Five-freedom degree magnetic levitation guide rail with novel electromagnet distribution

A technology of electromagnets and degrees of freedom, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problem of mutual coupling of magnetic fields, and achieve the effect of solving mutual coupling of magnetic fields and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

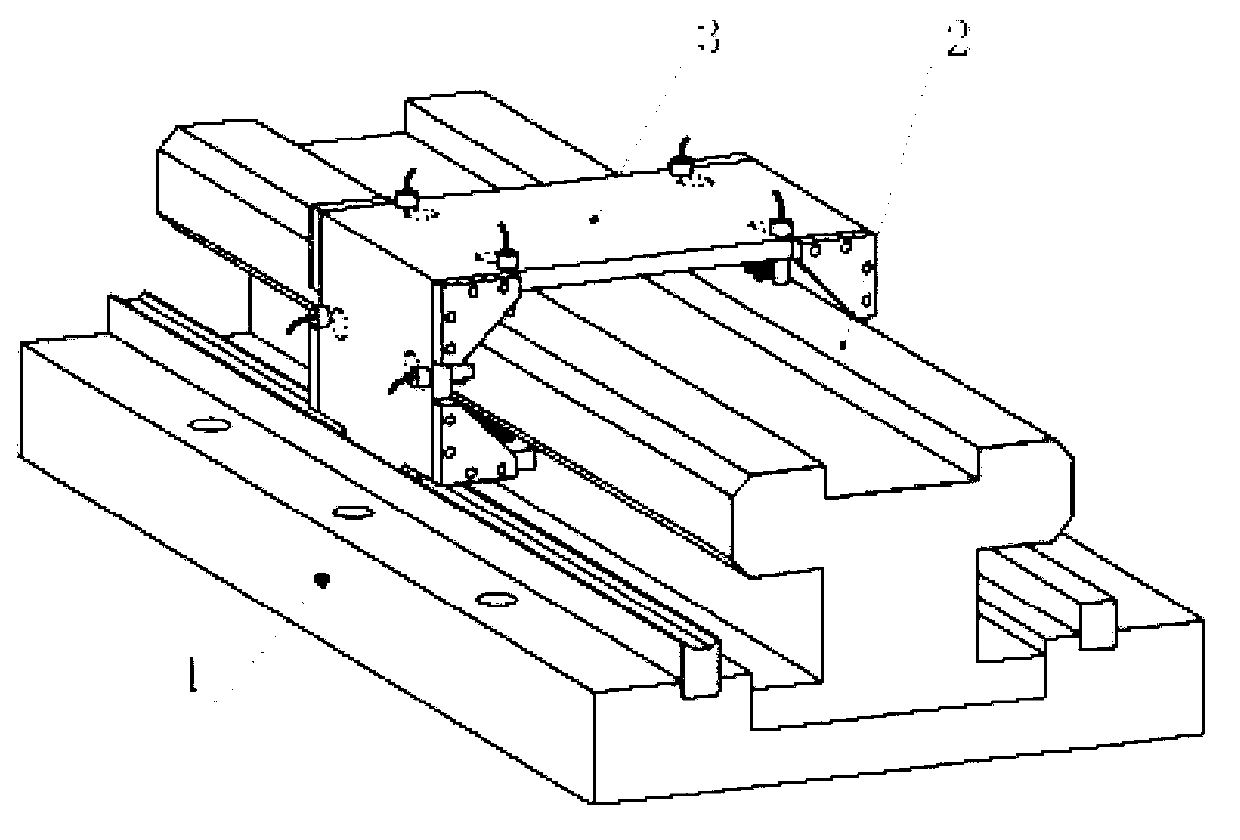

[0026] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 This embodiment will be described. The new five-degree-of-freedom maglev guide rail with electromagnet distribution described in this embodiment includes a base 1, a guide rail 2 fixed on the base 1, and a suspension platform 3 sleeved on the outside of the guide rail 2, and is set on the suspension platform 3. 12 pieces of electromagnets, and the air gap detection displacement sensor group arranged on the suspension platform 3 for detecting the motion state of the suspension platform 3 in each direction; the suspension force of the 12 pieces of electromagnets and the air gap detection displacement of the suspension platform 3 Under the feedback of the sensor group, it is stably suspended on the guide rail 2 (in the form of wrapping the guide rail 2).

