A kind of coal-water slurry gasifier vault

A technology of gasifier and coal-water slurry, which is applied in the field of coal-water slurry gasifier device, can solve problems such as arch refractory brick scour, threat to gasifier safe operation, and impact on gasifier benefit, so as to reduce scour, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

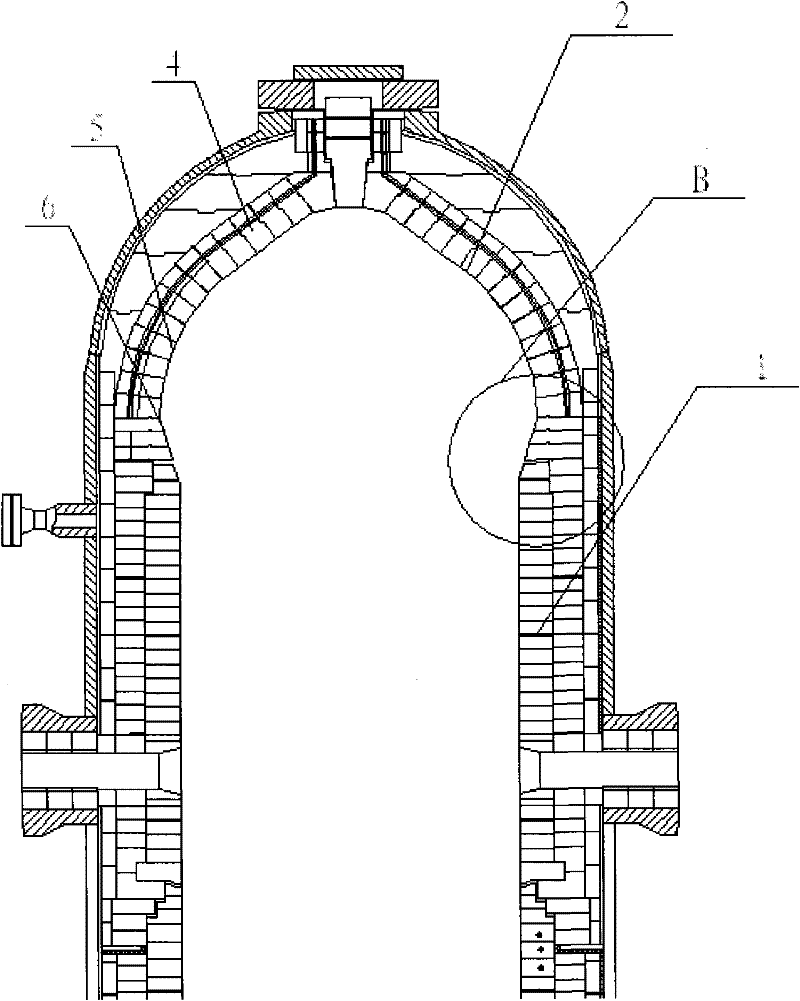

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

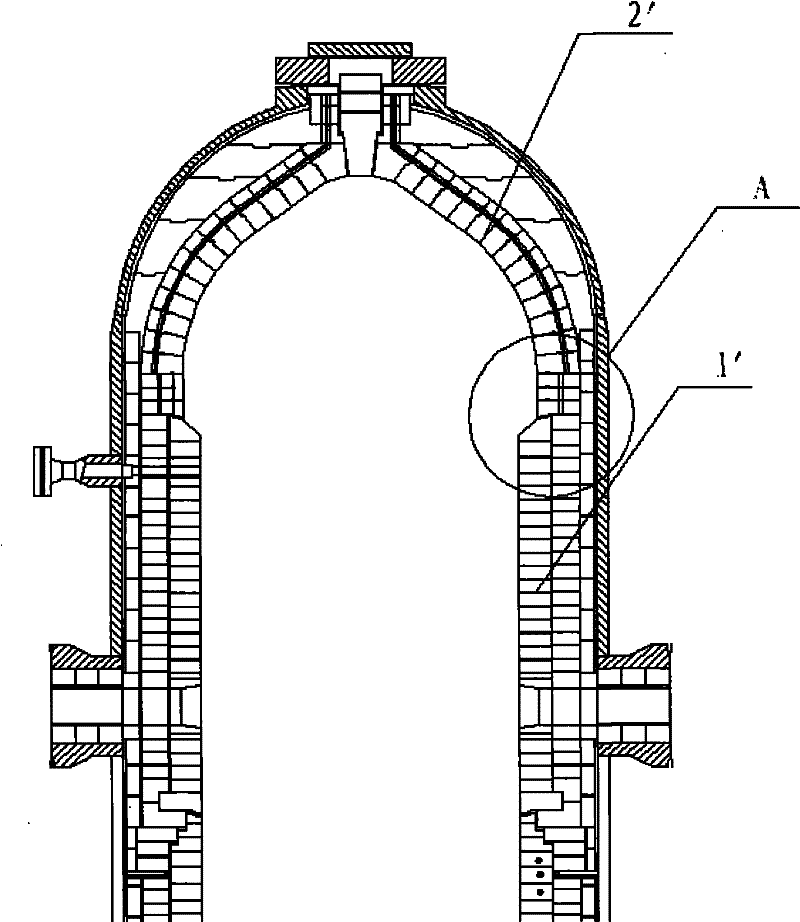

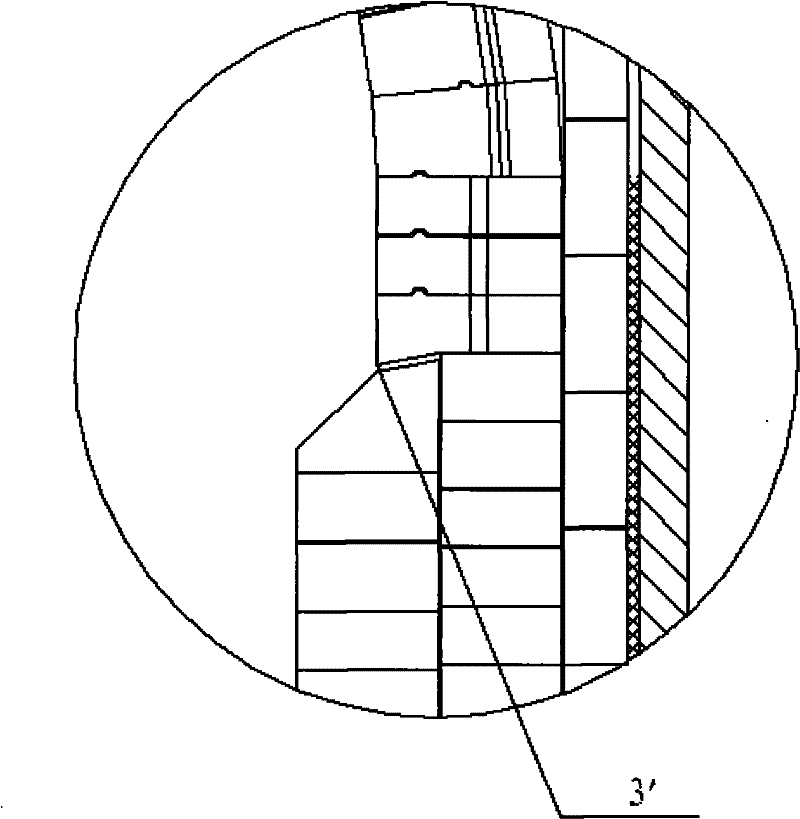

[0013] see image 3 , Figure 4 , the present invention includes a cylinder 1, a vault 2, an expansion joint 3, a conical top 4, a spherical middle part 5, and an inverted conical lower end 6. The expansion joint 3 is set at the connection between the cylinder 1 and the vault 2, so The upper half of the vault 2 is a space enclosed by a conical top 4 and a spherical middle part 5 tangentially, and the lower end near the expansion joint 3 is in an inverted conical shape, and the lower end 6 of the inverted conical shape is opposite to the expansion joint 3 in position. correspond. With this structure, the flow direction of the high-speed airflow is firstly adjusted at the inverted cone transition, avoiding the direct erosion of the expansion joint 3 by the high-speed airflow, meeting the configuration requirements of the airflow fiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com