Screen printing device, scraper mechanism and manufacturing method for print and substrate

A technology of screen printing device and printed matter, which is applied in the direction of screen printing machine, printing machine, printing device, etc., which can solve the problems of printing quality degradation and achieve the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

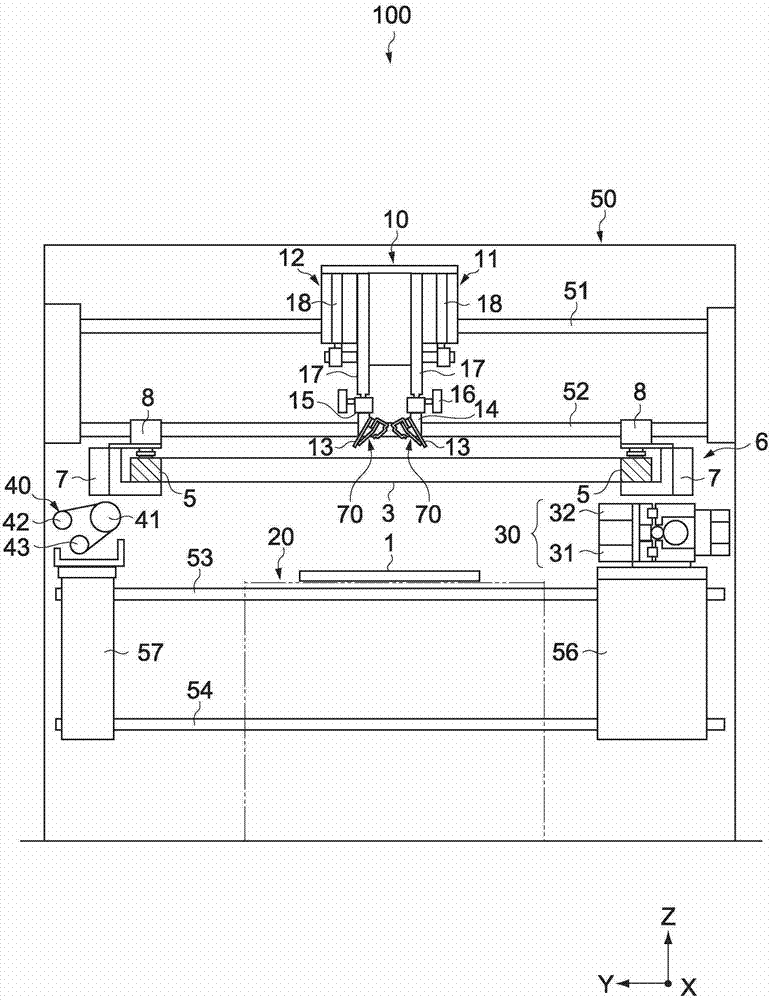

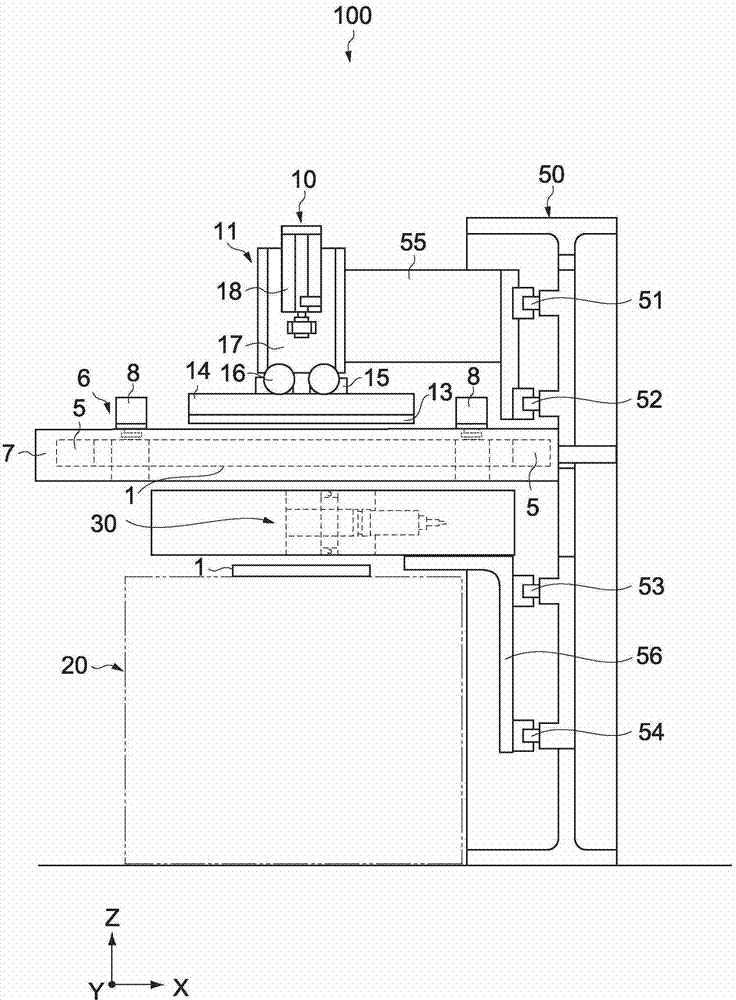

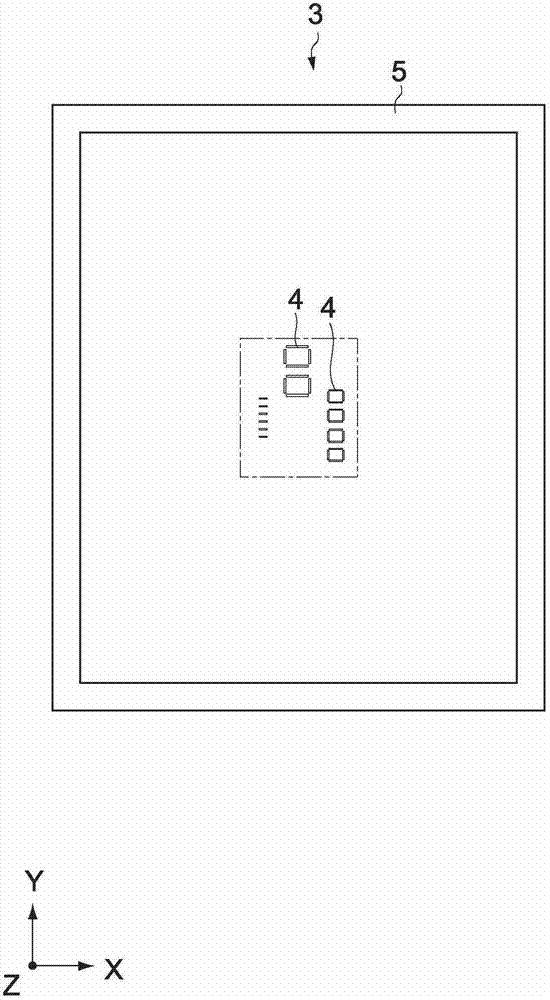

[0063] The overall structure of the screen printing device 100 and the structure of each part

[0064] figure 1 It is a front view showing the screen printing apparatus 100 according to the first embodiment of the present technology, figure 2 is a side view showing the screen printing device 100 . image 3 is a plan view showing the screen 3 included in the screen printing device 100, Figure 4 is a block diagram showing the screen printing device 100 .

[0065] The screen printing apparatus 100 shown in these figures is the screen printing apparatus 100 which prints the cream solder 2 (paste substance) on the board|substrate 1 (printing object). On the upstream side of the screen printing apparatus 100 , for example, a substrate input device (not shown) for inputting the substrate 1 into the screen printing apparatus 100 is arranged. On the other hand, on the downstream side of the screen printing device 100, a printing inspection device (not shown) that receives the subst...

no. 2 Embodiment approach

[0137] Next, a second embodiment of the present technology will be described. In the description after the second embodiment, components having the same functions and structures as those of the above-mentioned first embodiment will be given the same reference numerals, and descriptions will be omitted or simplified.

[0138] Figure 9 It is a perspective view which shows the scraper mechanism of 2nd Embodiment. Figure 10 It is a top view showing a scraper mechanism.

[0139] This scraper mechanism differs from the above-described first embodiment in that guide portions 90 are disposed on both end sides of the scraper 13 (and vibrating portion 70 ) in the width direction (direction perpendicular to the sliding direction). Other points are the same as those of the above-mentioned first embodiment.

[0140] The guide unit 90 includes a first guide 90a and a second guide 90b. The first guide 90a and the second guide 90b are made of materials such as metal and resin, and are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com