Fanless cooling device for 3d printers and fdm high-speed 3d printers

A technology of 3D printer and cooling device, applied in the field of 3D printing and 3D printer structure, can solve the problems of extrusion nozzle vibration, affecting printing accuracy, surface ripple of printing model, etc., to avoid vibration problems, low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

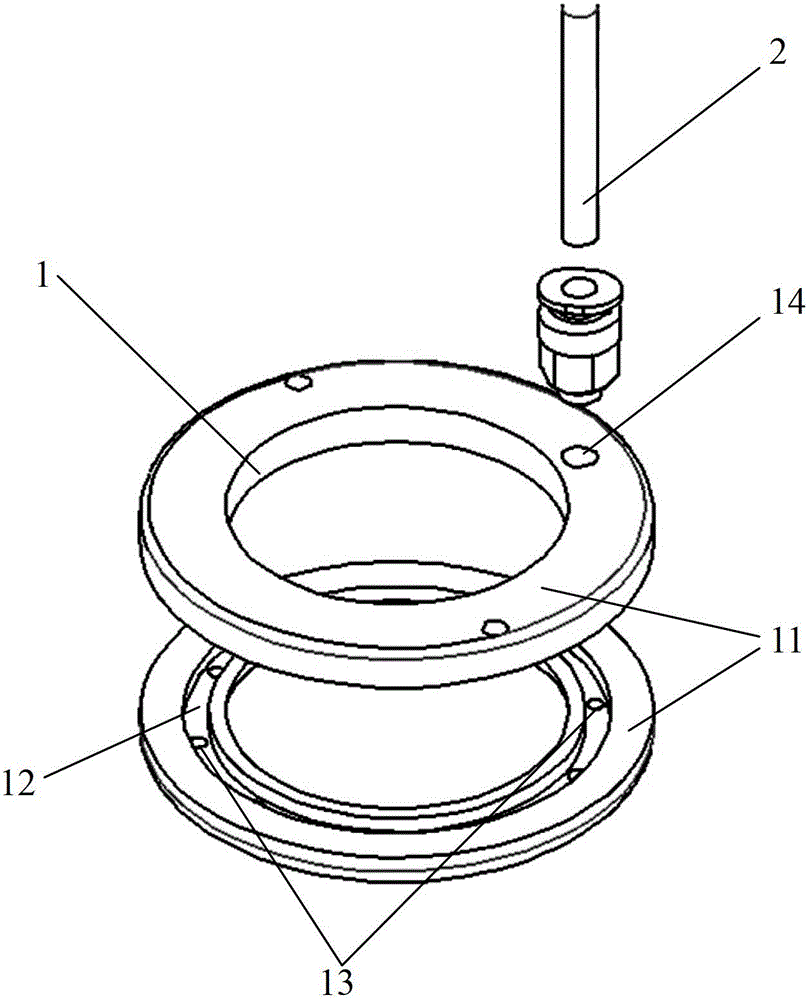

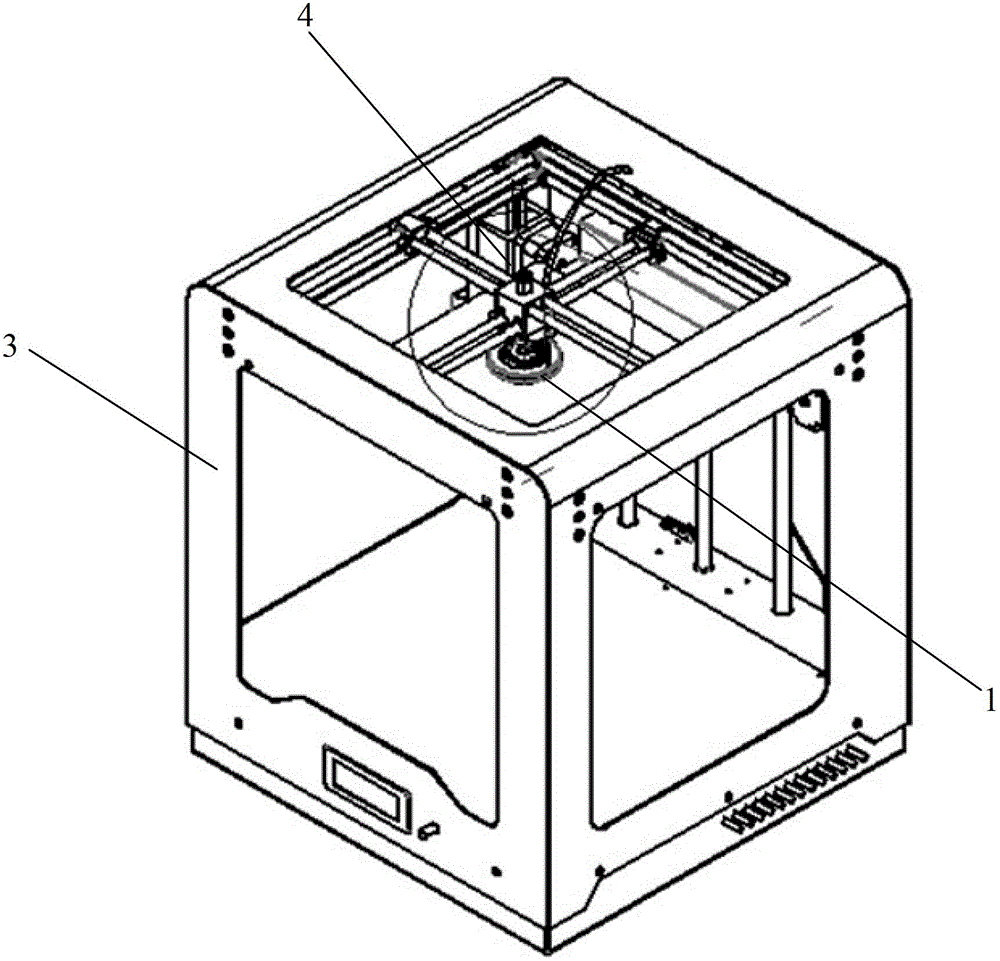

[0020] see figure 1 As shown, the present invention is a schematic diagram of the disassembled structure of the fanless cooling device applied to the 3D printer of the present invention.

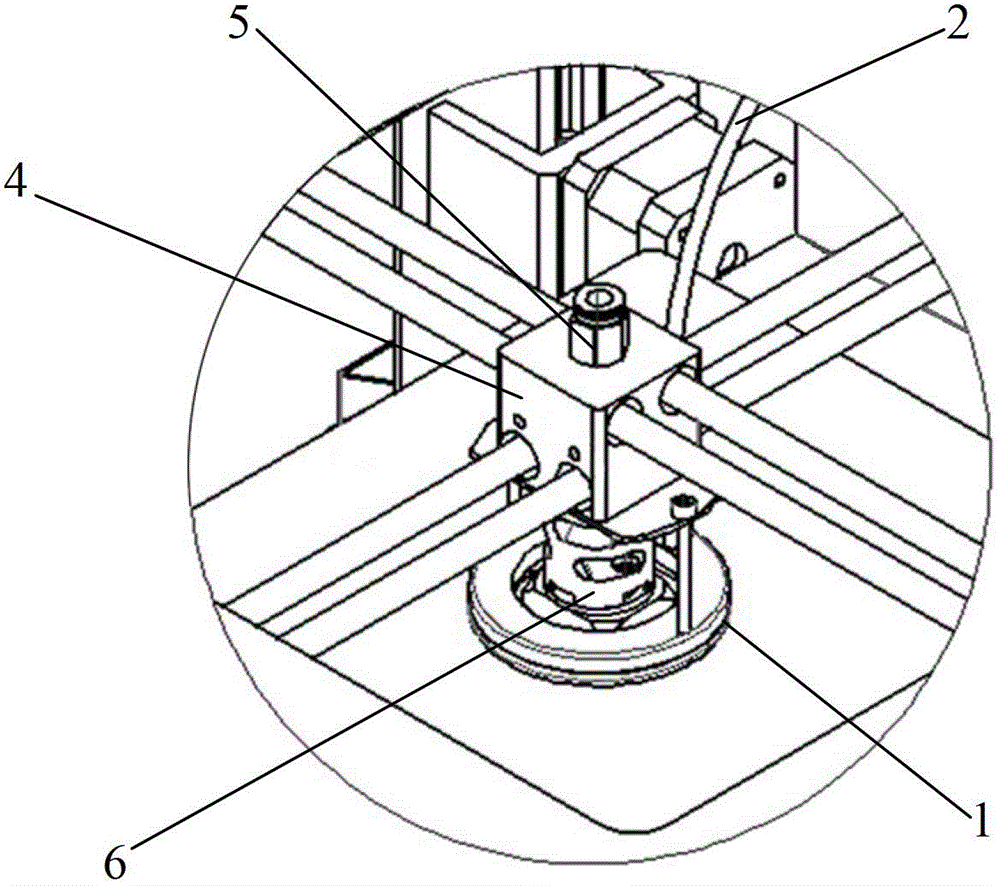

[0021] In one embodiment, the fanless cooling device applied to a 3D printer includes an air outlet 1, an air pump (not shown in the figure) and an air pump control module (not shown in the figure) for controlling the air pump, the The air pump control module is connected to the air pump, and the air pump communicates with the air outlet 1 through the pipeline 2, and the air outlet 1 is arranged at a position near the extrusion nozzle 6 of the 3D printer.

[0022] In a more preferred embodiment, the air outlet 1 includes an annular body 11, and the annular body 11 of the air outlet 1 is arranged around the extrusion nozzle 6 of the 3D printer. The annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com