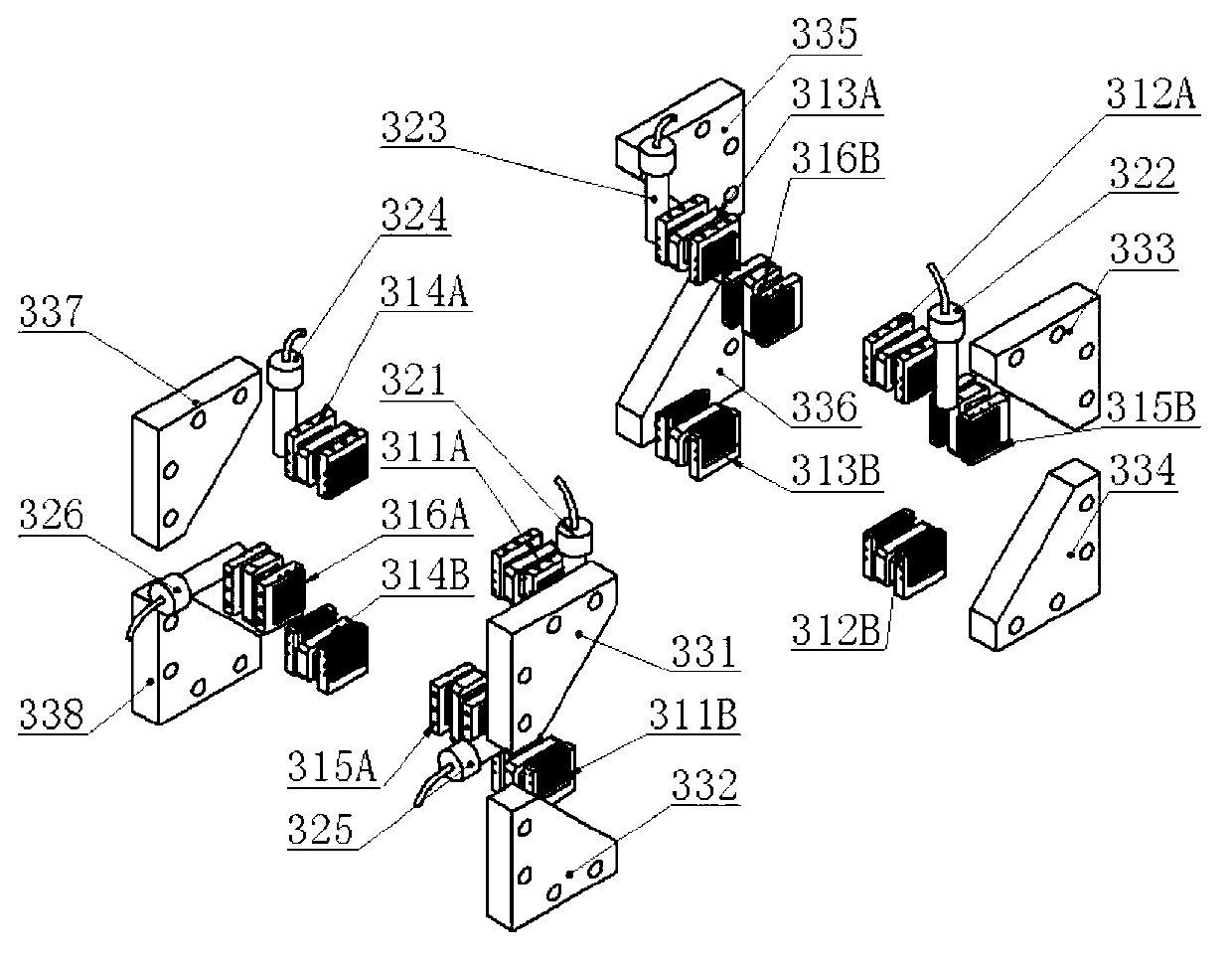

[0027] The 12 electromagnets providing five-degree-of-freedom suspension include: the first electromagnet 311A and the second ...

