Wafer powder wiping machine and powder wiping mechanism thereof

A technology of wafers and powder bins, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems such as explosions and fires in dust floating operation workshops, differences in the cleanliness of glass dusting, and hidden dangers to the health of operators. Achieve the effect of simple structure, reasonable design and good powder wiping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

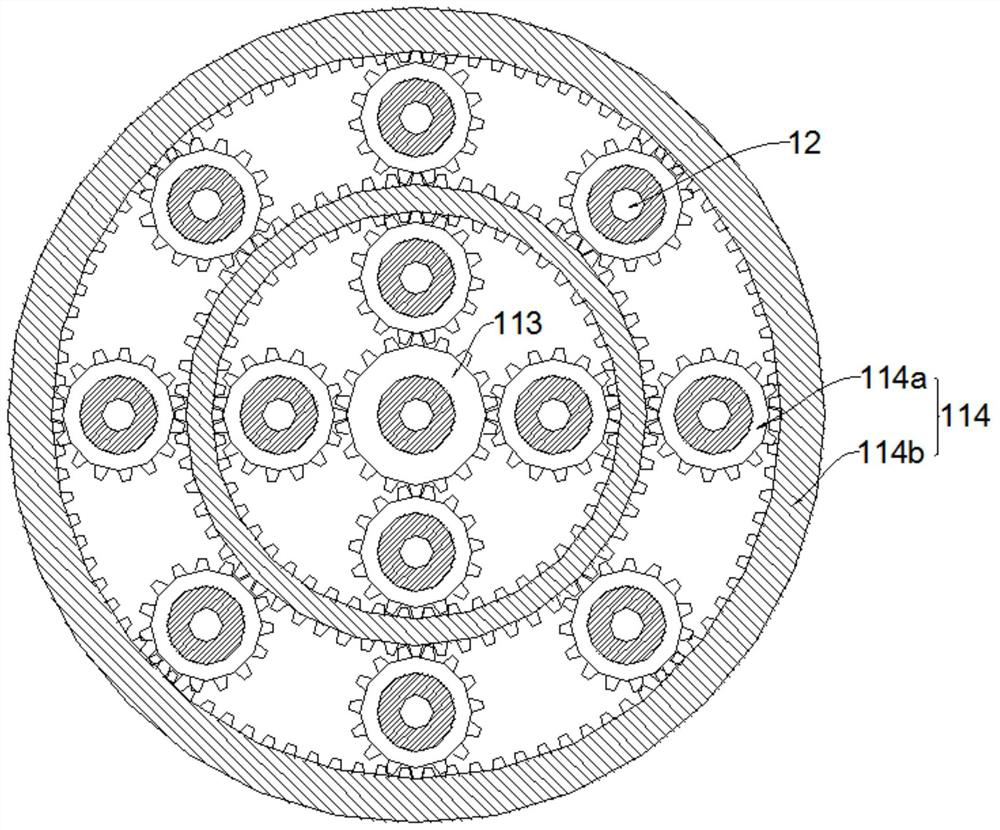

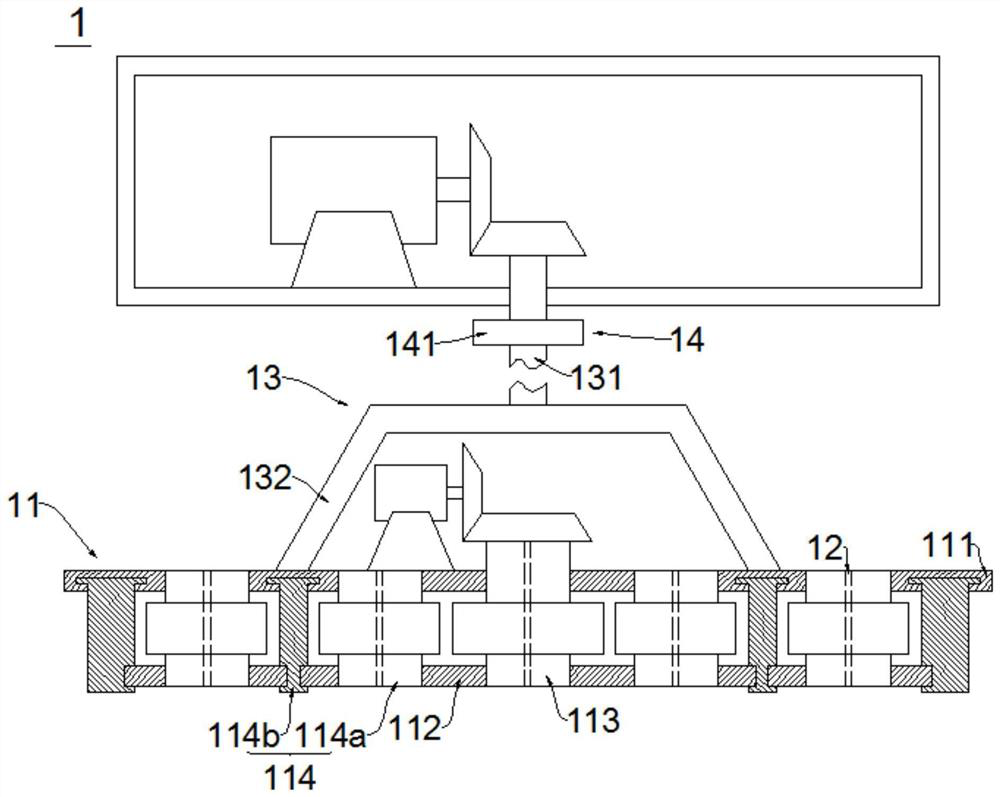

[0030] The present embodiment provides a powder wiping mechanism 1 of a wafer duster, comprising a planetary gear set 11 and a strong magnet for connecting special filter paper for dust wiping, and the strong magnet is arranged on the lower end surface of the planetary gear set 11; planetary gears are used The group 11 is used as a transmission mechanism, and a strong magnet is installed on the lower end of the planetary gear set 11 to connect the special