Hydraulic type composite vehicle wheel

A hydraulic and hydraulic wheel technology, applied in the direction of wheels, wheel accessories, high elastic wheels, etc., can solve the problems of tire blowout impact resistance, etc., and achieve good shock absorption performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Now in conjunction with specific embodiments, the technical solution of the present invention is further described.

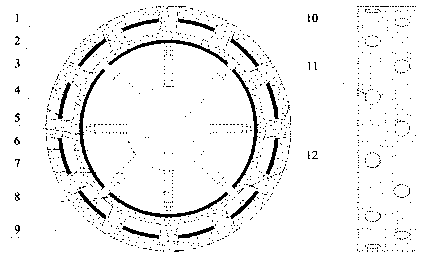

[0012] figure 1 As shown in , the hydraulic composite wheel has inner and outer wheels, the inner wheel is composed of an elastic inner steel ring 3 and an inner rubber layer 2 wrapped outside the elastic inner steel ring 3, and the inner rubber layer 2 has a conical convex The outer ring wheel is composed of the outer steel ring 1 of the wheel and the outer rubber layer 9 wrapped on the outer side of the outer steel ring 1 of the wheel, and the outer ring wheel has a first through-hole structure corresponding to the raised structure 10 of the inner ring wheel 11. At least two rows of protruding structures 10 are arranged in a staggered manner and cooperate with the corresponding first through hole structures 11 so as to improve the off-road performance and limit the relative displacement of the inner and outer ring wheels. The composite wheel is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com