Rapid cutter-changing mechanism for multi-cutterhead cutting system

A tool changing mechanism and multi-head technology, which is applied in forming/shaping machines, metal processing machinery parts, special forming/shaping machines, etc., can solve the problems of time-consuming, labor-intensive, difficult to change cutter heads, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

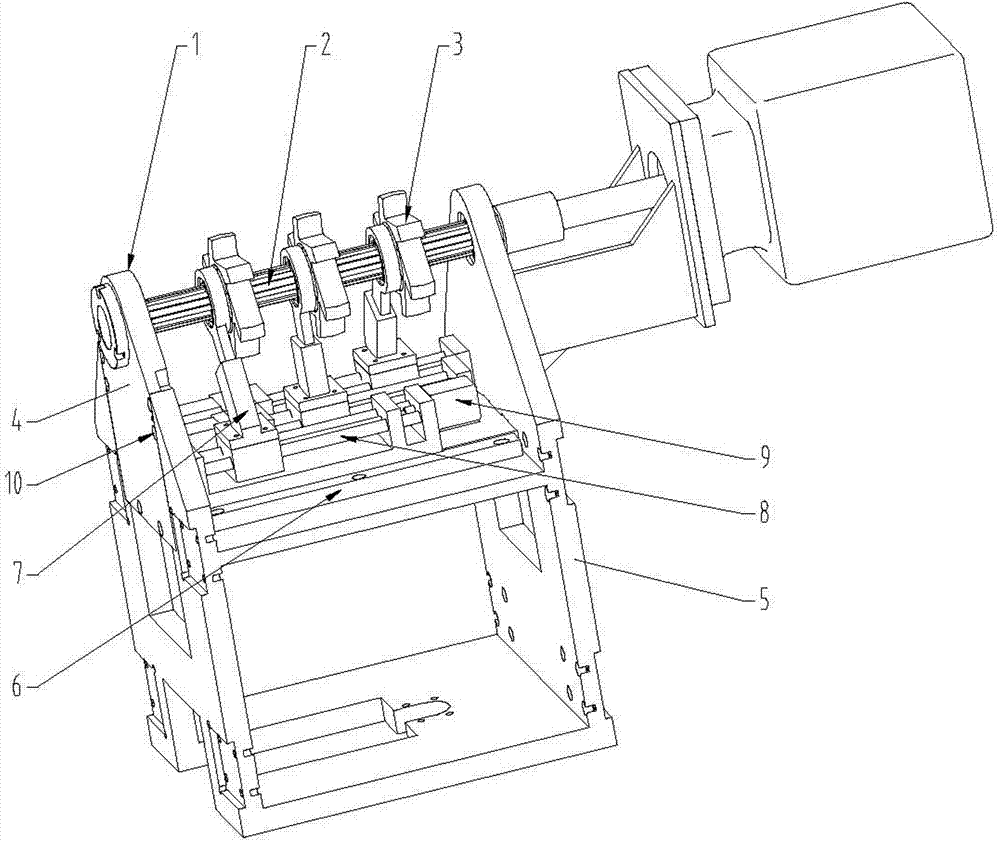

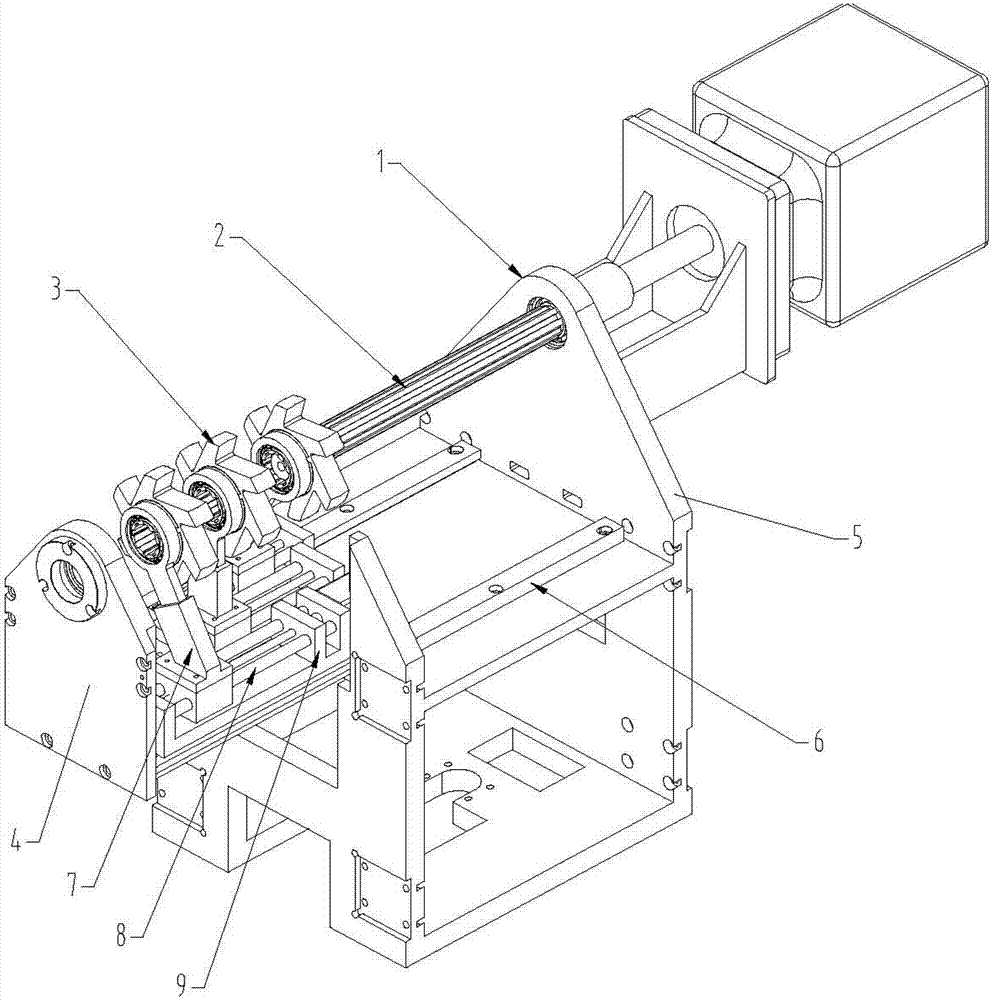

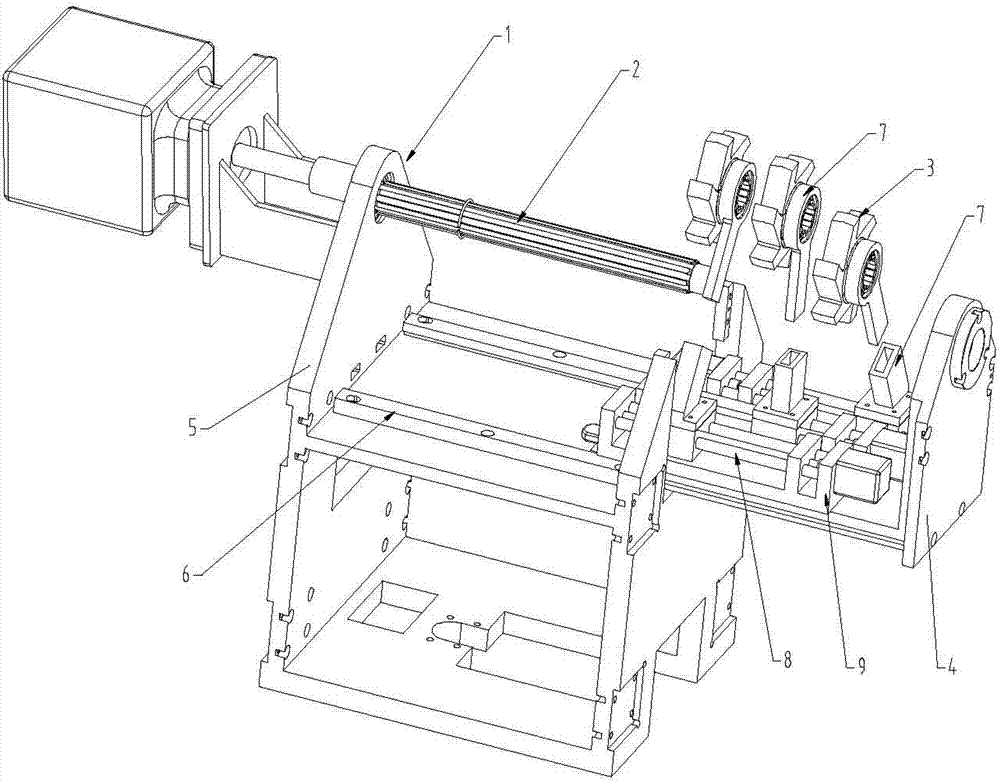

[0017] like Figure 1-3 Shown: A quick tool change mechanism for a multi-cutter cutting system, including a spindle support 1, a spindle 2 and a cutter head combination 3, a lever mechanism 7 and a linear guide pair 8, the spindle 2 is installed on the spindle support 1 and the spindle 2 A plurality of cutter head assemblies 3 are installed, and the multi-cutter head co-spindle 2 movable structure design and each cutter head assembly 3 can perform relatively independent axial movement during the cutting process. The upper part of the lever mechanism 7 and its corresponding cutter head The combination 3 is connected and the lower end of the lever mechanism 7 is slidably connected with the linear guide rail pair 8 , and the linear guide rail pair 8 is arranged on the platform of the main shaft support 1 . Wherein the spindle support 1 comprises a movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com