filter paper for powder wiping, so that both parts of the special filter paper for dust wiping can realize the revolution around the center, and at the same time, some parts can realize the center around itself Self-rotation makes the powder rubbing effect better.

[0031] In this embodiment, the planetary gear set 11 includes a top plate 111, a bottom plate 112, a driving gear 113 and several planetary sets 114 that are sheathed in sequence. Group 114 includes several planetary gears 114a and ring gear 114b, and several plan...

Embodiment 2

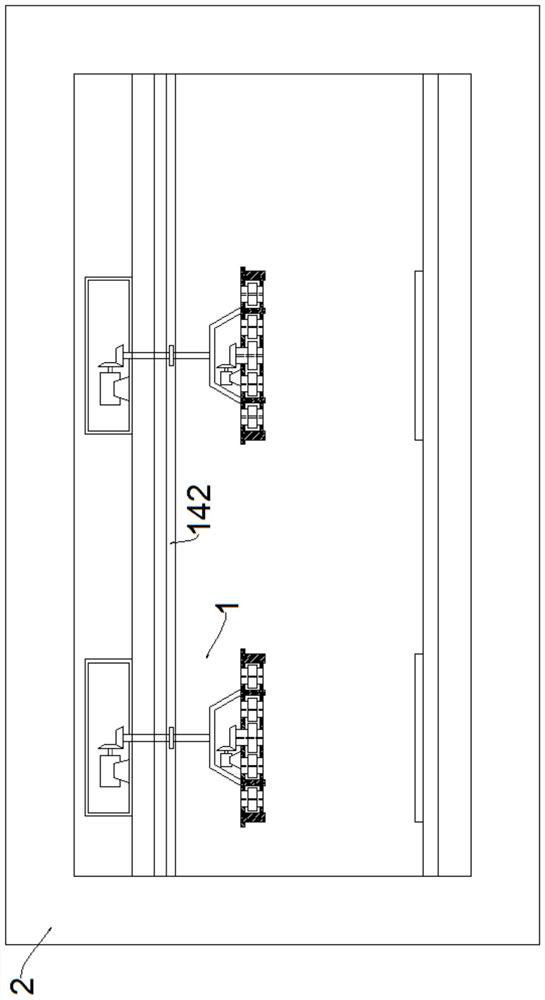

[0038] This embodiment provides a wafer wiper, including a wiper chamber 2 and a wiper mechanism 1 of the wafer wiper provided in Embodiment 1, and the wiper mechanism 1 is installed in the wiper chamber 2 . Specifically, an observation door is provided on one side of the powder wiping bin 2, and a dust collection tank is provided below the observation door.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com