A crawler frame structure

The technology of a crawler frame and a bracket is applied in the field of tail rolling machines, which can solve problems such as rotation, and achieve the effect of stable hoisting process of heavy objects and uniform overall stress state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

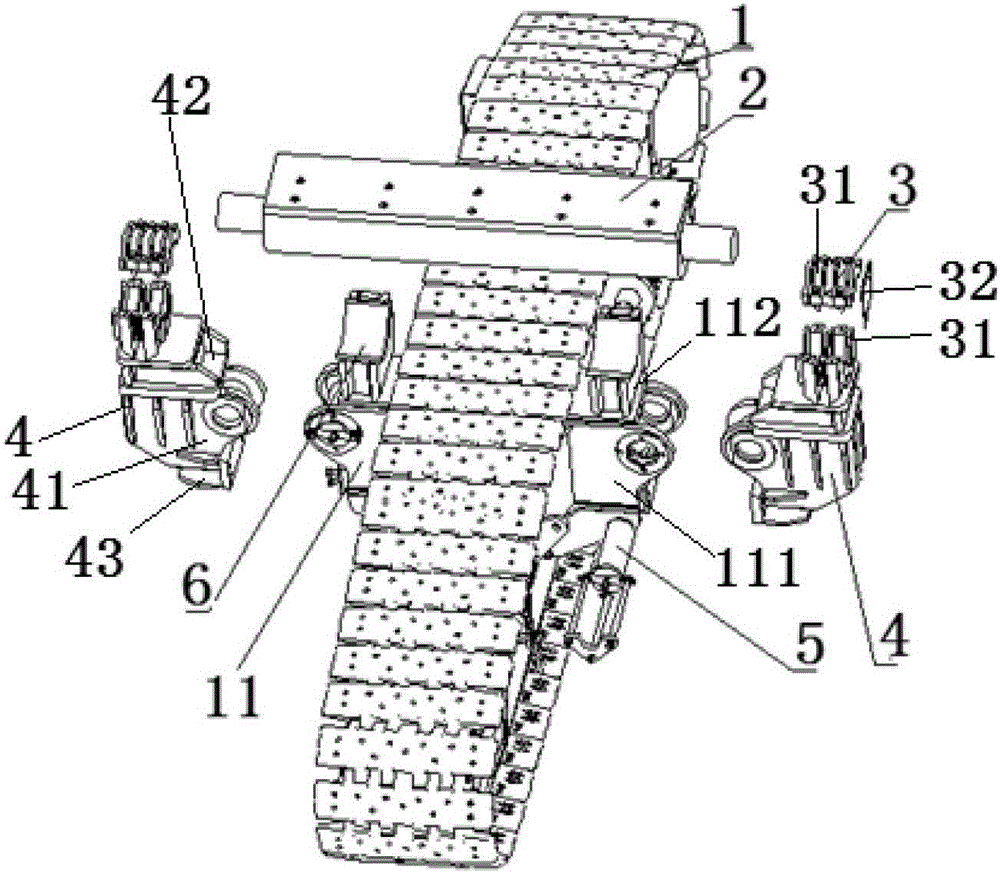

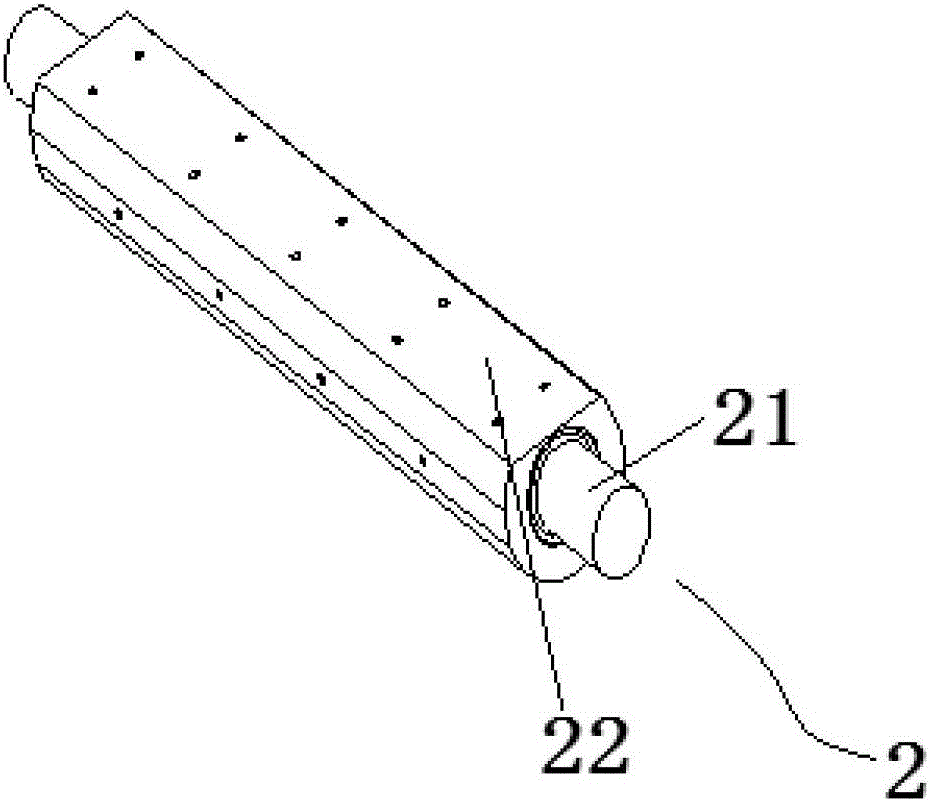

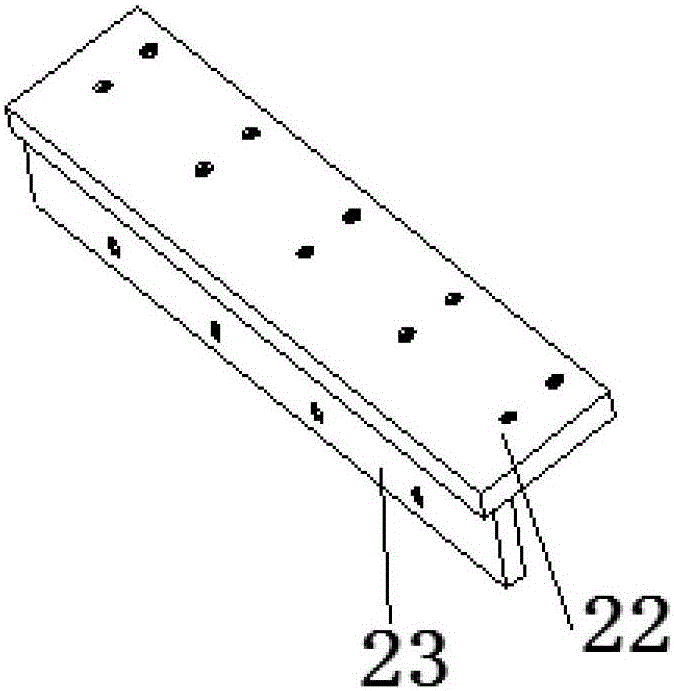

[0025] like Figure 1-5 As shown, the crawler frame structure provided by the present invention includes a crawler frame 1, a rotating load-bearing beam 2, a support mechanism 3 and a support 4, wherein: the two sides of the crawler frame 1 are respectively fixedly connected with a connecting mechanism 11, and the two support 4 They are respectively connected with the connecting mechanisms 11 on both sides of the crawler frame 1 . A support mechanism 3 is provided on the top surface of each support 4 . The support mechanism 3 has a through hole, and the axes of the through holes on the two support mechanisms 3 coincide. The two ends of the rotating load-bearing beam 2 penetrate into the through holes of the two support mechanisms 3 and are rotatably connected with the support mechanisms 3 . The supporting mechanism ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap