Tube discharging mechanism of tube bender

A pipe bending machine and pipe blank technology, which is applied in the field of pipe releasing mechanism, can solve the problems of low production efficiency, inability to meet large-scale production needs, and lack of continuity in processing, so as to achieve high pipe bending efficiency and meet large-scale production effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Next, it will be placed in the whole system to further describe the present invention, so as to better understand the purpose of the present invention.

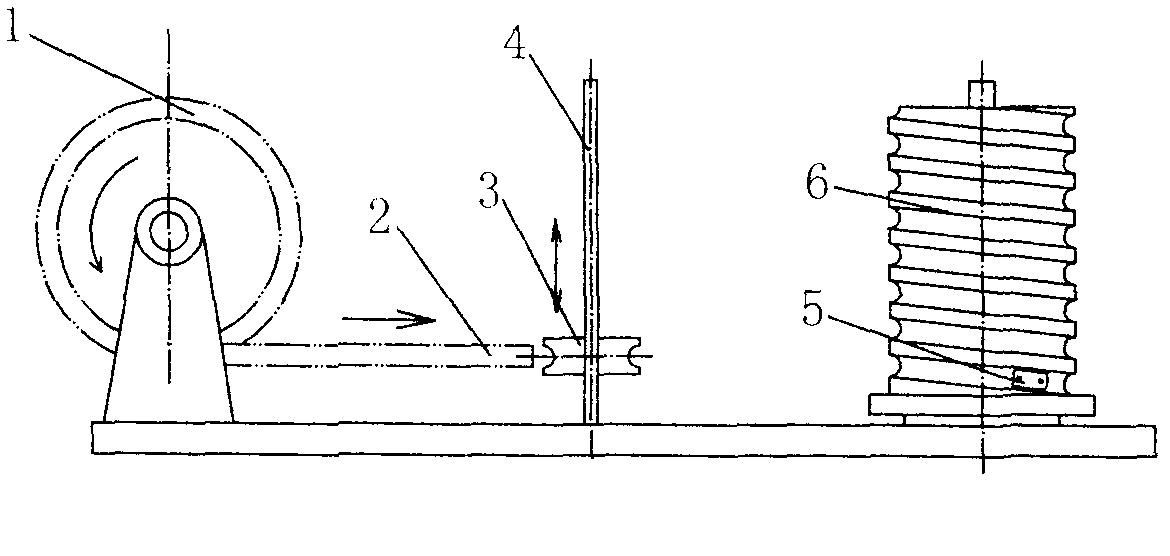

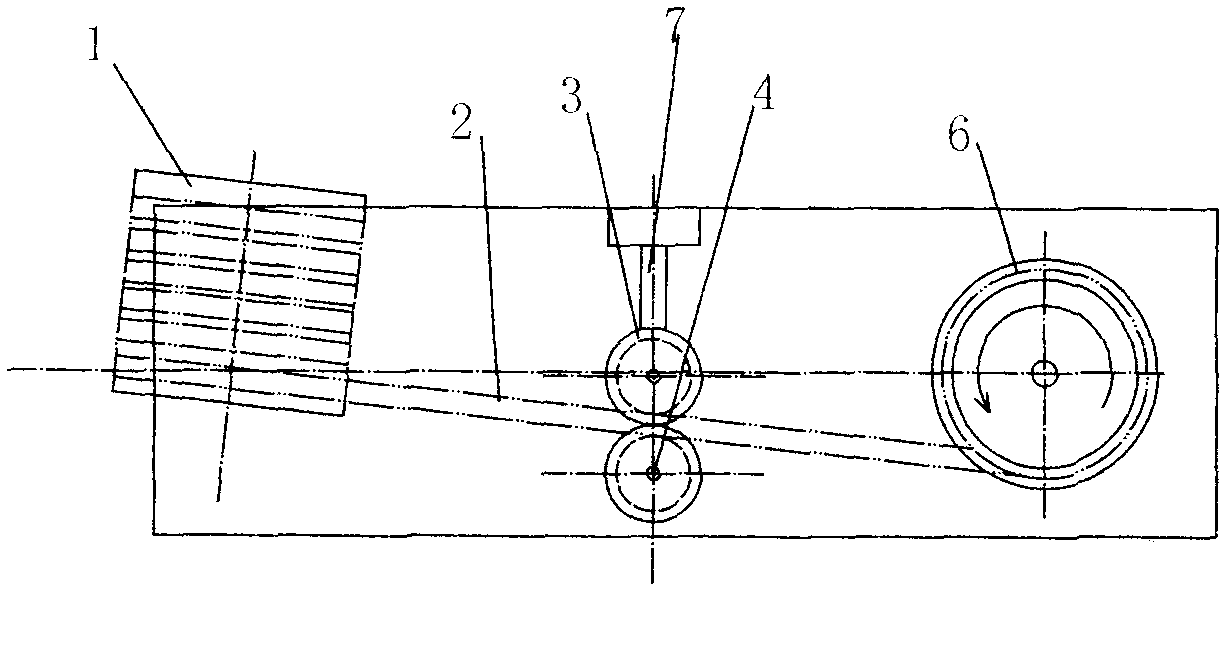

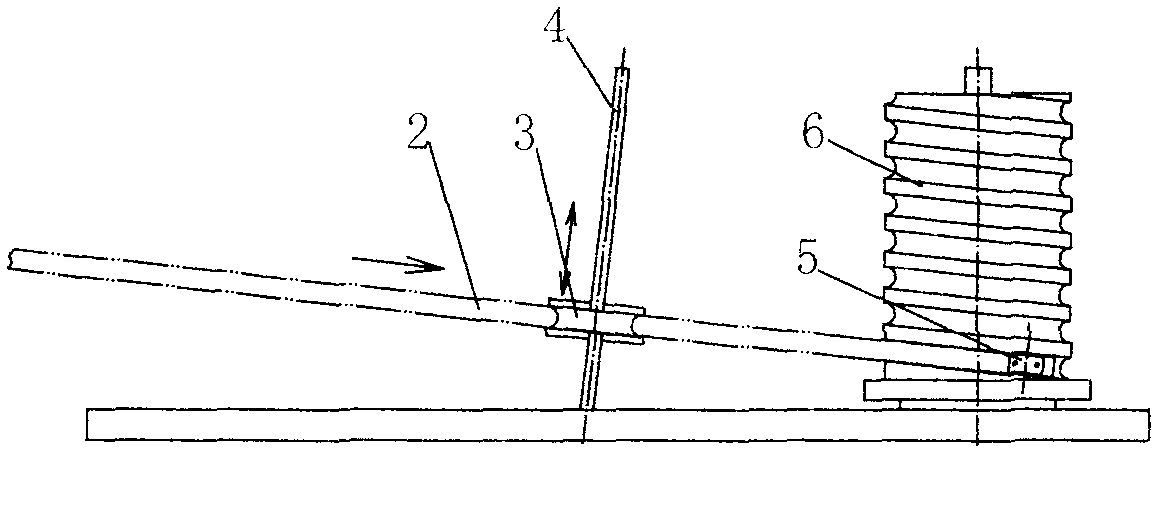

[0016] The present invention includes a frame, a pipe delivery mechanism and a pipe bending mechanism 6 arranged on the frame; wherein the pipe delivery mechanism 6 includes a delivery mechanism 1 and a pipe discharge mechanism arranged between the delivery mechanism 1 and the bending mechanism 6, The pipe release mechanism includes a shaft 4 vertically arranged on the frame, and a roller 3 that can move up and down along the shaft 4 is sleeved on the shaft 4. The roller 3 is provided with an annular concave surface that cooperates with the tube blank 2; The mechanism 6 includes a rotating cylinder, the outer circumference of which is processed into a spiral groove corresponding to the tube blank 2, the lower end of the bending mechanism 6 is provided with a clamp 5 for fixing the end of the tube blank 2; the roller 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com