Composite spring damping adjustable vibration isolator

A compound spring and adjustable technology, which is applied in the direction of spring/shock absorber, spring, spring assembly composed of several springs, etc., can solve the problems of small application range, unstable performance, poor vibration isolation effect, etc., to achieve The effect of improving performance stability, improving performance stability and strong impact resistance, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

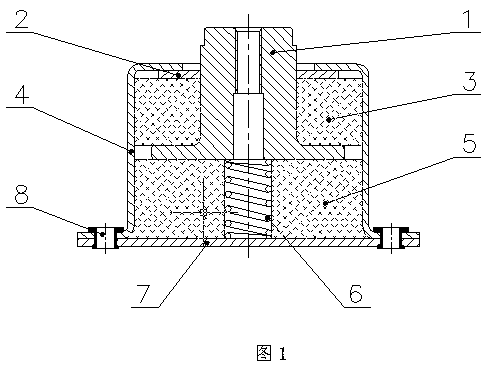

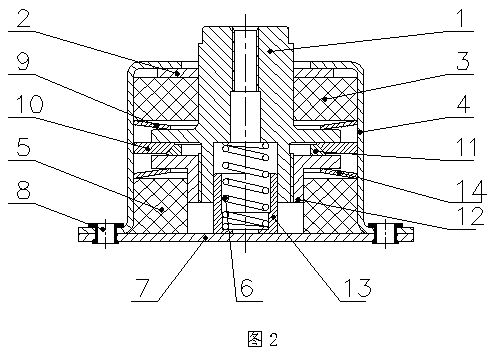

[0014] The present invention will be further described below in conjunction with the drawings.

[0015] Such as figure 2 As shown, the compound spring damping adjustable vibration isolator includes a connecting shaft 1, a baffle 2, an upper wire mesh pad 3, a shell 4, a lower wire mesh pad 5, a spiral spring 6, a bottom plate 7, a hollow rivet 8, and a second A disc spring 9, an opening and closing ring 10, a conical ring 11, an adjusting screw sleeve 12, a bushing 13, and a second disc spring 14. Between the upper part of the shoulder of the connecting shaft 1 and the housing 4, a baffle 2, an upper wire mesh pad 3 and a first disc spring 9 are sequentially installed from top to bottom, and the lower part of the shoulder of the connecting shaft 1 is from top to bottom. The opening and closing ring 10, the conical ring 11, the adjusting screw sleeve 12, the second disc spring 14 and the lower wire mesh pad 5 are arranged in sequence. The inner hole of the lower end of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com