Essence of pickled Chinese cabbage and preparation method and application thereof

A technology for essence and sauerkraut, applied in the field of essence, can solve the problems of few kinds of flavor essence, volatile, heat-labile and the like, and achieve the effects of stable aroma quality, good temperature resistance and realistic aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

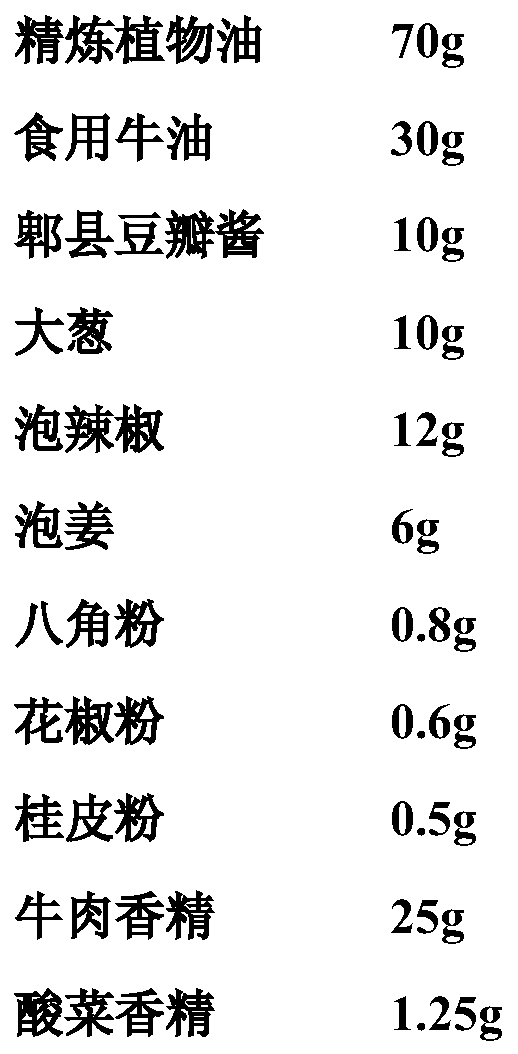

Image

Examples

Embodiment 1

[0025] Example 1: A sauerkraut flavor, prepared according to the following method: first add 53.628g of soybean oil as a solvent, heat to 60°C, add 4-hydroxy-2,5-dimethyl-3(2H)furanone 0.04g, 0.07g acetylpyrazine, stir until completely dissolved, and cool to below 30°C; then add ethyl acetate 0.04g, ethyl caproate 0.04g, ethyl lactate 0.09g, butyl caproate 0.17g, 0.18g of hexyl 2-methylbutyrate, 0.04g of phenethyl acetate, 0.03g of trans-2-heptenal, 0.18g of phenethyl alcohol, 0.01g of p-ethylphenol, 0.08g of dimethyl disulfide , Acetic acid 0.52g, propionic acid 0.09g, butyric acid 0.08g, 2-methylbutyric acid 0.06g, garlic oil 0.70g, cumin oil 1.00g, ginger oil 2.60g and pepper extract 4.60g, and finally add the remaining 35.752g of soybean oil, mix well and fill it. The raw material components used in this embodiment can be purchased from the market, among which 4-hydroxy-2,5-dimethyl-3(2H)furanone is a commercially available product, furanone. The sauerkraut flavor prepare...

Embodiment 2

[0026] Example 2: The ratio for producing 100g of sauerkraut flavor is:

[0027] Ethyl acetate 0.06g

[0028] Ethyl caproate 0.06g

[0029] Ethyl lactate 0.12g

[0030] Butyl caproate 0.17g

[0031] Hexyl 2-methylbutyrate 0.20g

[0032] Phenylethyl acetate 0.06g

[0033] Trans-2-heptenal 0.05g

[0034] Phenylethanol 0.18g

[0035] P-ethylphenol 0.03g

[0036] 4-hydroxy-2,5-dimethyl-3(2H)furanone 0.04g

[0037] Acetylpyrazine 0.07g

[0038] Dimethyl disulfide 0.08g

[0039] Acetic acid 0.52g

[0040] Propionic acid 0.09g

[0041] Butyric acid 0.10g

[0042] 2-methylbutyric acid 0.08g

[0043] Garlic essential oil 0.70g

[0044] Cumin oleoresin 2.00g

[0045] Ginger essential oil 3.60g

[0046] Sichuan pepper essential oil 4.60g

[0047] Sunflower seed oil 87.19g

[0048] Total: 100g

[0049] Production process: first add 60% of the above-mentioned sunflower seed oil weight as a solvent, after heating to 60°C, add the above-mentioned weight of 4-hydroxy-2,5-dimethyl-3(2H)furanone and acetylpyrazine, Stir ...

Embodiment 3

[0050] Example 3: A sauerkraut flavor, prepared according to the following method: first add 57.858g of palm oil as a solvent, heat to 60°C, add 4-hydroxy-2,5-dimethyl-3(2H)furanone 0.01g, 0.01g acetylpyrazine, stir until completely dissolved, and cool to below 30°C; then add ethyl acetate 0.01g, ethyl caproate 0.1g, ethyl lactate 0.01g, and butyl caproate 0.05g, 0.18g of hexyl 2-methylbutyrate, 0.02g of phenethyl acetate, 0.01g of trans-2-heptenal, 0.05g of phenethyl alcohol, 0.01g of p-ethylphenol, 0.01g of dimethyl disulfide , Acetic acid 0.10g, propionic acid 0.05g, butyric acid 0.05g, 2-methylbutyric acid 0.10g, garlic oil 0.10g, cumin oil 3.00g, distilled ginger oil 1.00g and Chinese pepper oleoresin 5.00g, add at the end The remaining palm oil is 38.572g, stir it evenly and fill it up. The sauerkraut flavor prepared in this example is used in convenience foods, such as seasoning packets of instant vermicelli.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com