specific Embodiment approach 2

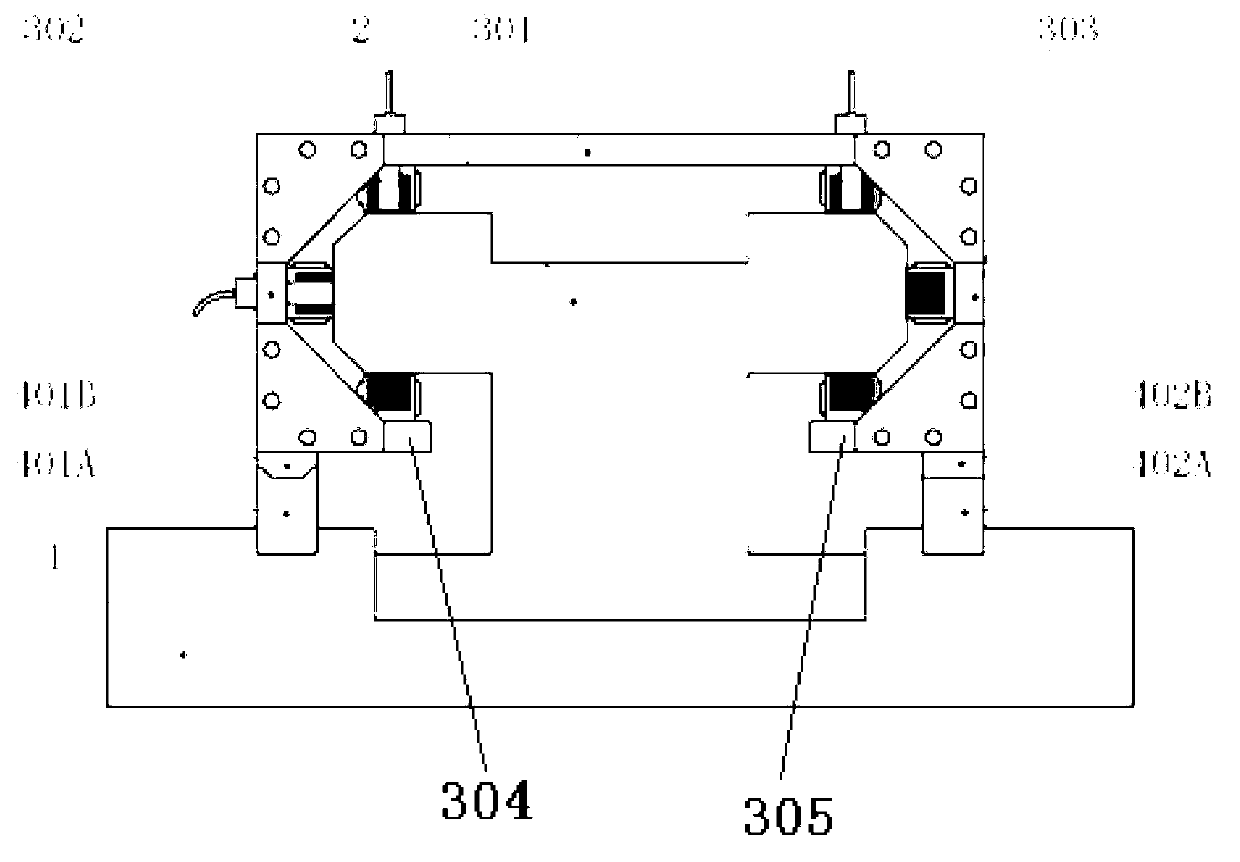

[0029] Specific implementation mode two: combination image 3 and Figure 4 This embodiment will be described. The suspended platform 3 includes an upper support plate 301 connected by corresponding connecting plates 331, 332, 333, 334, 335, 336, 337, 338, a left support plate 302 fixed on the left end of the upper support plate 301, a fixed support plate The right side support plate 303 at the right end of the upper support plate 301, the left side lower support plate 304 that is located below the upper support plate 301 and fixed on the free end of the left support plate 302, and the lower support plate 304 that is located under the upper support plate 301 and is fixed on the left side support plate 301. The right lower support plate 305 at the free end of the right support plate 303 is perpendicular to each other between two adjacent support plates.

[0030] The first electromagnet 311A, the third electromagnet 312A, the fifth electromagnet 313A and the seventh electromagne...

specific Embodiment approach 3

[0032] Specific implementation mode three: combination Figure 5 This embodiment will be described. Figure 5 It is the structural diagram of each electromagnet described in the present invention, all electromagnets all adopt U-shaped structure, and the iron core adopts silicon steel sheet 341 to superimpose and form, close to cooling pipe 344 on both sides of copper winding 343, fixing piece 342 will electromagnet It is fixed on each support plate of the suspension platform 33.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap