A cylinder end face automatic deburring machine

A deburring machine and deburring technology, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of low work efficiency, high cost, poor deburring effect, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

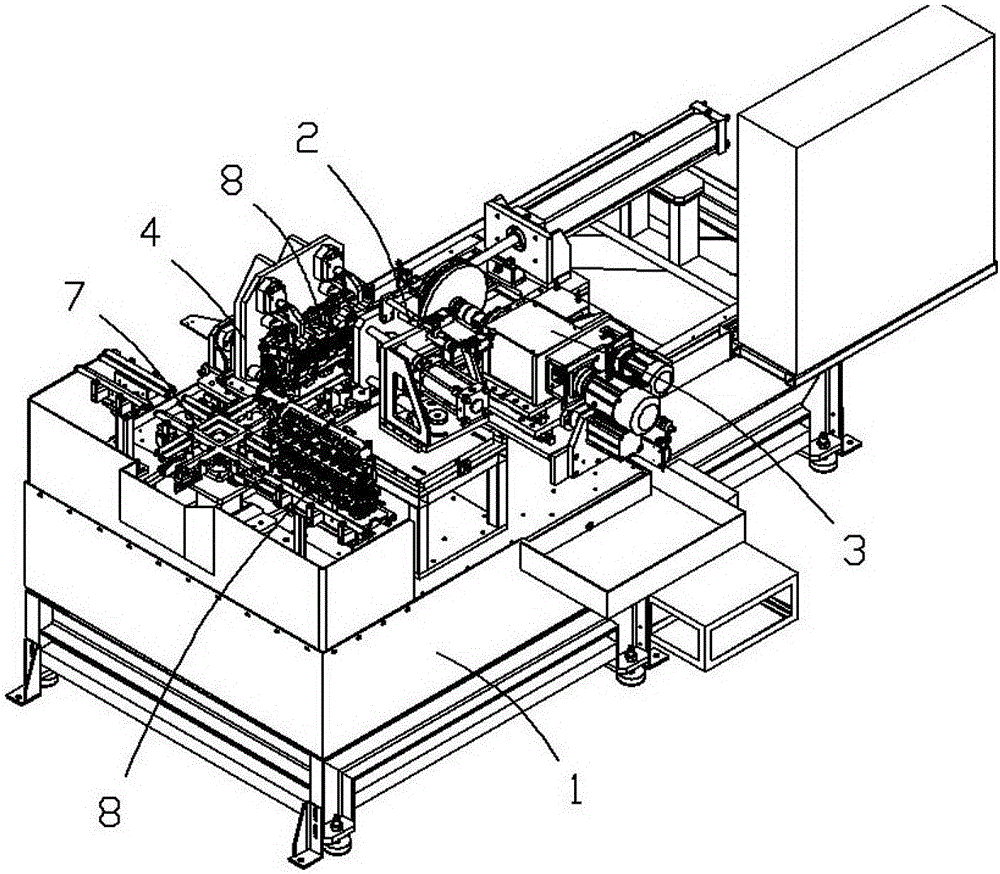

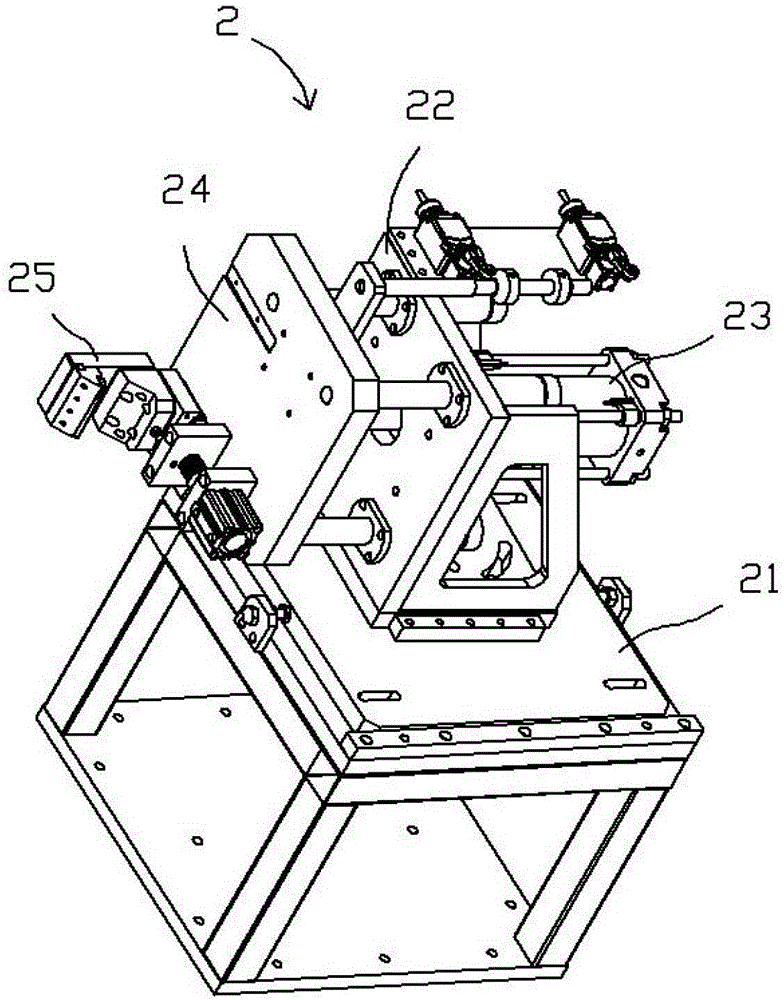

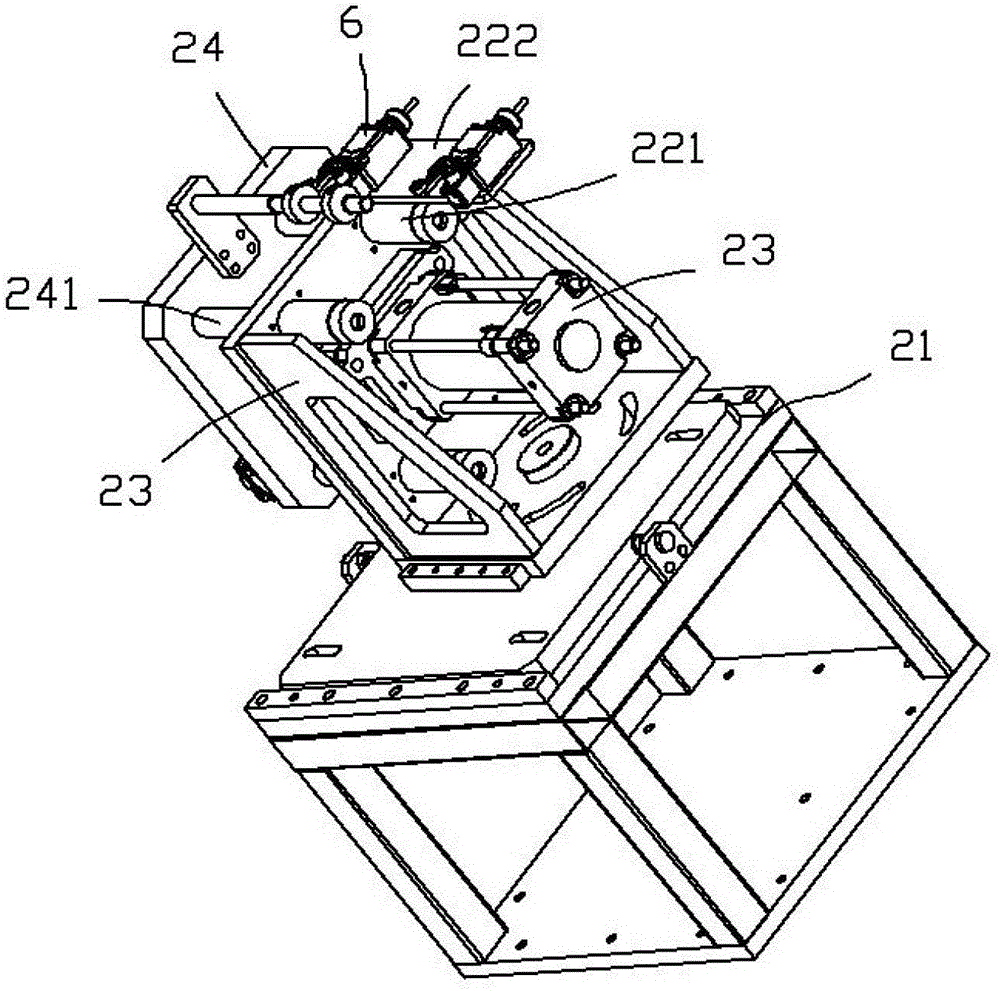

[0033] Such as Figures 1 to 14 Shown is the embodiment of a kind of cylinder end face automatic deburring machine of the present invention, and it comprises frame 1, is provided with burring station and deburring station successively on frame 1 from left to right, on frame 1 and A clamping station is arranged on the opposite side of the burring and burring station, and a shaving and deburring machine 2 and a brushing and deburring machine 3 are respectively installed on the shaving and deburring station, and a clamping mechanism is installed on the clamping station 4. In addition, a conveying mechanism is provided on the frame 1. Between the clamping mechanism 4 and the burring machine 2 is a passage for the workpiece to pass through. A cross rotation mechanism 7 is arranged at the entran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com