DC test method and test platform for arrester based on voltage compensation

A DC test and voltage compensation technology, which is applied in the direction of instruments, measuring electricity, and measuring electrical variables, etc., can solve problems such as error-prone and complicated fabrication, and achieve the effects of saving man-hours, facilitating tests, and shortening test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

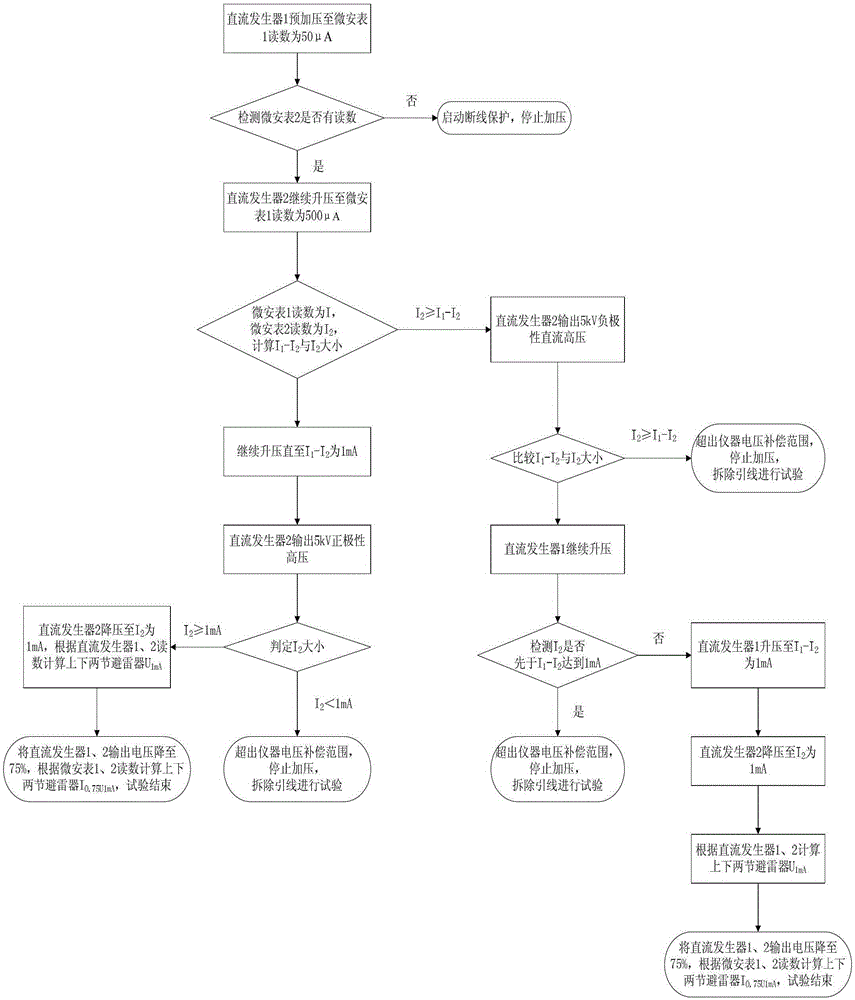

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] The voltage-compensated 220kV and above surge arrester DC test method of the present invention shortens the DC test time of 220kV and above surge arresters, improves work efficiency and can carry out the DC test of two-section surge arresters without removing the lead wires after one pressurization, compared with the traditional surge arrester without removing the lead wires. The DC test method saves 50% or more man-hours and improves work efficiency. The specific implementation process, such as figure 2 shown, including the following steps,

