Automatic dusting device for energy-saving lamps

A technology for energy-saving lamps and automatic wiping, which is applied in the manufacture of discharge tubes/lamps, electrical components, and cold cathodes. The effect of powder is good, and the effect of avoiding the harm of workers' body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

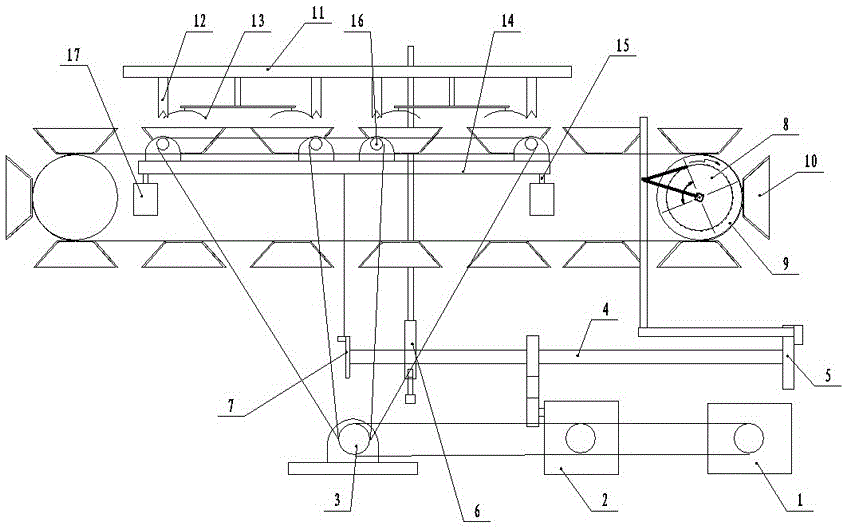

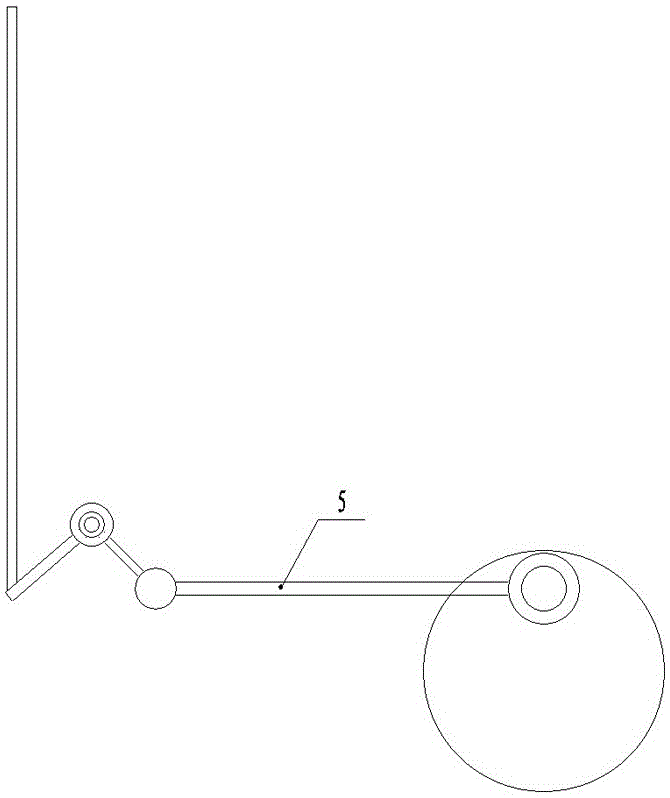

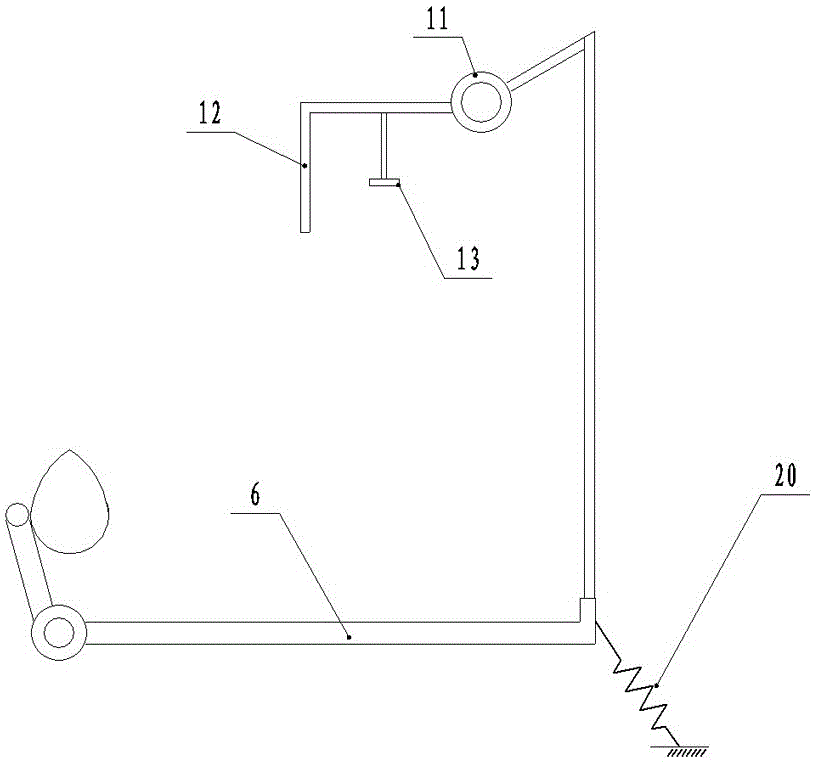

[0015] The energy-saving lamp automatic dusting device includes a transmission device, an energy-saving lamp transmission device, an energy-saving lamp fixing device and a powder wiping device; the transmission device includes a motor 1, and the motor 1 is connected to the worm gear reducer 2 through a belt. The input end of the worm gear reducer 2 is connected to the shaft I3 through a belt, the output end of the worm gear reducer 2 is connected to the shaft II4 through a chain, and two sheaves are arranged on the shaft I3, and the sheaves are connected to the powder wiping device through an elastic belt. One end of II4 located directly below the energy-saving lamp fixing device is connected to the powder wiping device through the crank slider mechanism 7, and the middle part of the shaft II4 is connected to the energy-saving lamp fixing device through the cam slider mechanism 6.

[0016] The energy-saving lamp fixing device includes a rotating shaft 11, and the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com