Positioning device with double guide structure

A positioning device and double-guided technology, applied in positioning devices, manufacturing tools, clamping, etc., can solve problems such as longitudinal movement restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

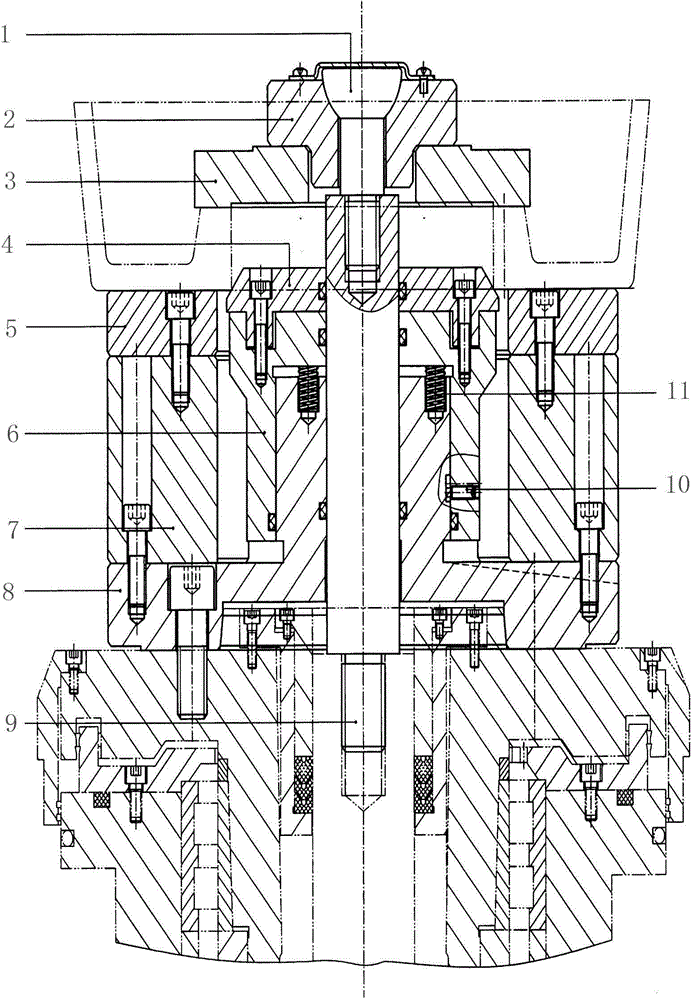

[0008] Such as figure 1 As shown, a positioning device with a double-guiding structure is connected to the shoulder of the cylindrical base 8 in sequence with a pad I7 and a pad II5. The pad I7 and the pad II5 have inner holes with equal diameters. Two The structural form of the pad is to facilitate the finishing of the upper surface of the pad II5, to ensure the levelness of the upper surface of the pad II5, and to ensure that the workpiece and the bottom surface are horizontally overlapped; the sleeve 6 is set on the top of the base 8, and is located In the inner holes of pad I7 and pad II5, the base 8 acts as a guide for the sleeve 6, and a spring 11 is provided above the base 8, and the upper end of the spring 11 is in contact with the lower surface of the cavity of the sleeve 6; The top of the cylinder 6 is connected with a conical seat 4, and the outer circumference of the conical seat 4 is provided with a conical surface, which is used for the axis positioning of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com