Dry-type transformer housing fixing structure

A dry-type transformer and fixed structure technology, applied in the field of transformer manufacturing, can solve the problems of inconvenient lifting and transportation, inconvenient lifting operation, waste of raw materials, etc., and achieve the effect of firm and reliable structure, simple structure and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

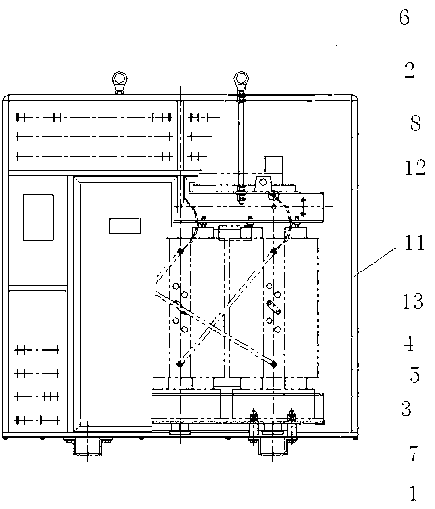

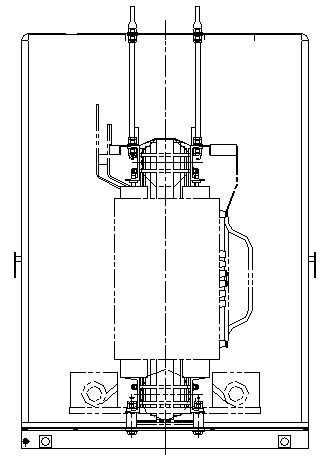

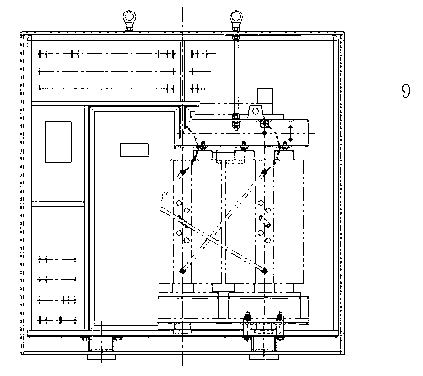

[0014] A dry-type transformer cover fixing structure, see figure 1 with figure 2 , the structure includes a trolley foot 1 arranged at the bottom of the transformer case 11 and a hanging screw 2 arranged on the upper clamp 12 of the transformer and protruding from the top of the transformer case 11. A base plate 3 is laid on the trolley foot, and a A support sleeve 5 with a bolt 4 is provided, and the position of the bolt corresponds to the position of the installation hole on the transformer lower clamp 13 ; a suspension ring 6 is provided on the top of the suspension screw 2 . There are two trolley feet, which are respectively arranged on the left and right sides of the transformer cover bottom. There are four hanging screw rods, and suspension rings are all arranged on the tops of the four hanging screw rods.

[0015] The specific assembly sequence is: place the trolley feet according to the installation gauge requirements, lay the bottom plate on the trolley feet, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com