Water plugging method and device for gushing water in gap of steel sheet pile cofferdam

A technology of steel sheet pile cofferdam and steel sheet pile, applied in sheet pile wall, building, infrastructure engineering and other directions, can solve the problems of normal construction of cofferdam, waste of resources, high cost of water blocking, and achieve novel structure and design, ensure the The effect of smooth operation and low cost of water blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

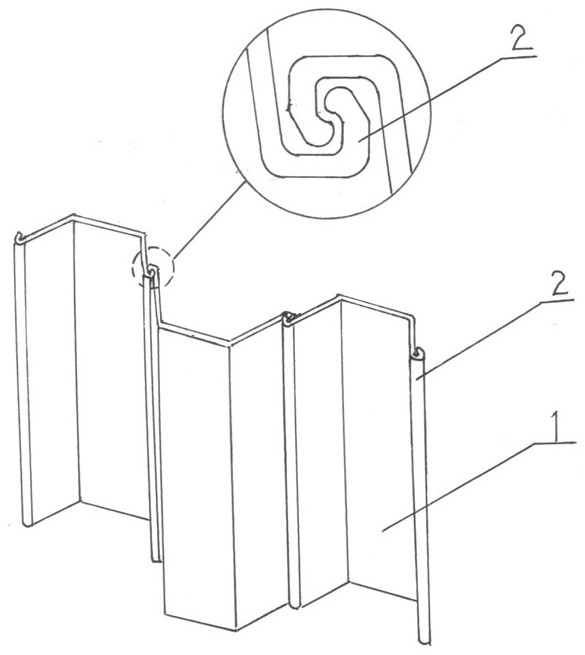

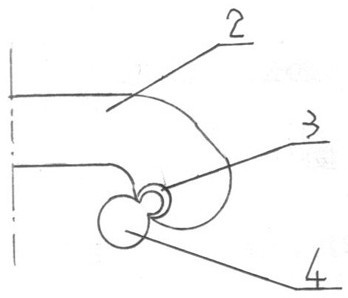

[0047] Embodiment 1: as Figure 1 to Figure 6 As shown, the gap inflatable water blocking structure is composed of a groove 3 and an inflatable bag 4. The groove 3 is longitudinally arranged at the lock 2 where the steel sheet pile 1 is docked, and an inflatable bag 4 is arranged in the groove. Air bag to prevent damage to the air bag when planting piles.

[0048] The upper and lower ends of the groove are set at a distance from the upper and lower ends of the steel sheet pile 1, that is, the upper and lower ends of the groove are 5-10cm away from the upper and lower ends of the steel sheet pile, respectively, to prevent damage during pile planting. inflatable bag.

[0049] The opening end of the groove is located on the corresponding steel sheet pile surface, and can be located on the steel sheet pile surface at the buckle 2 on any side. The test shows that the diameter of the inflatable bag after expansion is 2-8cm, which can effectively seal the leakage of the gap at the ...

Embodiment 2

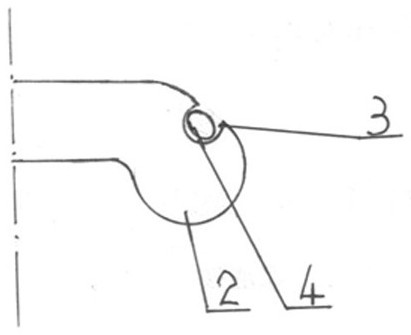

[0054] Embodiment 2: as Figure 7 and Figure 8 As shown, different from Embodiment 1, the gap inflatable water blocking structure may not be provided with grooves, but only consists of the air bag 4, or only a shallow semicircular groove is provided according to the thickness of the air bag and the protective layer 7, The inflatable bag is longitudinally arranged at the buckle 2 of the steel sheet pile, or in the shallow semicircular groove there. One end of the inflatable bag is provided with an air injection port 6 , and the outer end of the inflatable bag 4 is provided with a protective layer 7 . The protective layer 7 is made of wear-resistant and extrusion-resistant synthetic thin plastic film, such as PE, PPS, PPSU, etc.; the inner ends of both sides of the protective layer are provided with an adhesive layer 8 that fits with the corresponding steel sheet pile surface. That is, the adhesive layer passing through the two sides of the protective layer of the inflatable b...

Embodiment 3

[0056] Embodiment 3: as Figure 9 As shown, the difference from Example 2 is that the gap inflatable water blocking structure is an expansion bag, and the expansion bag is longitudinally arranged at the lock of the steel sheet pile, and the outer end surface 10 of the expansion bag is made of a wear-resistant and extrusion-resistant synthetic thin plastic film. The inner end surface 9 of the expansion bag is made of elastic material or made of wear-resistant and extrusion-resistant synthetic thin plastic film. The four sides of the inner and outer end surfaces of the expansion bag are sealed together to form an expansion bag of the hollow part, and one end of the expansion bag is provided with an injection port to communicate with the hollow part. The outside of the inner end surface of the expansion bag is provided with an adhesive layer 8 that is bonded to the steel sheet pile surface, and the outer end surface of the adhesive layer is provided with an anti-adhesive film lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com