Horizontally-arranged periodic blow-down flash tank

A technology of regular sewage discharge and container expansion, which is applied in the direction of boiler cleaning equipment, etc., can solve problems such as equipment shell erosion, achieve the effect of prolonging service life and avoiding direct erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

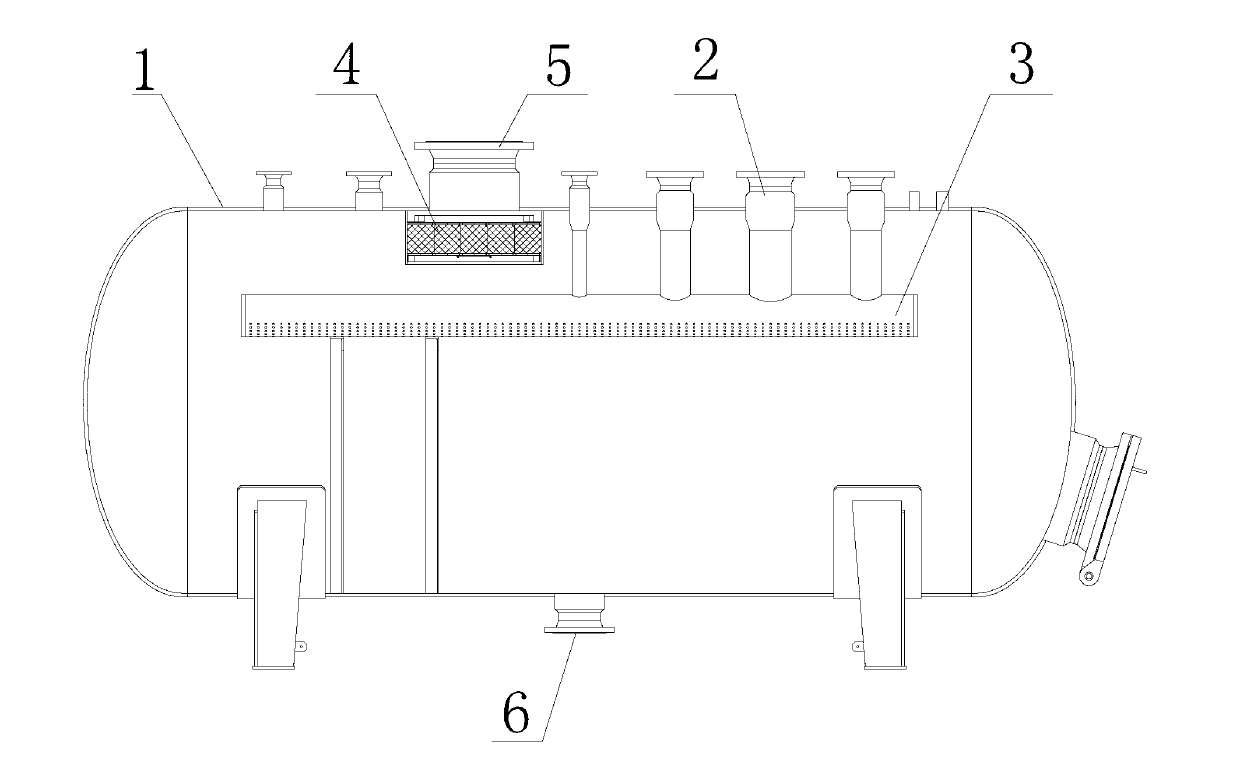

[0016] Such as figure 1 As shown, a horizontal periodic sewage discharge expansion container has a shell 1, a sewage inlet pipe 2 is installed on the top of the shell 1, the top opening of the sewage water intake pipe 2 is the boiler periodic sewage discharge inlet, and the bottom of the shell 1 has a sewage discharge port 6 The inner cavity of the housing 1 is equipped with a spray energy dissipation device, the bottom opening of the sewage inlet pipe 2 communicates with the inlet of the spray energy dissipation device, and the top of the housing 1 is provided with a secondary steam discharge port 5 .

[0017] The spray energy dissipating device has a spray pipe 3, the bottom opening of the sewage inlet pipe 2 communicates with the top opening of the spray pipe 3, and the bottom of the spray pipe 3 is provided with a plurality of evenly arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com