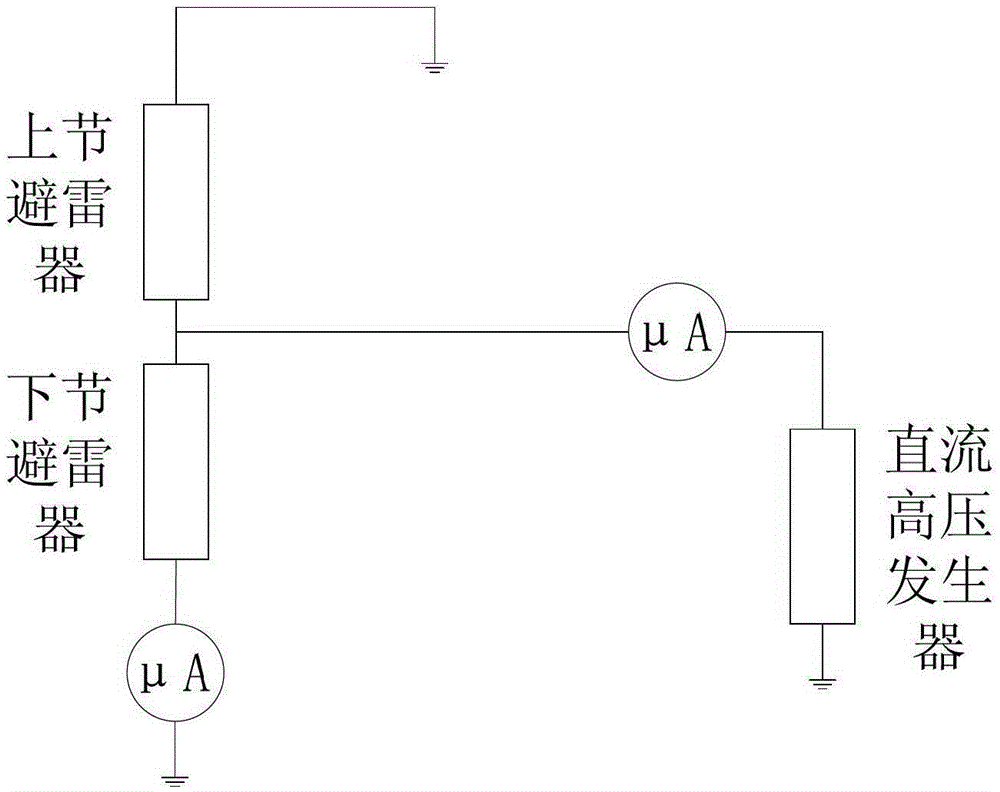

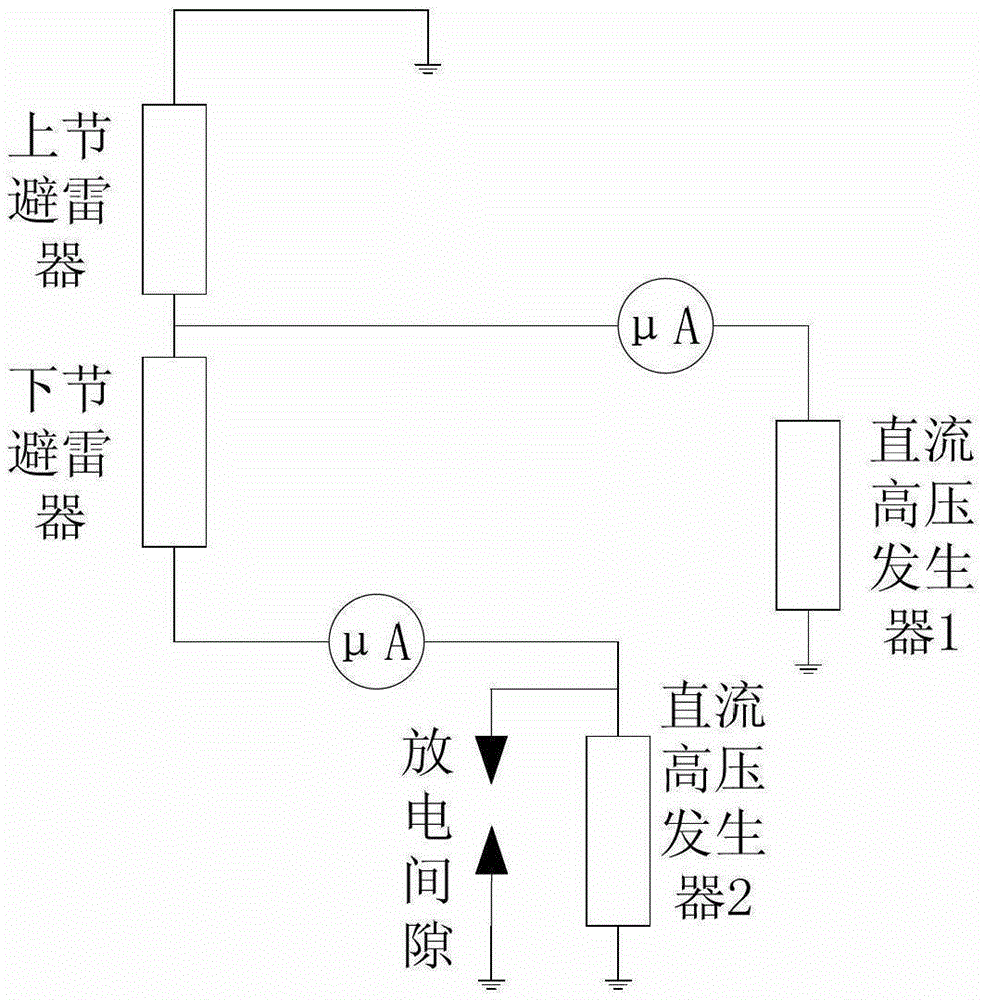

[0034] Step (a) Connect the test platform for the DC test of the arrester

[0035] At the flange between the upper and lower arresters, connect the first microammeter to apply negative DC high voltage through the negative DC high voltage transmitter; connect the end of the arrester to the second microammeter, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com