Insole backpart longitudinal stiffness testing method

A technology of longitudinal stiffness and detection methods, applied in the direction of measuring devices, strength characteristics, measuring devices of feet or shoe lasts, etc., can solve problems such as system errors, rejections, errors, etc., to reduce deviations, improve differences, be scientific and accurate The effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

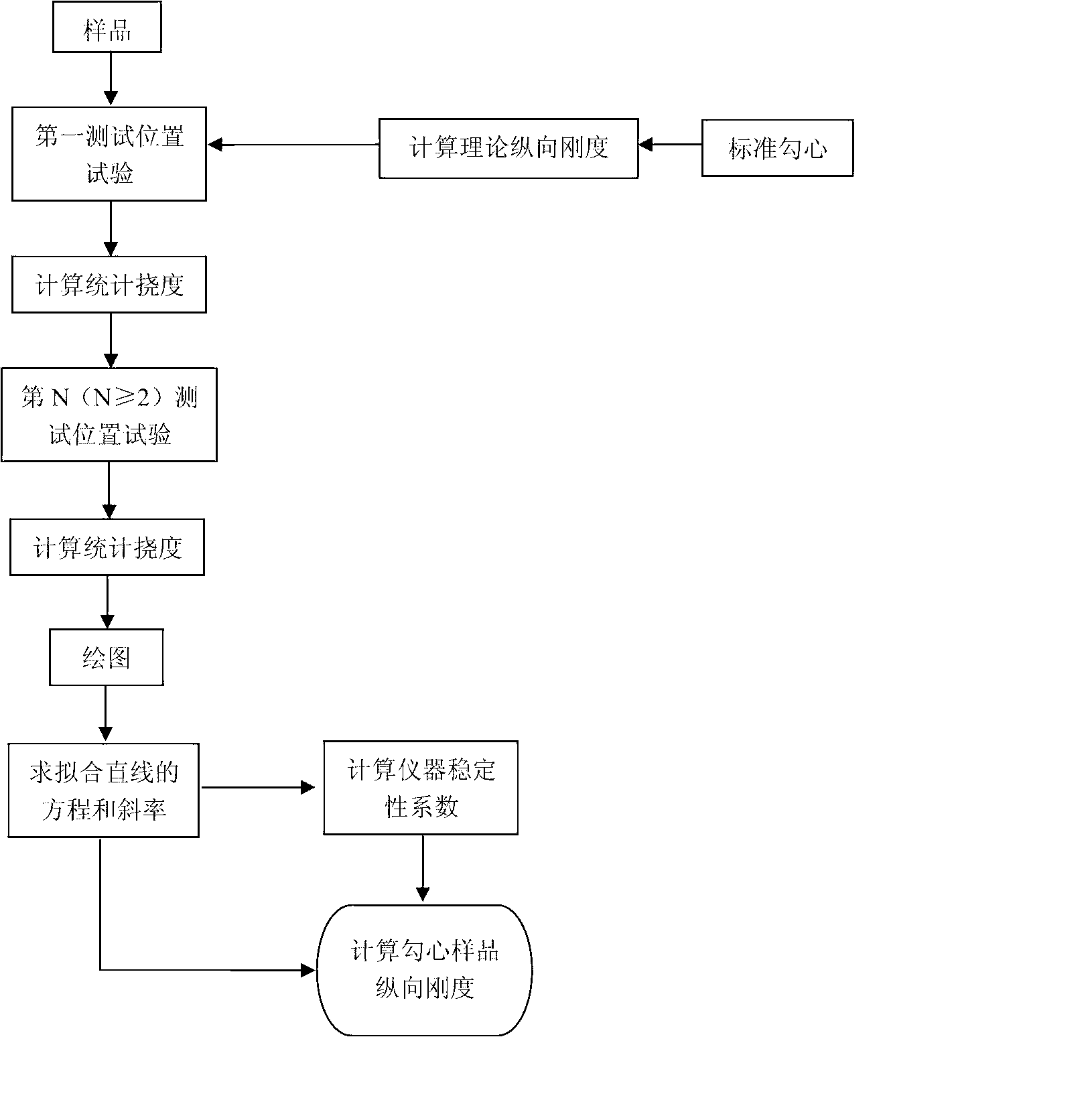

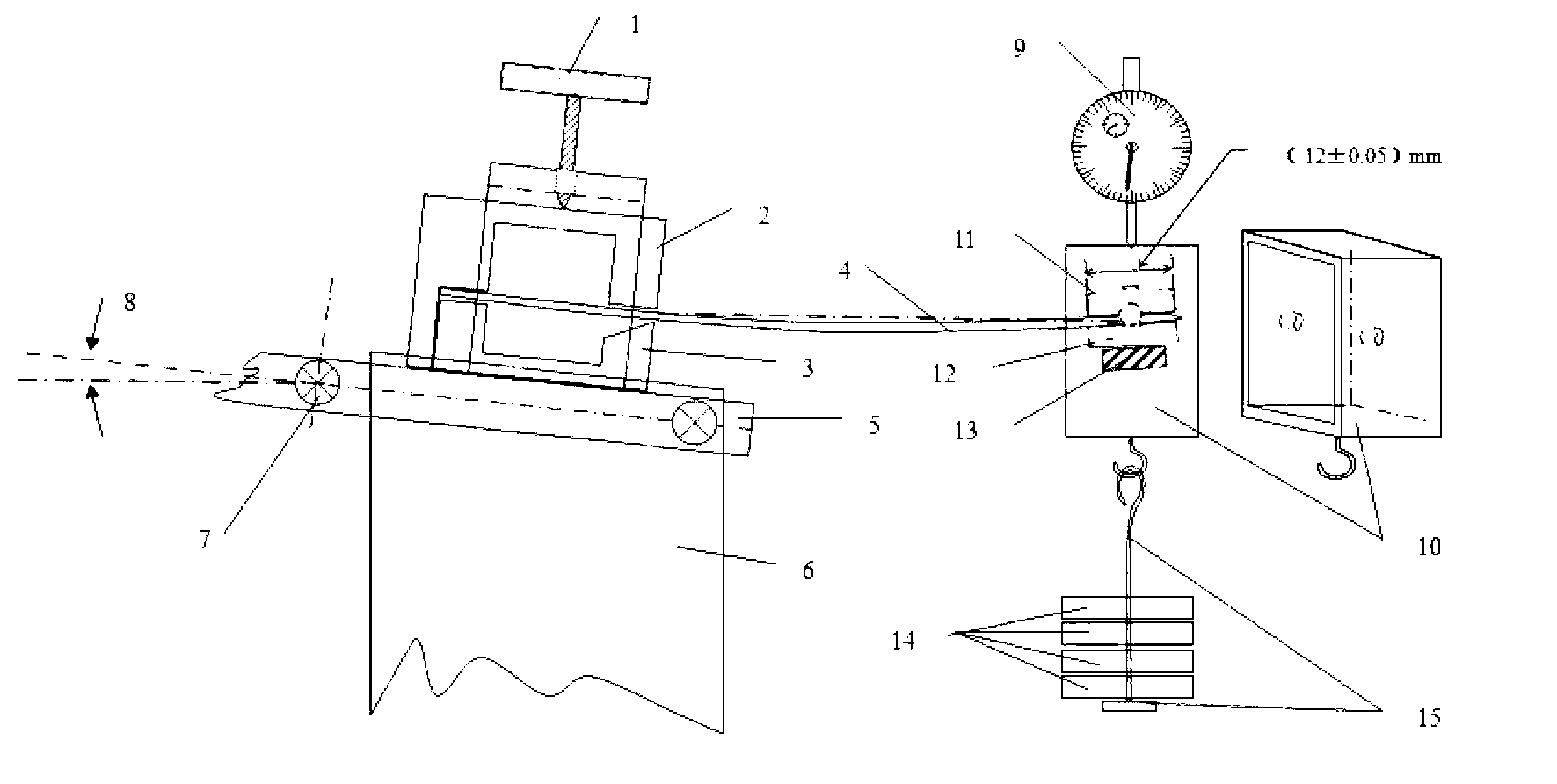

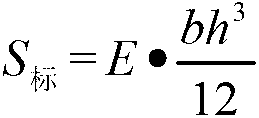

[0046] see figure 1 and figure 2 The present invention provides a method for detecting the longitudinal stiffness of the shank, so that the detection result can reflect the bending resistance characteristics of the shank as truly as possible; the detection result is not affected by the test position and the test instrument as much as possible. Such as figure 1 The shank longitudinal stiffness detection method of the present invention comprises the following steps:

[0047] Perform multiple loading tests at the first test position of the shank sample, measure the moment arm of the shank sample at the first test position and the deflection of the shank sample after each loading, and calculate the statistics of the first test position deflection;

[0048] In the same way, N (N ≥ 2) tests are carried out at different positions of the shank sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com