Method and device for producing semi-finished web and method for producing composite material

A semi-finished product and format technology, applied in applications, home appliances, other home appliances, etc., can solve problems such as complex control mechanisms and large structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

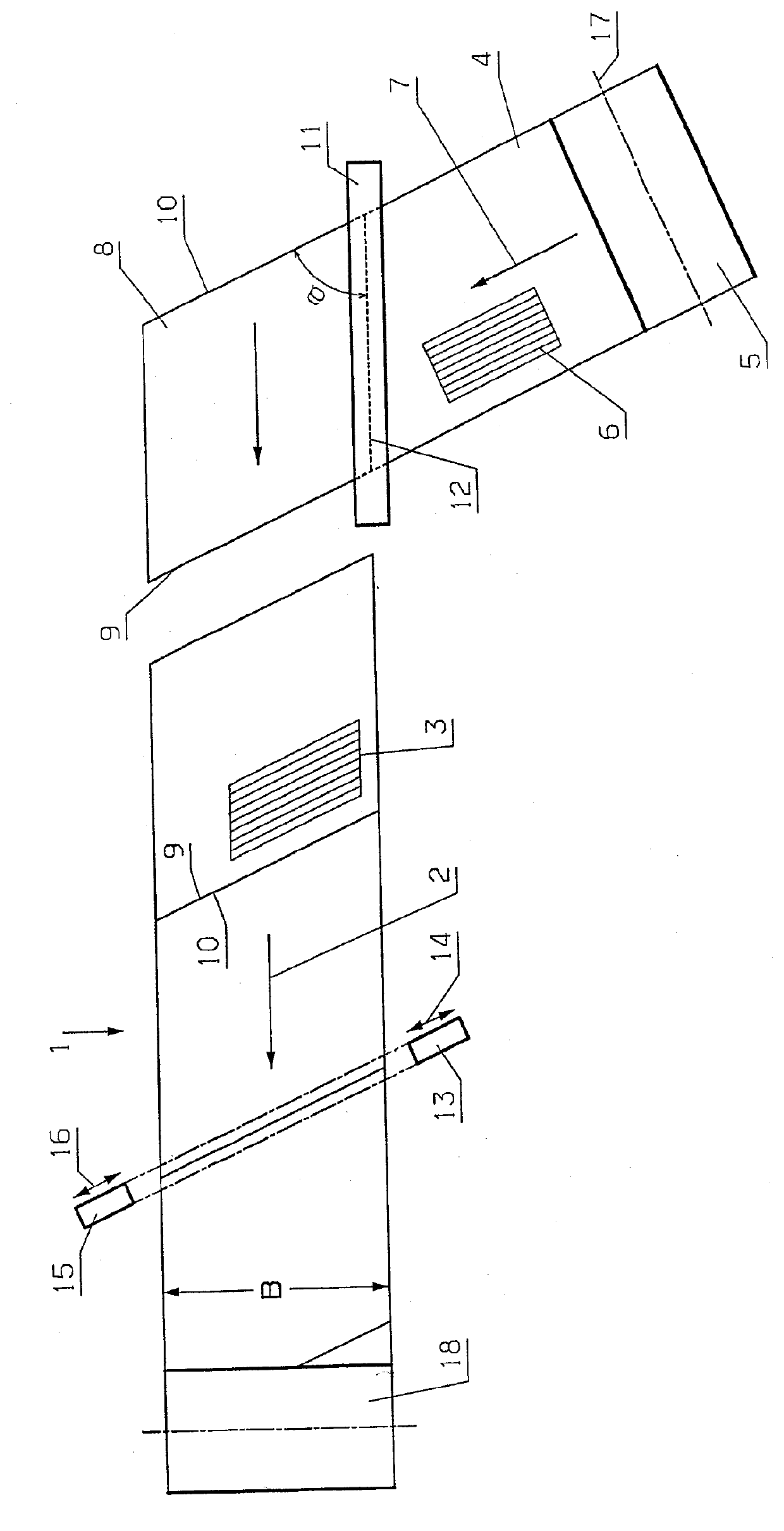

[0026]The drawing shows in a very simplified form a semi-finished web 1 with a longitudinal direction 2 indicated by an arrow and a plurality of fibers 3 fixed in a unidirectionally oriented manner. The fibers 3 run at a predetermined angle a relative to the longitudinal direction 2 . The fibers are embedded in a matrix (not shown in detail) made of plastic.

[0027] To produce such a semi-finished web, a stock web 4 is used. The supply web 4 can, for example, be unwound from a supply roll 5 . Optionally, several supply rolls 5 can also be arranged next to each other and correspondingly several supply webs 4 can be pulled down simultaneously. However, the supply web 4 can also be produced in-line. The supply web 4 can optionally also be removed in sections from a store or magazine.

[0028] As a stock web, for example, the semi-finished web described in EP 2 301 735 A2 can be used. The supply web 4 can therefore have a multiplicity of fibers 6 fixed in a unidirectional or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com