Electric braking type double-disk friction press

A friction press and electrical braking technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of increasing production costs, delaying working hours, and difficulty in operation, and achieving the effect of reducing production costs and ensuring working hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

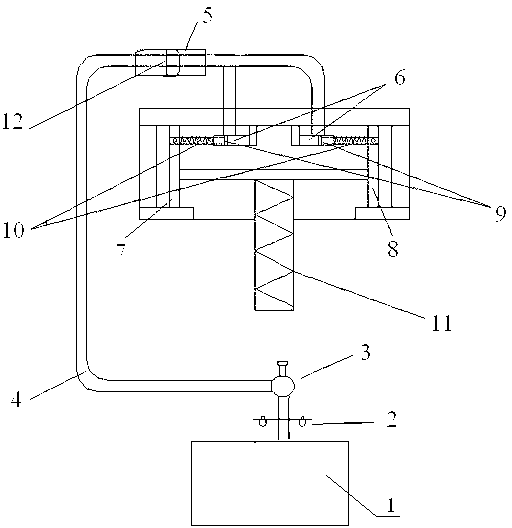

[0008] The present invention will be further described below in conjunction with accompanying drawing:

[0009] Such as figure 1 As shown, the present invention relates to an electric braking type double-disc friction press, including an air tank 1, an atomizer 2, a pressure reducing valve 3, an air pipe 4, an electromagnetic valve 5, an electromagnet 12, a brake cylinder 6, and a piston 9 , spring 10, left friction disc 7, right friction disc 8, main friction disc 11, gas tank 1 is connected with brake cylinder 6 through air pipe 4, and atomizer 2, pressure reducing valve 3 and electromagnetic valve 5 are arranged in turn on air pipe 4 , the electromagnetic valve 5 is provided with an electromagnet 12, the electromagnet 12 cooperates with the piston 9 in the brake cylinder 6, the piston 9 is connected with the left and right friction discs 7 and 8 through a spring 10, and the left and right friction discs 7 and 8 are arranged There are main friction discs 11.

[0010] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com