Viscosity measurement apparatus and method

A technology of viscosity and equipment, which is applied in the field of simultaneous measurement of solution viscosity, can solve problems such as the distribution map is not given, and achieve the effect of improving the measurement of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

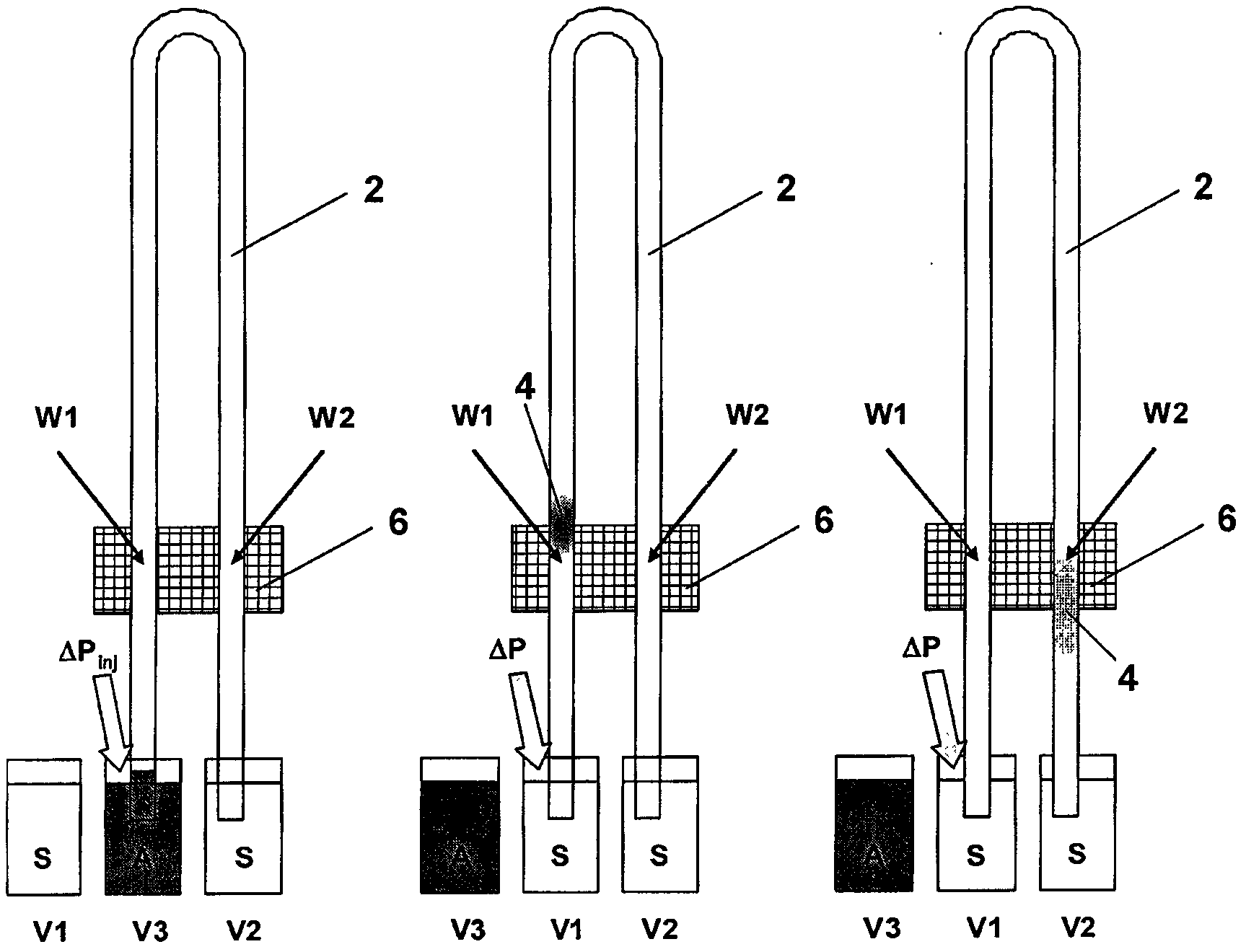

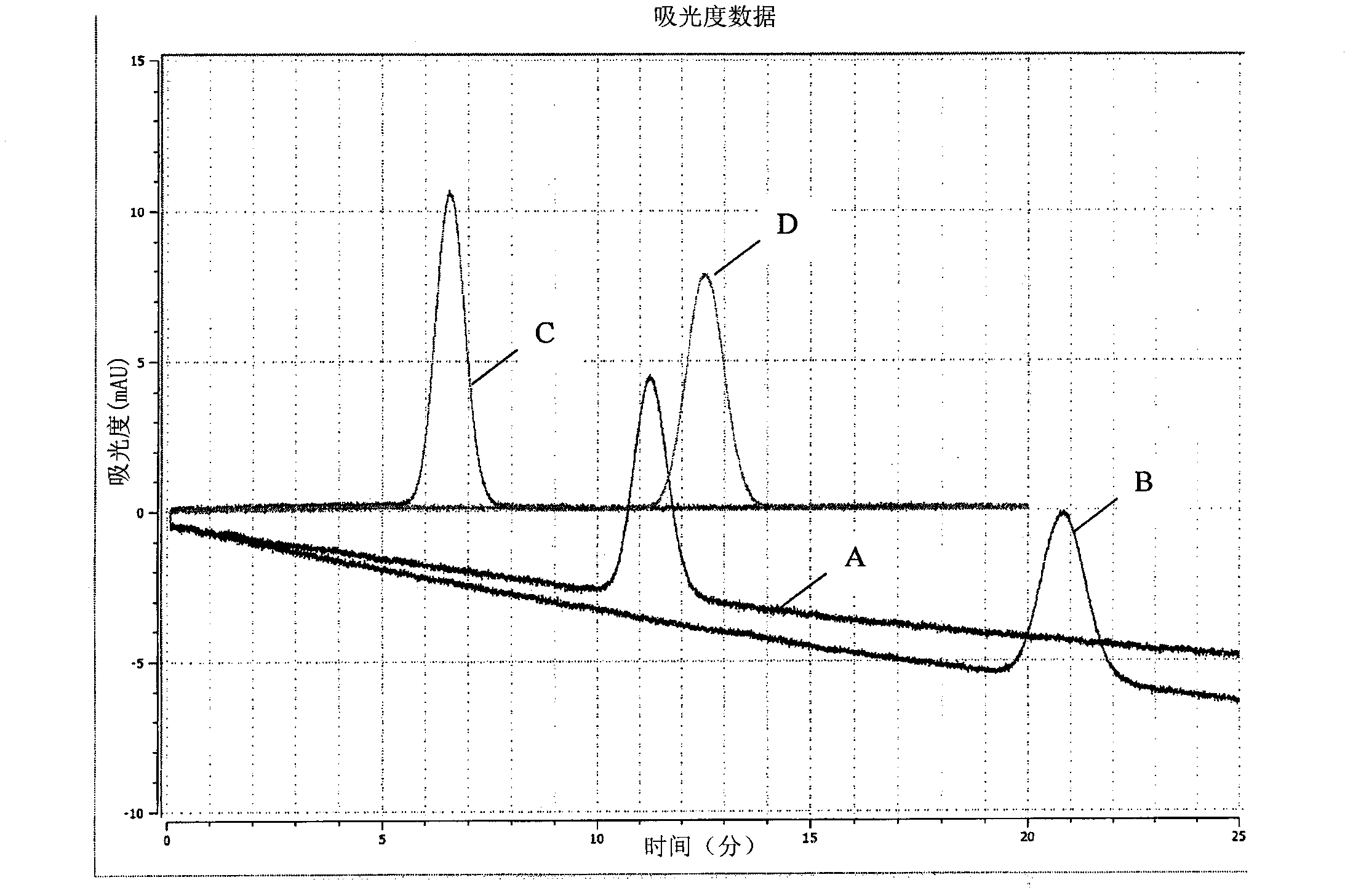

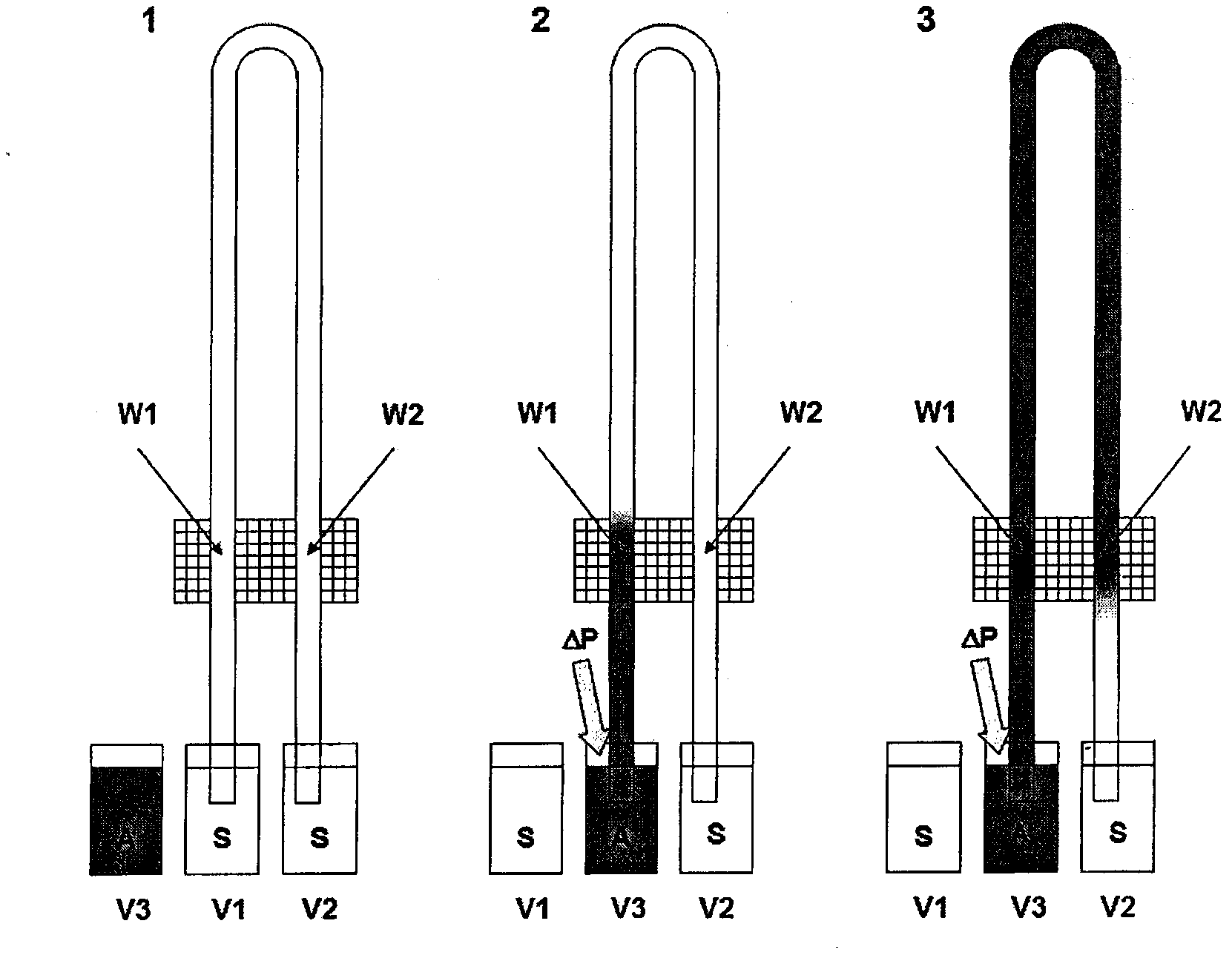

[0037] According to an embodiment of the present invention, there is provided a measurement apparatus and method which operates by driving a sample solution, solution A, through a capillary initially filled with carrier solution S at a constant pump pressure. Solution A can be injected as a pulse and followed by a continuous flow of solution S, or can be driven as a leading edge. The trend of the flow (SAS for pulse, SA for front) is imaged in two separate windows along the length of the capillary, for example using an assembly of the type described in US-7262847 including an area imager. Analyzing a series of frames as the sample pulse or sample front passes through each window can determine for each window the time to leave the window, the absorbance profile, and the change in the pulse or front. For spikes, the flow rate can also be determined. With knowledge of the length of the capillary and the position of the window, the specific viscosity of the sample solution can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com