Structure and construction method of self-insulating exterior walls and beams and columns with the same life span

A self-insulation and life-span technology, applied to building structures, walls, building components, etc., can solve problems such as irrationality, reduce the stability of houses and earthquake resistance, achieve low investment in transformation, and be conducive to resisting temperature Alternative ability, the effect of reducing the center of gravity of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

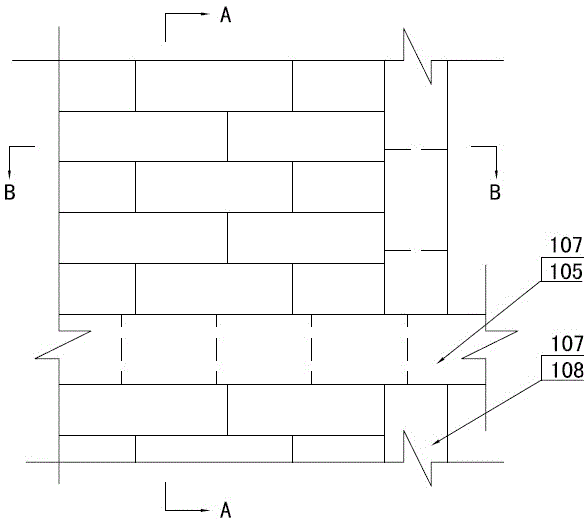

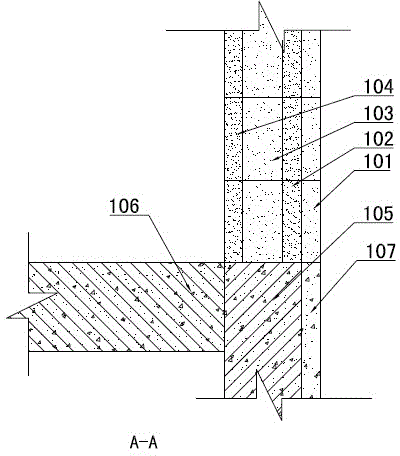

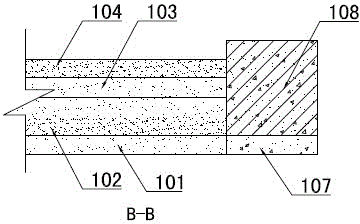

[0033] The structure of the same life, self-insulating external wall and beams and columns, including the wall filled with frame structure. The wall consists of 4 layers from the outside to the inside, followed by the outer insulation layer 101, the outer bearing layer 102, the center layer 103 and The inner bearing layer 104; the outer bearing layer 102, the center layer 103 and the inner bearing layer 104 are located on the upper part of the frame beam 105; the interface between the outer insulation layer 101 and the outer bearing layer 102 and the frame beam 105 and frame column 108 The outer surface of the outer thermal insulation layer 101 protrudes to the outside of the frame beam 105, and its outer surface is flush with the outer surface of the frame beam 105 and the additional thermal insulation board 107 on the frame column 108.

[0034] The wall is masonry made of autoclaved aerated concrete blocks. The blocks used in the same wall have external insulation layer 101, ext...

Embodiment 2

[0039] In severe cold areas, energy saving on external walls requires higher thermal resistance. The thickness of the outer thermal insulation layer 101, the outer bearing layer 102, the central layer 103 and the inner bearing layer 104 are 80mm, 60mm, 190mm and 30mm respectively. Example 1 is the same.

Embodiment 3

[0041] In earthquake-prone areas, for buildings with earthquake-resistant magnitude 8 and crack degree 9, the thickness of the outer insulation layer 101, the outer bearing layer 102, the central layer 103 and the inner bearing layer 104 are 50mm, 60mm, 140mm, 50mm, respectively; The density of the outer bearing layer 102 and the inner bearing layer 104 is 950KG / M 3 , The amount of cement in the pouring mix is increased by 5%, and the other settings are the same as in Example 1.

[0042] The construction method of the structure of the same life, self-insulating external wall and beams and columns includes the following steps:

[0043] 1. Set the outer insulation layer 101, the outer bearing layer 102, the center layer 103 and the outer wall of the outer wall block according to the nature, size and engineering construction specifications of the outer wall, the arrangement of the outer wall masonry blocks, and the deviation of the construction process. The thickness, strength and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com