Split type mechanical sealing part of elastic sealing ring with rectangular cross section

A rectangular cross-section, elastic sealing technology, applied in the direction of mechanical equipment, engine sealing, engine components, etc., can solve problems such as difficult connection and sealing reliability, processing costs and adverse effects of installation operations, so as to ensure the sealing effect, process and manufacture simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

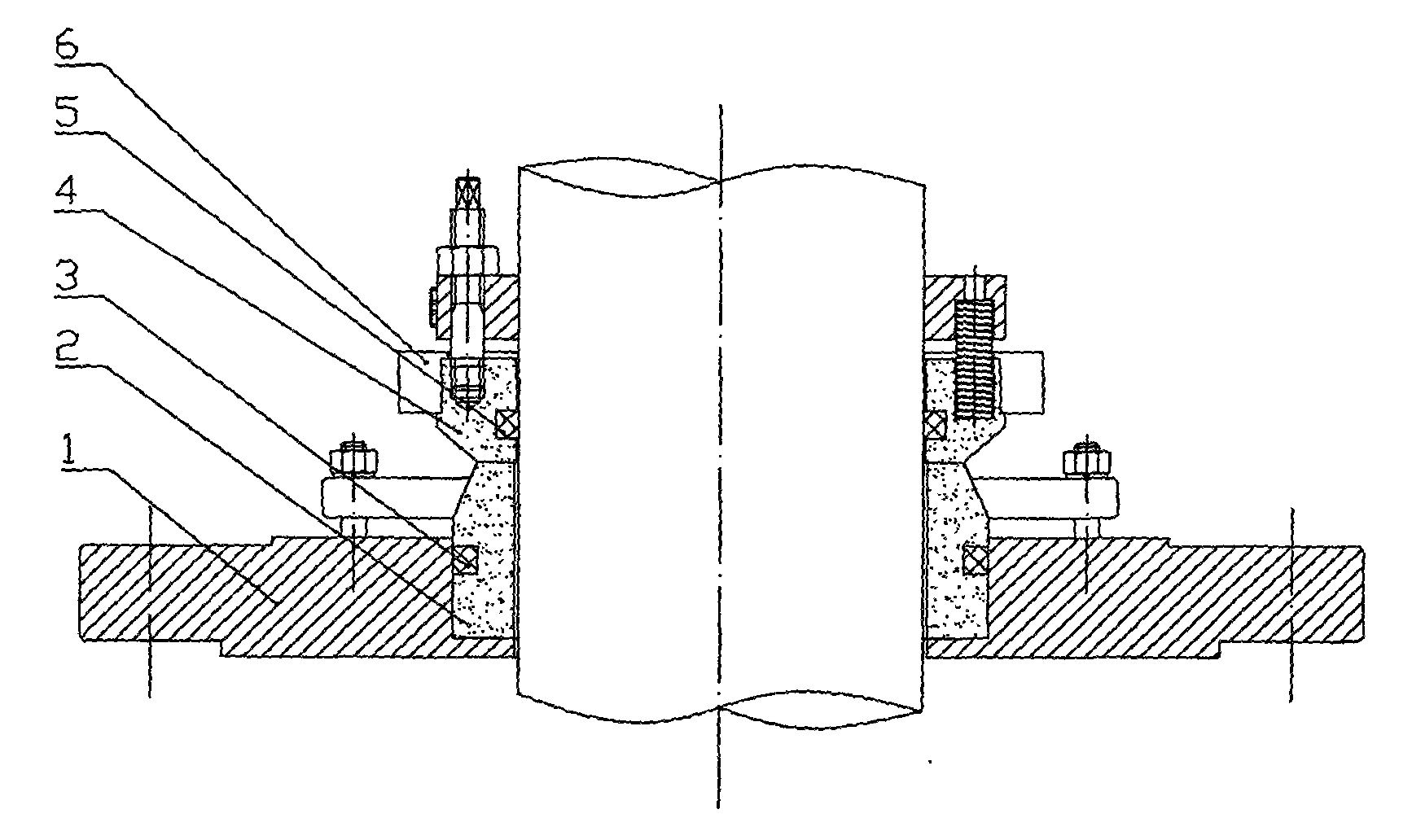

