 10 . Double-sided water-blocking and insulating crepe paper 32 is lined between every two fan-shaped blocks. The fan-shaped block 31 forms a central hole in the center of the wire core 1, and a plurality of water-blocking yarns 33 are added to the position of the central hole. For the conductor 10 in the fan-shaped block 31, the method in the above-mentioned embodiment 1 is still adopted, and the conductor 10 is wound with a fragile water-blocking tape. It can be understood that the arrangement of the conductors in the embodiment of the present invention does not need to be layered, so , There are many ways to wrap the conductor with the fragile water-blocking tape. You can use a fragile water-blocking tape to wrap only one conductor, or you can use a fragile water-blocking tape to wrap multiple...

Embodiment 3

[0039]An embodiment of the present invention provides a method for manufacturing a water-blocking high-voltage cable, including making a wire core and a wire core sleeve. When making the wire core, a fragile water-blocking tape is wound on the conductor, and the fragile water-blocking tape includes a semi-conductive Fragile non-woven fabric and water-blocking powder, semi-conductive fragile non-woven fabric wrapped with water-blocking powder.

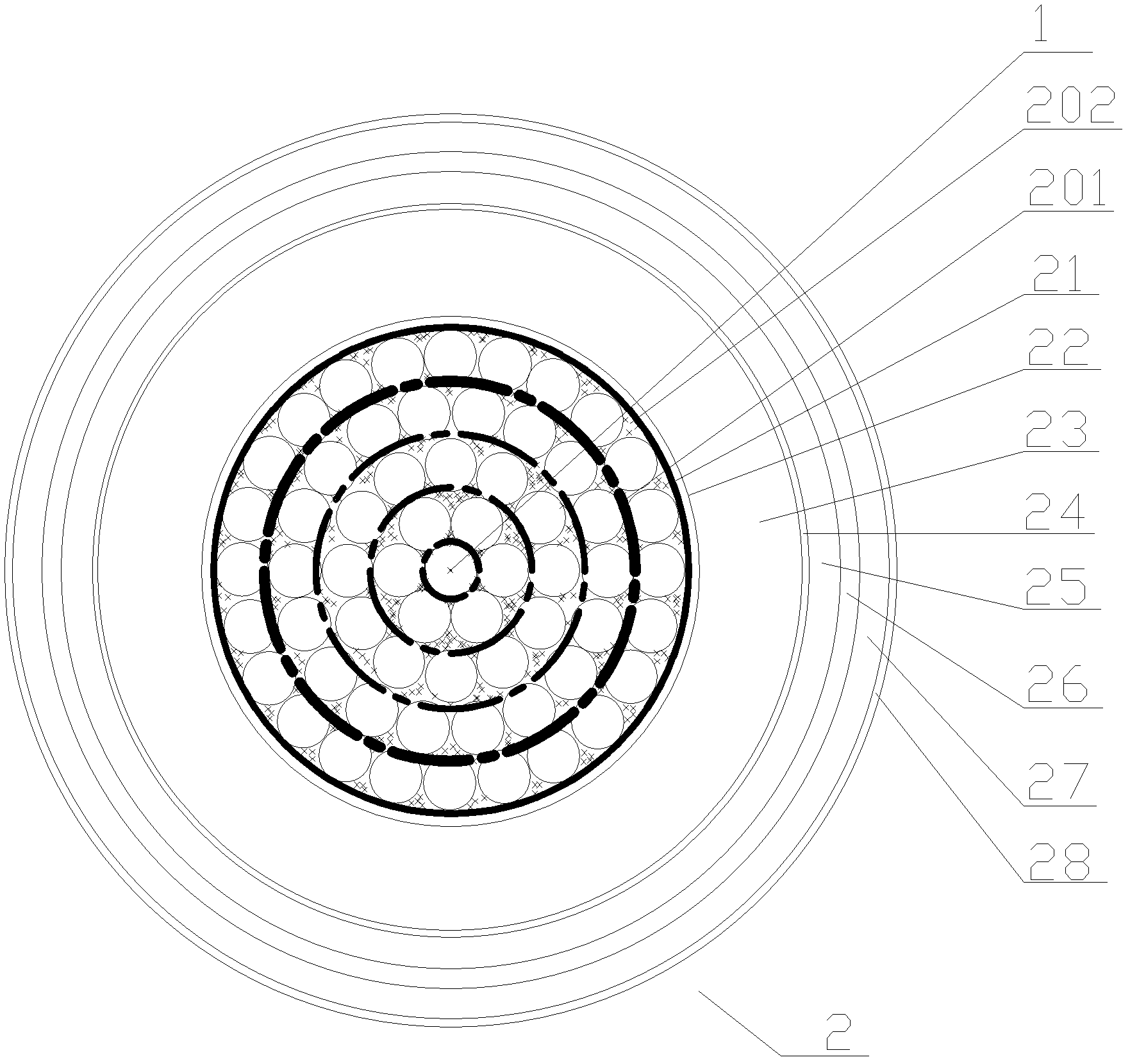

[0040] Specifically, when winding a fragile water-blocking tape on a conductor, it is preferred to arrange multiple conductors closely from the inside to the outside to form a conductor layer with concentric circles, and to wind a fragile water-blocking tape on each layer of conductors.

[0041] As an improvement of the embodiment of the present invention, when winding the fragile water-blocking tape on the conductor, it is also possible to closely arrange multiple conductors to form an inner core, and wind the fragile water-blocking tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com