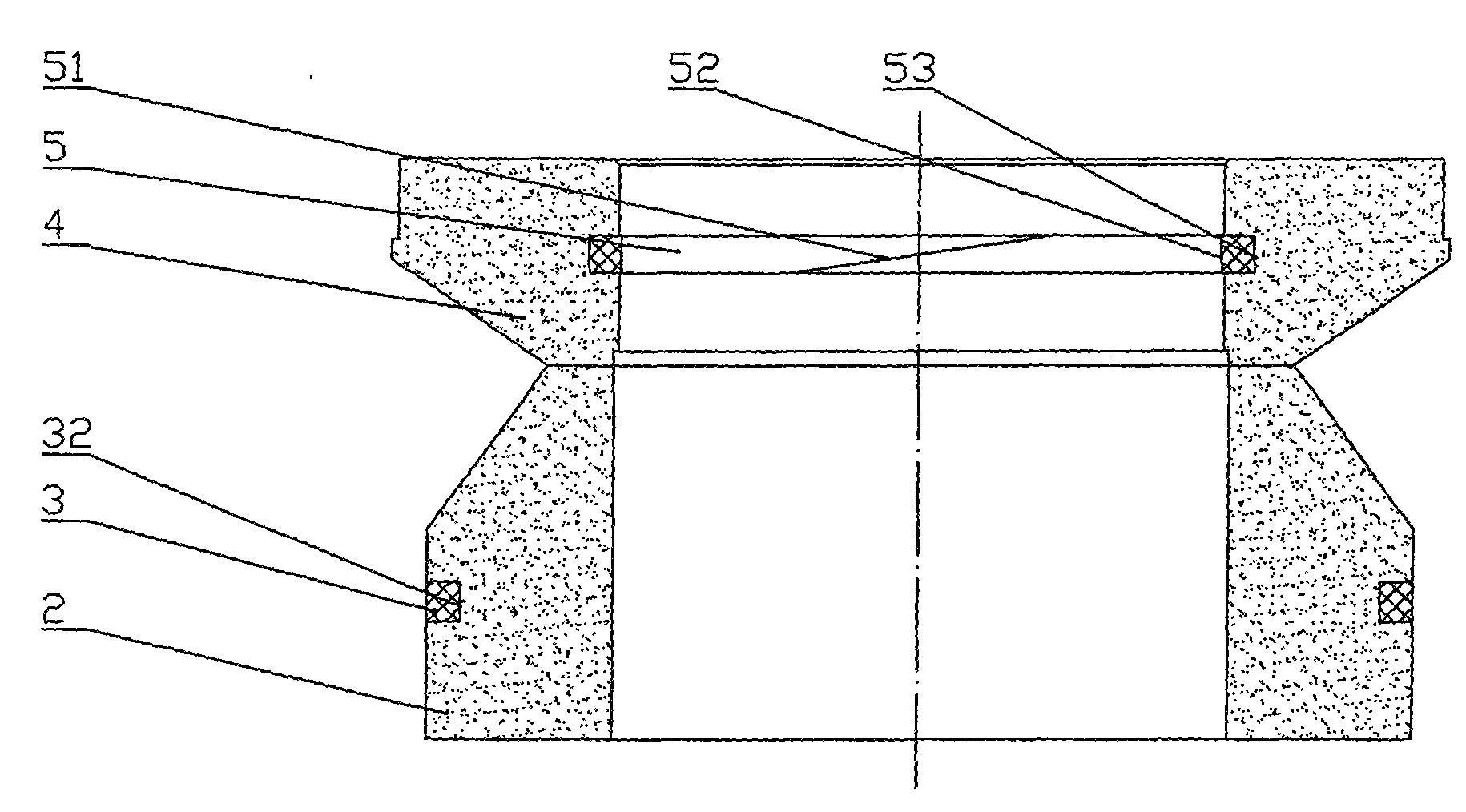

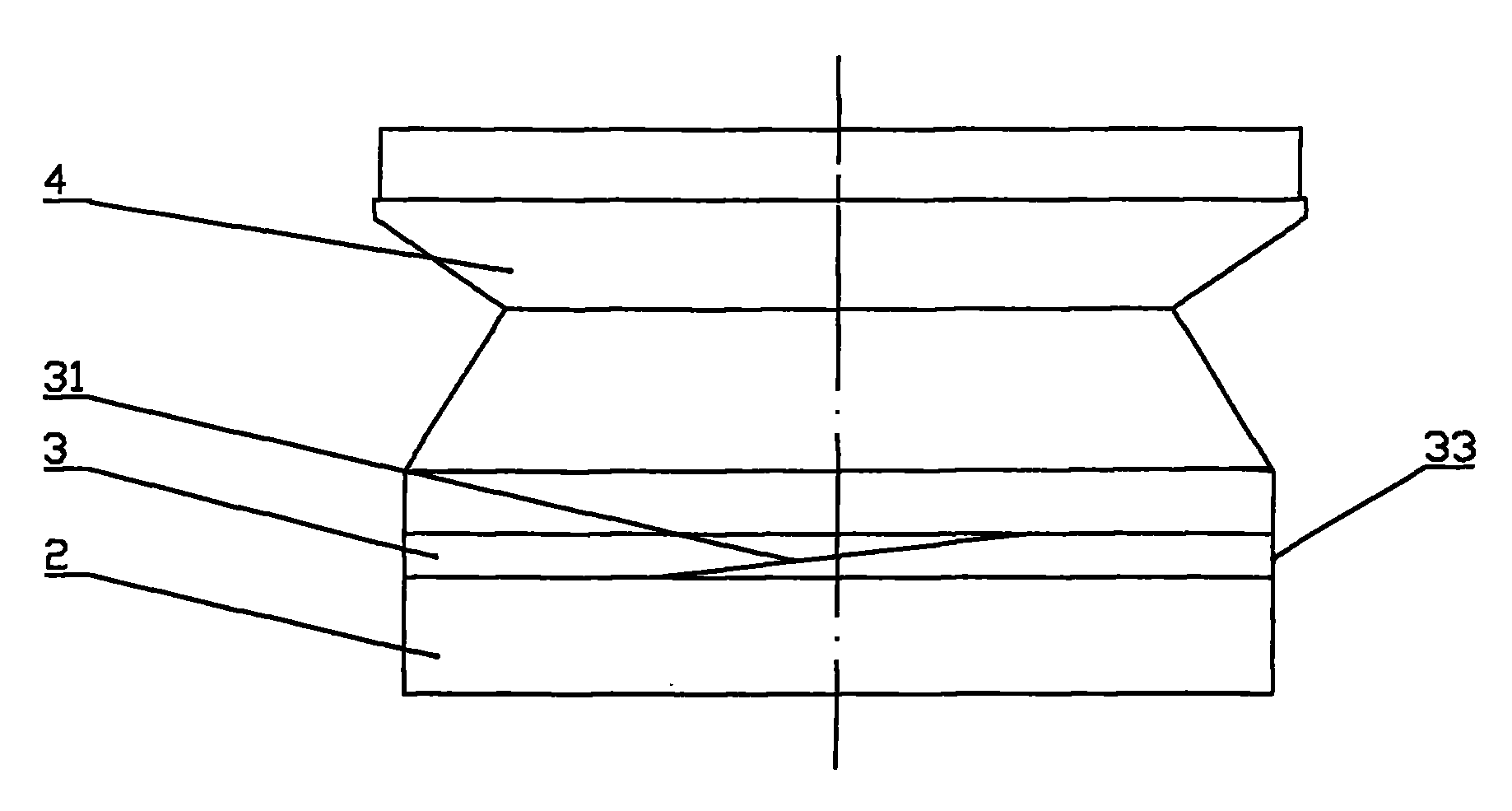

[0015] figure 1 It is an embodiment of a split mechanical seal with a rectangular cross-section elastic seal ring, in which the static ring 2 and the dynamic ring 4 are center split parts, and the static ring seal ring 3 and the dynamic ring seal ring 5 are rectangular cross-section elastic seals. The two ends are overlapped, and the thickness of the overlapping parts of the two ends of the rectangular cross-section elastic sealing strip that forms the static ring 3 and the dynamic ring 5 gradually becomes smaller toward the end, and the rectangular cross-section elastic sealing strip is perpendicular to the lapping surface The width remains the same. When replacing or installing, the two surfaces perpendicular to the overlapping surface are radially installed to form the inner cylindrical surface and the outer cylindrical surface of the static ring sealing ring 3 or the moving ring sealing ring 5 respectively. The overlapping structure overlaps in the axial direction. As far...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com